Permit to Work Policy

advertisement

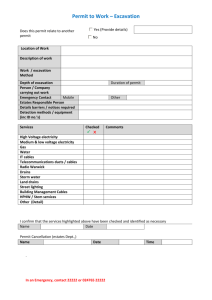

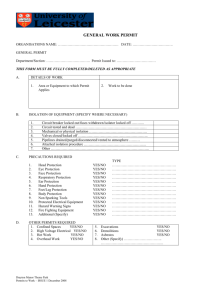

Permit to Work Procedure Area Issuing Department Document # Approved by Revision # Date Page General Safety SSP0004 Wade Gauthreaux/Jeff Warmann 2 8/05/11 3 0f 6 Purpose Safety References Definition Responsibilities To adequately define and document Murphy Oil USA Inc. expectations in respect of ensuring that a safe system of work is determined and agreed prior to any non-routine and/or contractor works being performed at an operating facility. Specifically, this process seeks to detail expectations in respect of the Permit to Work System to be used by trained and competent personnel to ensure that appropriate and adequate safeguards are taken to protect personnel from harm Any work performed at the Meraux Refinery requires strict adherence to every detail outlined in this policy. Any deviations require the approval of the Safety, Operations, and Plant Managers through SSP0029. OSHA 1910.119 PPE The work permit is a written document authorizing certain people to carry out specific work at a particular location for a specific time period and should be issued to all contractors working at Murphy Oil USA Inc. operating facilities and / or employees carrying out specified non routine work Leadership in Safety is Everyone’s Responsibility. We Must ALL ensure that we are executing work activities per this policy. Safety Manager Assigned responsibility for ensuring that the expectations in respect of the Permit to work procedure are adequately defined and documented, and thereafter, that the process is effectively implemented and maintained. In addition they will ensure that employees and contractor personnel are provided with Work Permit training, as appropriate to their roles within the permit system Plant Manager Assigned responsibility for ensuring expectations and requirements in respect of the Permit to Work procedure are effectively communicated throughout the facility and that there is strict compliance with the documented expectations Boots-Steel Toe/Chemical Fall Protection (Not Required) Standard (SSP-0000) Eyes-Welding/Face Shield Clothing-FRC Clothing-Welding/Chemical Gloves – Welding/Chemical Respirator-Per MSDS SCBA-Per MSDS/Stand By Review applicable MSDS Use Work Permit System Overview The Permit to Work system will be will be segregated into four different work classifications, Safe Work, Low Energy, Hot Work, and Confined Space. A Safe Work Permit is required for all Non-Routine works carried out by facility personnel (operational and/or maintenance). All work activities carried out by contractors not involving hot work and/or confined space entry. Any works deemed by a Murphy Supervisor to require a safe work permit to control the work. Note Non-Routine work is any work activity that is not defined within an operating procedure or standard operating protocol. Low Energy Work will be issued on a safe work permit with the inclusion of gas testing and documentation. Low Energy work includes all vehicle entry into process areas, all electrical operated equipment, all non-intrensicly safe battery operated equipment. Hot Work Permit is required for any activity generating sparks, open flames, or intense heat capable of igniting any flammable or combustible material. This would include acetylene or gas burning, welding, brazing, grinding, abrasion blasting, soldering, and any other activity requiring a fire watch to be present. Confined Space Permit is required entry into any space that is large enough and so configured that a person could enter and perform work, has limited or restricted means of entry or exit, contain or has potential to contain a hazardous atmosphere, contains material that has potential for engulfing or asphyxiating the entrant, and is not designed for continuous human occupancy. Work permits will be valid for the duration of one shift or as indicated on the expire time. Permit extensions to the next shift are acceptable after proper communications with the oncoming shift operator, validation that the equipment and permit status is unchanged, and all appropriate permit extension signatures are documented on the permit. Permit Form Design, Content, Expectations - Safe Work / Low Energy Permits will have a white background with Black print, Hot Work will be white with Red print, Confined Space Permit will have Green print. Each permit will be carbon copied with the Permit Issuer retaining the original copy and the Permit Holder posting the hard copy at the job site. Each permit will have common sections with specific criteria pertaining to the type permit; 1. Permit requester/holder section. This section will include the following; Company or Contractor name, Area or unit in which the work will occur, Permit requester/holders name, Equipment identification number, The number of persons working under the permit, The work order number, The scope of the proposed task, a tools and equipment needed checklist, and signature spots for the requester/holder and the issuer to sign indicating the scope of the task is clearly identified and understood by both parties. 2. A section to identify the previous product that was in the equipment, a reminder to review the Material Safety Data Sheet for specific information about the product if you are not sure about exposure consequences and personal protective equipment requirements 3. Pre-work section to identify the status of the equipment, how it was isolated, decontaminated, and lock out tag out status. The permit issuer and the permit requester/holder are expected to review these items together at the job location. 4. A job hazard analysis section / checklist with standard control measures as well as a section for specific job hazards and additional control measures and/or special instructions. The permit issuer and the permit requester/holder are expected to review these items together to be sure they both understand and agree with all actions required to perform the task Safely. 5. A personal protective equipment checklist. The permit issuer identifies required PPE based on potential exposure and conditions. 6. An atmospheric testing and documentation section. Atmospheric testing should be performed on equipment prior to allowing work to proceed on equipment if it was exposed to hydrogen sulfide, benzene, butadiene, carbon monoxide. LEL is required to be tested for low energy, hot work, and confined space permits. 7. An authorization to work signature section indicating all parties have reviewed the job scope, understands and reviewed the conditions of the equipment, and will comply with all hazards, control measures, and PPE requirements. 8. An additional signature section to extend the permit into the next shift. A review of the job and permit conditions with all parties is required. 9. A work complete section for the permit holder and issuer to review the job for completeness, housekeeping, safe condition, and sign off as complete. 10. The back of the permit has clairfication instructions for each section of the permit. Roles and Responsibilities Permit Requestor / Holder - The person requesting a work permit will ensure that the following expectations are effectively met:- The work permit is requested in a timely manner to allow a review of the proposed work and work area The scope of the proposed work, the equipment to be used, the associated hazards, the proposed hazard mitigation measures and the identified safe method of working are defined Permit to Work Procedure Area Issuing Department Document # Approved by Revision # Date Page General Safety SSP0004 Wade Gauthreaux/Jeff Warmann 2 8/05/11 3 0f 6 - The workplace is prepared for inspection prior to authorization of the permit The procedures to be followed (safe method of working) are effectively communicated to all those involved in the performance of the works The workplace is regularly inspected during the course of the work to ensure that activities are being performed in accordance with the safe method of working and that safe work practices are being used The workplace is inspected prior to signing-off the permit to ensure that the scope of work has been effectively achieved and that the plant, equipment and/or work area has been left in a safe condition Permit to Work – Contractor Management - If the proposed work is to be carried out by contractors the Contractor’s representative will ensure that the following expectations are effectively met Those employees assigned to the proposed work:o Have been given the appropriate training and understand the operation of the permit to work system and their specific responsibilities within it o Are trained and competent to perform the tasks assigned to them - Plant and/or equipment supplied to perform the tasks assigned are adequately maintained, certified as applicable and remain fit for purpose during the duration of the proposed work Permit to Work – Permit Issuer The person issuing the work permit will ensure that the following expectations are effectively met - They are a trained and competent employee of the operating unit - The nature of the work is fully understood - The hazards associated to the work are identified - All hazard mitigation measures are effectively implemented prior to the work starting - Any permits issued for other tasks that may interact are cross referenced - The equipment and workplace is adequately prepared prior to authorizing the permit The safe method of work is available, reviewed and understood by those performing the work Any testing, including atmospheric monitoring are carried out and recorded prior to permit issue The plant, equipment and/or work area is inspected prior to signing off the permit A suitable hand-over is performed at the time of shift change to ensure that all ongoing or suspended permits are discussed with the Issuing Authority Permit to Work – Permit Holder The permit holder will ensure that the following expectations are effectively met:- They have received instruction in the permit to work system - The people working for them have received adequate training in the permit to work system - They have fully discussed the proposed work with the Permit Issuer - The work party is briefed on the details of the permit and its control measures - The plant, equipment and/or work area are prepared and safe to start the proposed work - Those assigned tasks within the scope of the proposed work are fully briefed on the details of the permit and associated control measures - Safe working practices are adopted throughout the duration of the assigned work - The control measures are maintained throughout the work activity - The plant, equipment and/or work area is inspected prior to signing off the permit - On completion or suspension of work, the site is left in a safe condition and the Permit Issuer advised accordingly Permit to Work – Those Carrying Out Work Those carrying out the work will ensure that the following expectations are effectively met:- They have received training in, and have good understanding of, the permit to work system - They do not start any work requiring a permit until it has been properly issued - They receive a briefing from the permit holder on the particular task and the precautions to be followed - They follow the conditions specified on the permit - When they stop work, the site and any equipment is left in a tidy and safe condition - If in any doubt, or if circumstances change, they stop work and consult the Permit Issuer Safe Work Permit Specifics - Safe work permits will be issues for all non-routine work which is any work activity that is not defined within an operating procedure or standard operating protocol. Safe work permit exceptions 1. Operators performing routine work within their unit of qualification. 2. Operation supervisors or specialist assisting operators. 3. Maintenance personnel evaluating or planning work, no physical work involved, unit sign in required. 4. Managers, Safety, or Health and Safety Committee performing audits, unit sign in required. 5. Inside of maintenance shops on jobs NOT requiring lock out tag out. If LOTO is required, the maintenance supervisor or qualified designee will issue the permit. Permit to Work Procedure Area Issuing Department Document # Approved by Revision # Date Page General Safety SSP0004 Wade Gauthreaux/Jeff Warmann 2 8/05/11 3 0f 6 Hot Work Permits Operations Responsibilities Prior to issuing Any hot work permits, shall determine the flammable materials and hazardous areas present in their work location. Evaluation of the work area will be performed by using a Combustible Gas analyzer. Zero percent of the lower explosive level is the goal of this facility for Hot Work. This atmospheric check for combustibles will be performed as many times as deemed necessary by the authorizing person and readings shall be annotated on the Hot Work Permit form. For welding operations the atmospheric check will include the area where the welding machine ground connection is made. Will protect flammables from ignition by the following methods, in this preferred order: Have the work moved to a safe location free of flammable materials. (Welding Fab Areas) Have flammables and combustibles moved to a safe distance of thirty five feet (35’) from the "Hot Work" site or properly shield flammables and combustibles from ignition sources. Assure that "Hot Work" is so scheduled that plant operations which might expose flammables to ignition are not started during "Hot Work". (Start-up, shutdown, draining or depressurizing equipment). Shall issue authorization, in the form of a "Hot Work Permit", for any work activity that may cause ignition. Determine the proper fire protection and extinguishing equipment needed. Determine the need for the number of fire watchers, their placement, and assure their availability at the work site. Shall check on job progress periodically during the work shift. Hot work jobs will be evaluated jointly by the unit and chief operators. Permits will be issued by the chief operator. Area three hot work permits will be prepared and gas tested by the operator, reviewed with another area 3 qualified hot work permit operator or operations supervisor and signed by a qualified permit writer as the issuer. Pressure rated blinds are required for hot work. Exceptions can be made utilizing deviation procedure SSP0029 with mitigations in place. The chief operator or qualified gas tester will perform and document gas testing. Required for every hot work permit. Target LEL is 0%. Four signatures are required for hot work, Permit Holder, Chief Operator, Unit Operator, and the Fire Watch. If a hot work job is stopped due to a release, incident, or for more than two hours, gas testing must be complete before starting work again. Equipment Preparations for Hot Work Pipes and containers shall be isolated utilizing lockout/tagout (PolicySSP-0001) and by means of blinding/blanking, squat line plugs (test plugs), to prevent flammable contaminants from entering the affected hot work area. Blinds shall be meet minimum thickness requirements per ANSI flange rating standards. See chart below. Steam lines that have no flanges or means of blinding can be double blocked and bled. If only single isolation can be accomplished, the isolation valve must provide a positive seal to prevent steam leakage to the affected work area. If steam leakage is excessive, alternate repair options will be considered. Standard gas testing must indicate zero combustibles. Gas freeing of this equipment is essential. Gas freeing can be performed by washing, steaming, chemical cleaning, and/or nitrogen purges. The Chief Operator will verify the equipment was decontaminated utilizing the appropriate method. Analyzing equipment should be used to insure that explosive atmospheres do not exist. Gas testing analyzers must be calibrated prior to testing equipment for hot work. Any hot work trained and qualified operator can perform the gas testing and initial next to the test results. The Chief Operator must verify the gas testing results. High pressure plugs designed to isolate open ended piping from potential hazards. Maximum operating pressures of these plugs are: 1/2" - 1-1/4" 5000 psig. 1-1/2" - 2-1/2" 4000 psig. 3" - 3-1/2" 3500 psig. 4" 3000 psig. 4-1/2" - 6-1/2" 2000 psig. 6-1/2" - 8-1/2" 1500 psig. Fire Protection Hot Work Guards shall be used to confine heat sparks, and slag to protect immovable fire hazards. Examples: fire blanket, wet sacks, sand, water, steam. Normal operating procedures require periodic sampling, draining and depressuring of equipment. When such activity must be performed, all hot work activity must be stopped until area is clear of fire hazards. Fire extinguishers shall be in a state of readiness for instant use. Fire extinguishing equipment may consist of charged water hose, shovel, steam, fire fighting hand lines, fire monitors or hand portable or wheel unit fire extinguishers. Sewer cups, sewer mains, oily water run-offs will be secured to prevent ignition sources (sparks, slag, molten metal) from falling into these areas. Sparks will be confined to the welding area by means of fire blanket. Sparks should not fall from elevated welding areas. Fire Prevention for Hot Work Fire Watchers shall be required whenever hot work is being performed where a fire might develop. Training will be conducted for the fire watch upon initial job assignment and annually thereafter. Fire Watchers shall have fire extinguishing equipment readily available at all times. Fire Watchers will be instructed by the Supervisor/Chief operator issuing the permit of the potential hazards within the area of work. They will watch for fires in all exposed areas. The fire watch will extinguish fires within the capacity of the extinguishing equipment available. The fire watch will sound an alarm air horn, stopping all hot work, whenever a fire occurs. After extinguishment of any fires, the fire watch will immediately report the incident to the operator that issued the permit. For welding operations the fire watch will include in his watch area the grounding connection for the welding machine. The fire watch shall be maintained for a minimum of a half hour after completion of welding or cutting operations to detect and extinguish possible smoldering fires. At the discretion of the Supervisor/Chief Operator issuing the permit, consultation with the Safety Department may be required for additional fire protection measures. Personal Protective Equipment The Supervisor/Chief Operator will be responsible for determining the necessary personnel protective equipment and insuring its use. Proper PPE will be indicated on the permit using the appropriate box. Auditing Permit to Work Procedure Area Issuing Department Document # Approved by Revision # Date Page General Safety SSP0004 Wade Gauthreaux/Jeff Warmann 2 8/05/11 3 0f 6 Maintenance Supervisors, Operations Area and Shift Supervisors, Chief Operators and Safety Supervisory personnel shall conduct annual audits on SSP-0004 to assure the effectiveness of this policy. The Joint (Union/Company) Health and Safety Committee will conduct monthly audits of SSP-0004, Hot Work. The Chief Operator will conduct routine audits of all hot work occurring in his area to ensure the work is being executed per this policy. The Safety Department will also randomly audit hot work jobs to ensure compliance with procedures. Confined Space Permitting Below are examples of confined spaces that would require permitting. Any type of vessel, Stationary or portable tanks, Sumps or pits 4’ deep or more, external floating roofs at a depth of 4’ or more, Internal floating roofs, excavations 4’ deep or more, any lines large enough for a person to place their head into. Confined Space Hazard Assessment Hazards shall be identified for each confined space. The hazard identification process shall include, but not be limited to, a review of the following: The current uses of the confined space which may adversely affect the atmosphere of the confined space. The physical characteristics, configuration, and location of the confined space. Existing or potential hazards in the confined space, such as: Oxygen deficient or enriched atmosphere, Flammable/explosive atmosphere, Toxic atmosphere, Mechanical hazards. Hazards identified shall be evaluated by a qualified person. Each hazard shall be examined with respect to: Scope of hazard exposure - Consideration should be given to how many, or which employees, or both, are exposed or may be affected. Magnitude of the hazard - Consideration should be given to how much energy may be released; how toxic are the chemicals; quantity of materials which could be inadvertently introduced, etc. Likelihood of hazard occurrence - Consideration should be given to the range of probability for the hazard to occur, i.e., certain to impossible. Consequences of the hazard occurrence - consideration should be given to the most likely outcome if the hazard occurs, i.e., space explosion, death by asphyxiation, etc. Potential for changing conditions/activities or the introduction of hot work or cleaning agents into the confined space that were not identified in the original hazard identification and evaluation, nor accounted for on the hazard evaluation. The filling of an adjacent tank is an example of changes in an adjacent space. Weather changes, such as thunderstorms, are examples of changes in environment which can cause problems in confined spaces. The hazard introduced by tools to be used in the confined spaces should also be considered such as sparks from steel tools in a potentially explosive atmosphere. Strategies for controlling the hazards. Impact on the need for emergency response - The size and location of the manway may be such that special equipment is needed for rescue of the occupants. Equipment Preparation Confined Space Entry ISOLATION and LOCKOUT/TAGOUT: The vessel should be completely isolated from other systems and equipment. Positive measures must be taken to prevent harmful material from entering the tank while workmen are inside. Lockout/Tagout of all equipment and processes will comply with the refinery Lockout/Tagout Policy (SSP-0001). Lockout/Tagout of equipment, systems and processes shall be confirmed prior to permitting entry into the confined space. All lines to and from the vessel will be physically disconnected, or blinded at the closest flange to the vessel. Drains or overflow lines will be disconnected, blinded, or plugged, if they extend into a sewer from which steam, hydrocarbon liquid or fumes, or other product could be conducted back into the vessel. Open ends of disconnected lines will be blind-flanged or plugged to prevent accidental backflow from external sources Completeness of blinding will be physically checked by a qualified person, the blind list will be initialed by operations and maintenance. Blinds shall be meet minimum thickness requirements per ANSI flange rating standards. See chart below VENTILATION: When ventilation is used to remove atmospheric contaminants from the confined space, the space shall be ventilated until the atmosphere is within the acceptable ranges. Ventilating equipment MUST be shut down when performing atmospheric testing. CAUTION: The ventilating equipment must be designed and used such that it does not create a hazard in itself. For example, general purpose electrically-driven fans should not be used. Ventilation shall be maintained during the occupancy if there is a potential for the atmospheric conditions of the confined space deviating from the acceptable range. CLEANING/DECONTAMINATION: Confined Spaces shall be cleaned/decontaminated of hazardous materials to the extent feasible before entry. Cleaning/decontamination shall be the preferred method of reducing exposure to hazardous materials. Where this is not practical, personal protective equipment shall be selected using the appropriate MSDS to provide proper protection against the hazards which may be present . Permit to Work Procedure Area Issuing Department Document # Approved by Revision # Date Page General Safety SSP0004 Wade Gauthreaux/Jeff Warmann 2 8/05/11 3 0f 6 Confined Space Atmospheric Testing Before entry into a confined space is allowed and on an as needed basis for the duration of the entry, testing must be conducted for hazardous atmospheres by a qualified person. The testing device to be used shall be calibrated within the manufacturers specifications before use. The qualified person performing the atmospheric testing shall sign the permit and write the number of the atmospheric testing device on the permit. The atmosphere of the confined space will be considered within acceptable limits whenever the following conditions exist: 1. Oxygen - 19.5% to 22.5% 2. Flammability - Less than 10% of the LEL 3. Toxicity - Less than recognized exposure limits as designated by NIOSH. (Example: H2S, CO, Benzene or Ammonia 4. Preferred atmospheric conditions that should be striven for are as follows: Oxygen -20.8%, Flammability - 0.0% LEL Toxicity - 0ppm or 0mg/m3 Whenever testing of the atmosphere indicates that levels of oxygen, flammability, or toxicity are not within acceptable limits, entry will be prohibited until appropriate controls are implemented ensuring safe entry. Whenever the atmosphere is not within acceptable limits prior to appropriate controls being implemented, all permits and tags should be removed and an appropriate warning should be placed at the entry point. Confined Space Responsibilities Authorized Entrants Know the hazards that may be faced during entry, including information on the mode, signs or symptoms, and consequences of the exposure. Have the knowledge to use available testing and monitoring equipment, ventilation, communications equipment and all PPE required for safe entry. Communicate or alert the attendant as necessary to maintain safe working conditions via voice or airhorn. Exit a confined space in an expeditious but safe manner whenever: a. An order to evacuate is given by the attendant or the entry supervisor; b. The entrant recognizes any warning sign or symptom of exposure to a dangerous situation or condition; c. An evacuation signal is sounded. Hole Watch - Whenever confined space entry takes place an Entry-Watch will be assigned to monitor the activities taking place within the confined space and maintain a safe working environment. The Entry-Watch must be appropriately trained and able to fulfill the duties associated to the role competently, specifically they must: Maintain contact / communication with those inside the confined space at all times Continually observe those working inside the confined space, the work in progress and the surrounding area for safety concerns Alert those inside the confined space to any danger in or around the confined space and to call for assistance immediately Ensure there is an effective means of communication to raise the alarm in the event of an emergency Be aware of the correct and proper use of a fire extinguisher and other safety equipment if needed Be familiar with the permit to work and confined space entry forms and ensure that all control measures are effectively implemented Be prepared to act in the event that a person within the confined space has a safety problem Be aware of how to shutdown equipment in the event of an emergency Be aware of who is providing emergency rescue, what rescue equipment is close by, where it is and who is available to provide assistance when using it Be aware of the procedures for sounding the alarm in the event of an emergency Be aware of the communication protocol between work site and control room Ensure that all gas testing requirements have been effectively met Blind Thickness Chart Line Size 150# Flange 300# Flange 600# Flange 900# Flange 1/2" 0.25 0.25 0.25 0.25 3/4" 0.25 0.25 0.25 0.25 1" 0.25 0.25 0.25 0.25 1 1/4" 0.25 0.25 0.375 0.375 1.5" 0.25 0.25 0.375 0.375 2" 0.25 0.375 0.375 0.5 2.5" 0.25 0.375 0.375 0.5 3" 0.25 0.375 0.5 0.5 3.5" 0.375 0.375 0.5 0.625 4" 0.375 0.5 0.75 0.75 5" 0.375 0.625 0.875 0.875 6" 0.5 0.625 1 1 8" 0.5 0.875 1.375 1.375 Permit to Work Procedure Area Issuing Department Document # Approved by Revision # Date Page General Safety SSP0004 Wade Gauthreaux/Jeff Warmann 2 8/05/11 3 0f 6 10" 0.625 1 1.375 1.625 12" 0.75 1.125 1.625 1.875 14" 0.75 1.25 1.75 2.125 16" 0.875 1.5 2 2.375 18" 1 1.625 2.125 2.625 20" 1.125 1.75 2.5 2.875 24" 1.25 2 2.875 3.5