experimental investigation of improving boron reactivity in reduction

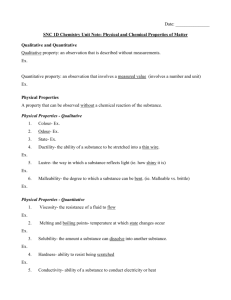

advertisement

EXPERIMENTAL INVESTIGATION OF IMPROVING BORON REACTIVITY IN REDUCTION OF BORON-BEARING IRON CONCENTRATE Y. X. Han Northeastern University Shenyang, China (*Corresponding author: dongdafulong@mail.neu.edu.cn) J. W. Yu Northeastern University Shenyang, China E-mail address: neu_mpc237@163.com. Y. J. Li Northeastern University Shenyang, China E-mail address:liyanjun@mail.neu.edu.cn. P. Gao Northeastern University Shenyang, China gaopeng@mail.neu.edu.cn. J. Liu Northeastern University Shenyang, China liujie@mail.neu.edu.cn. Y. S. Sun Northeastern University Shenyang, China E-mail address:neusunyongsheng@163.com. EXPERIMENTAL INVESTIGATION OF IMPROVING BORON REACTIVITY IN REDUCTION OF BORON-BEARING IRON CONCENTRATE ABSTRACT The boron-bearing iron concentrate was extracted from the paigeite ore by the process of magnetic-gravity separation. In order to fully utilize the refractory ore and meet the boron consumption of China, a novel process for separation of boron from iron in boron-bearing iron concentrate was proposed in this paper, and laboratory scale experiments of improving boron reactivity were performed in particular. Fine boron-bearing iron concentrate briquettes were reduced by bituminous coal completely at 1398 K for 150 min. The effect of sodium carbonate, which was used as an additive in the roasting processing, was investigated. The addition of sodium carbonate decreased the boron reactivity and facilitated the volatilization of boron. The influence of divers cooling methods of the reduced samples on the boron reactivity was studied. The results indicated that the boron reactivity of the reduced samples was 80.76% when they were cooled by the rapid water quench method. In addition, the magnetic material containing 92.81 % Fe with a recovery of 95.58 % and boron-rich non-magnetic material containing 14.11% B2O3 with a recovery 89.59% could be obtained by low-intensity magnetic separation. The magnetic material and boron-rich non-magnetic material were good raw materials for steel-making and borax production. Figure 1 – Effect of dosage of sodium carbonate on the reactivity of boron Figure 2 – Effect of diverse cooling methods on the reactivity of boron KEYWORDS Boron-bearing iron concentrate, Solid direct reduction with magnetic separation, Metallic iron powder, Boron-rich non-magnetic material, Boron reactivity