Emissions Analyzers - University of Idaho

advertisement

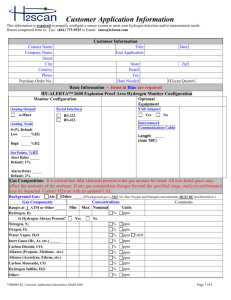

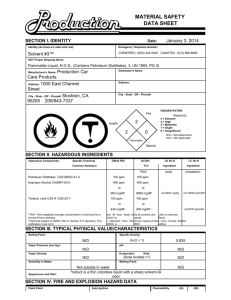

0 Measuring and Comparing Accuracy of Emissions Analyzers for Use with IC Engines (ASME IMECE2009-11295, 2009) 1.1 Abstract Automotive emission analyzers vary in price from under $1000 to well over $100,000. Different analyzers use various technologies to detect exhaust concentrations, and differ in how they condition the sample – leading to a difference in price and performance. Manufacturer claims on accuracy from less expensive analyzers are often similar to much more expensive analyzers. With a variety of analyzers available in the Small Engine Research Facility (SmERF) at the University of Idaho, this often leads to confusion in reporting accuracy of exhaust gas measurements. This study benchmarks the performance of three different analyzers: A portable 5-gas analyzer using NDIR and electrochemical cells which costs ~$5000, a portable 7-gas analyzer using separate sensors for each gas which costs ~$10,000, and a FTIR spectrometer which costs ~$100,000. High and low concentrations of single-species calibration gases (methane, carbon monoxide, carbon dioxide, nitrous oxide, hydrogen, and oxygen) were run through each machine. Initial findings showed that all species measured by the 5-gas analyzer were precise around the point of calibration, with CO and CO2 quite accurate across their whole range. The 7-gas analyzer was less accurate than the 5-gas when measuring CO, CO2, and O2, but was far more accurate for THC, NO, and NO2 measurements. The FTIR was very precise provided that water vapor was effectively removed and sample lines were adequately heated. Both of the less expensive analyzers showed reduced accuracy the further away from their calibration points. Because of high setup time, use of the FTIR should be limited to detailed emissions studies, and is not recommended for coarse tuning of an engine. 1.2 Introduction There is a large variety of technologies available for emissions sampling of engine exhaust gases. Accuracy of results depends on what type of equipment is used, and changes in ambient conditions. The intended use of the analyzer will dictate what it is designed for. Common uses for emissions analyzers are: Tuning engines, local/state emission recertification, engine research, and EPA certification. 1 Emission analyzers are found in many different price brackets. The cheapest portable multi-gas analyzers are commonly found under $5000. Portable units with improved sample conditioning and added program functionality are often found in the $5000 to $25,000 price range. Less portable units like Gas Chromatograph and Fourier Transform Infrared can cost over $100,000. And a full multi-gas rack-mount system is usually well over $100,000. Another thing to consider when selecting emissions sampling equipment is the learning curve necessary for successful operation. Some of the simpler and less expensive analyzers are almost ‘plug and play’ with no user interaction necessary. For simple units with a few options, often the user’s manual is sufficient to learn necessary procedures. The more complicated analyzers often require a day of on-site training to set up and familiarize the technician with operation of the equipment. It is not uncommon to have a large portion of an advanced degree becoming proficient with the more advanced emission analyzers. The Small Engine Research Facility (SmERF) at the University of Idaho has three different emissions analyzers: A portable 5-gas emissions analyzer, a portable 7-gas analyzer, and a Fourier Transform Infrared Spectrometer (FTIR). The goal of this research is to help select appropriate emissions sampling equipment, and to measure the accuracy of each of these analyzers over a range of gas concentrations. 1.3 Laboratory Engines The SmERF lab at the University of Idaho sees a variety of user needs for emissions sampling equipment. As part of the SAE Clean Snowmobile Challenge (CSC), testing of traditional 2-stroke engines is encountered. These engines tend to run rich air/fuel mixtures. Also, due to the consumption of lubricating oil, they often have a lot of soot/particulate/carbon in the exhaust stream. Older versions of the 2-stroke engine often have hydrocarbon (HC) emissions well over 15,000 ppm (Hexane equivalent). Other demands on the emissions equipment come from new technologies being used by the CSC team. Direct injection 2-stroke engines have promise to reduce HC emissions and improve fuel economy. Creating fuel maps for these engines is difficult because of their ability to operate in stratified-charge mode under low loads. Developing ECU maps that smoothly transition between stratified-charge and homogeneous-charge modes is especially complicated. In stratified mode 2 the global air/fuel ratio will be quite lean, but ideally a small zone of combustion will be somewhere near stoichiometric conditions. A global oxygen measurement is not sufficient to make changes to the fuel maps in the ECU. The direct injection 2-strokes produce much less soot/particulate/carbon than traditional 2-stroke engines, but this emission isn’t negligible. Research on clean/efficient gasoline 4-stroke engines may be the application many of the less expensive analyzers are best designed for. This is also the application where most emission recertification is done. Air fuel ratios are typically near stoichiometric, and emissions of carbon monoxide (CO), oxides of nitrogen (NOx), and HC are typically very low. 4-stroke diesel engines are under increasingly stricter emissions standards. Of primary concern are lowering NOx and soot/particulate emissions. However, precise measurement of CO and CO2 help estimate gross thermal efficiency. Few gas analyzers provide any soot/particulate measurement. This often requires separate sensors/equipment. Running piston engines on alternative fuels is also common in the SmERF. Some are mainstream (E85 and Bio-diesel), while others are experimental like ethanol/water blends and HCCI using JP8. In each application there are often research questions about emissions that basic analyzers cannot measure. 1.4 Laboratory Equipment The University of Idaho SmERF has three emissions analyzers that represent typical analyzers in three cost/learning curve brackets. This section describes each of the analyzers by their cost, usability/learning curve, and unique features. It also covers the type of sensor used for each gas measurement. Portable 5-Gas Emissions Analyzer This 5-gas analyzer is available with several different options. The base unit costs ~$3500 and includes sensors for: O2, CO2, CO, HC, and NOx. The unit can be upgraded to send the display values to Bluetooth compatible units where it can be monitored and recorded. Optional PC interface also allows remote display and recording of the data as well. For lower cost, a 4-gas model (no NOx measurement) is available. 3 Figure 0.1: Portable 5-gas emissions analyzer This 5-gas unit uses electrochemical sensors for the O2 and NOx measurements. Life of these sensors varies with use, but in general they last ~ 1-2 years. Error codes will flash on the display when the sensors need replacement. The other measurements for HC, CO, and CO2 are done with a NDIR cell. Calibrations are claimed to last up to a year, but periodic checking should be done with a calibration gas. Re-calibrating the unit is done using a Bar 97 gas mixture. All sensors are calibrated at once. There are few programmable parameters on the unit, which makes it very simple to operate for almost any user. Attach 12V power to the lighter-style power plug and after a short warm up period the analyzer will display current exhaust concentrations. The analyzer will turn off after it senses CO levels below 3% for more than 15 minutes. It will also perform an “auto zero” periodically when exhaust gases aren’t present. 4 The manual for the 5-gas is about 20 pages long, and easy for a non-technical audience to follow. It does not use technical jargon, and does a good job explaining the purpose and meaning behind its features – even for users not very familiar with emission sampling equipment. The optional PC software allows recording data, and information about the run. You can save vehicle descriptions and perform a few different kinds of automated tests while connected to a PC. Recorded data can be played back, but pulling the data out to a useful format (text or spreadsheet file) is not a simple task. Data can be exported to a Microsoft Access database, but it comes without column or page descriptions. Recently this 5-gas unit has been interfaced with other engine testing hardware. The serial communications port on the 5-gas can communicate with several of the more common dynamometer data acquisition systems. This allows real-time data streams from the analyzer, so recording emissions along with any other parameter from the dyno data acquisition is seamless. Table 0.1: Claimed range and accuracy of 5-gas analyzer [1] Sensor Range Accuracy 0-2000 ppm 4 ppm (Hexane equivalent) (Hexane equivalent) CO 0-10% 0.06% CO2 0-20% 0.3% O2 0-25% 0.01% 0-5000 ppm 25 ppm (Nitric Oxide) (Nitric Oxide) HC NOx Portable 7-Gas Emissions Analyzer The 7-gas analyzer was purchased to represents a high quality portable gas analyzer. It can be purchased in four different packages (kits). The kits are set up for their intended usage. The kits are: 5 Boiler, with up to 4 sensors. It includes sensors for O2 and CO. Basic, with up to 6 sensors. It includes O2, CO, NO, and NO2, and a fresh-air purge. Engine, with up to 6 sensors. It includes O2, CO (with dilution options), NO, and NO2, and a fresh-air purge. Turbine, with up to 6 sensors. It includes O2, CO, CO low, CO (with dilution options), NO low, and NO2, and a fresh-air purge. All of the units are expandable to use any six of their drop-in sensor modules. Available sensors are: O2, CO, CO low, NO, NO low, NO2, SO2, CxHy, H2S, and CO2. If more than 6 sensors are desired, multiple units can be daisy-chained together and controlled by a common handheld unit. The University of Idaho SmERF purchased a Kit #3 and added CxHy and CO2 sensors, and touch screen. This brought the price of the unit to a little over $10,000. The 7-gas analyzer uses separate sensors for each gas to be measured. Each unit can hold up to six sensors, however, the CO sensor is hydrogen compensated, and the H2 concentration can be displayed by the analyzer. This gives the possibility of recording seven different gas concentrations. The type of gas being detected determines the sensing technology used. Electrochemical sensors are used for O2, CO, NO, NO2, SO2, and H2S measurements. Each sensor is modular with all other sensors. The calibration is stored on the sensor body itself, so modules can be swapped in the field w/o the need to recalibrate. All of the electrochemical cells are continuously temperature and pressure compensated, and if a fresh-air purge is required, the sensor will be shut down before damage can occur. The CxHy sensor is of a Pellistor type. Pellistor sensors operate by catalytically burning carbon compounds, and comparing temperature on each side of the catalyst. A circuit similar to a hotwire anemometer is used to determine the temperature. Drying of the sample gas is critical because any water in the system will falsely change this temperature reading. Also, in order to burn the carbon compounds, excess oxygen must be present. For this reason, the CxHy measurement is only available when there is excess oxygen in the sample stream. The HC 6 measurement typically does not work under rich conditions – often where the most HC’s would be produced. None of the kits for this analyzer come with a CO2 sensor. Instead CO2 is calculated from the O2 measurement, and an input “Max CO2” level that is determined by the fuel type. The calculated CO2 is relatively accurate for common fuels, but is not applicable for some alternative fuels. For better accuracy, the company now sells NDIR CO2 cells that measure the CO2 in the sample stream. This option was purchased so a comparison could be made between the calculated and measured CO2 displayed by the unit. Calibration of sensors is done individually. Calibration is usually only required a few times per year, but it should be checked often with a calibration gas. Single gas mixtures (desired gas concentration in an inert dilution) can be used for calibration of individual sensors. Figure 0.2: 7-gas analyzer control unit and display 7 Because of the various setup options and programmability of the unit, it was recommended to purchase some on-site training session to help set up the analyzer for the intended usage. In this training the technician described how to navigate the menu system, and create custom programs. Initial setup time is a few hours, but once set up in a desired configuration the unit is almost ‘plug and play.’ The unit also has a battery pack that allows sampling for 2-3 hours away from a plug in power source. The manual for the 7-gas analyzer is about 60 pages long, and several supplements are offered covering topics such as calibration and software. Between these resources, there are over 100 pages of documentation. The manufacturer web site also has forums and additional downloads. Because the unit has many programmable options, there is more to discuss in the manual. The level of knowledge necessary to understand the manual is matched for those who have some experience with emissions sampling, though at a basic level. Data can be recorded in the unit, or printed on the built-in thermal printer. The optional PC based software used Microsoft Excel for the interface. Retrieving data from the software is very simple. The 7-gas analyzer has a many features not typically found on less expensive analyzers. The unit has a built-in Peltier condenser to help dry the gas before entering the unit. The programmability also allows monitoring of emissions in an automated mode. For instance, it can be programmed to take a reading once every hour, and store the data string in a single file location. This is useful for monitoring flue gases, or for long-term engine testing. The unit can measure and record deltapressure, and engine RPM. 8 Table 0.2: Claimed range and accuracy of 7-gas analyzer [2] Sensor Range Accuracy 0-44,000 ppm 400 ppm (Methane equivalent) (Methane equivalent) CO 0-10% 5 ppm (0-99ppm), then 5% m.v. CO low 0-500 ppm 2 ppm (0-35ppm), then 5% m.v. NO 0-3000 ppm 5 ppm (0-99ppm), then 5% m.v. NO low 0-300 ppm 2 ppm (0-35ppm), then 5% m.v. NO2 0-500 ppm 5 ppm (0-99ppm), then 5% m.v. 0-‘max vol %’ Calculated from O2 CO2 0-50% 0.3% plus 1% m.v. O2 0-25% 0.2% of m.v. HC CO2 (calculated) Fourier Transform Infrared Spectrometer [3] Useful for more than just emissions sampling, a FTIR spectrometer uses infrared radiation to detect compounds. For gas sampling, detection is done by absorption. The intensity vs. wavelength of a beam through inert gas (Nitrogen) is compared to that same beam going through the sample gas. The FTIR that is in the SmERF was donated by a local company. In the configuration it was delivered in, the equipment was valued at ~$150,000. Because there are not individual sensors in a FTIR, the ability to detect species concentrations depends more on the methods reference in the computer. Instead of sensors, the computer uses a spectral database of compounds. The height and frequency of peaks or valleys in the IR signature are compared to compounds in the database for matches. If the desired compound is in 9 this database, the equipment will be able to calculate the percent composition of that species in the sample [4]. Setup and use of a FTIR is not trivial. Usually a representative from the supplier will come out for a day or two to set up the equipment and train operators on how to use it. Methods for detecting desired species are usually purchased from the supplier and loaded on the computer during the on-site training. Preparing the FTIR for emission measurement takes more time than the portable analyzers. Liquid nitrogen is used to cool the sensors, and the equipment should be turned on for at least 30 minutes to allow the laser to stabilize and the test cell to reach operating temperature. Also, the system needs to be purged with a low flow of nitrogen during the whole sampling period. The large size and sensitivity of the laser and optics make the FTIR a relatively stationary piece of equipment. It can be moved around in the lab, but is not likely going to be used for any dynamic in-vehicle testing. Because of the volume of the sampling cell, the time response to changes is not as fast as some of the other analyzers. Drastic changes in composition may take a few minutes to reach their true values. Thus, the FTIR is used primarily for steady state testing. One very useful feature of the FTIR is the ability to provide hydrocarbon speciation. Where other analyzers just read an equivalent HC, the FTIR can be used to provide volume fractions of any specific hydrocarbon chain in the methods. In particular, while testing alternative fuels performing a hydrocarbon speciation is highly valuable. In the combustion of ethanol, aldehydes are formed. While not currently regulated, as ethanol-based fuels become more popular having a detailed breakdown of the HC emissions will help target appropriate after treatment systems [5]. The FTIR at the SmERF lab did not come with any sample preparation hardware. A high temperature pump is necessary to bring samples in, and filters for particulate, gas dryers, and line heaters need to be installed and maintained. A lot of plumbing and valves were added to allow quick changes from calibration, nitrogen purge, and exhaust sample inputs. The range and accuracy of gases was not provided with the FTIR. Accuracy is determined by the software and the methods programmed in the machine. A background spectrum is collected 10 before and after each sample measurement, and depending on the signal/noise ratio, the error on each gas measurement is calculated. The range depends somewhat on the length of the laser path through the sample chamber. As delivered, the SmERF FTIR had a 32 meter cell, created by bouncing the laser path 32 times across a 1 meter length cell. This proved to be far too long, as most of the exhaust gas readings were saturated and undetectable. A second side effect of the long cell was that any particulates in the exhaust sample tended to leave deposits on the optics in the cell, requiring frequent cleanings. A shorter 18 centimeter cell was built that eliminated the mirrors in the long cell. This is the longest cell that could be used in this particular FTIR with a single laser path. 1.5 Experimental Design A simple experiment has been designed to compare analyzer accuracy and precision across all three of the above mentioned analyzers. Single species calibration gases are going to be used to calibrate each sensor for CO, CO2, HC, O2, and NO2. Two concentrations, one low and one high of each species will be used. First, the high concentration will be used for calibration, and the lower will be sampled by the analyzer. The analyzer value will be compared to the known calibration. This will be repeated on 5 different occasions. Once complete, the experiment will be repeated using the low concentration for calibration, and the high concentration will be sampled using the same technique. Table 0.3: Species concentrations for single calibration gases Species Low Value High Value HC 300 ppm (CH4) 14,500 ppm (CH4) CO 100 ppm 5000 ppm CO2 0.2% 5% NO 100 ppm 2000 ppm NO2 250 ppm 2000 ppm O2 1% 15% 11 1.6 Results The first single species experiment was done by calibrating with a high concentration, then sampling a low concentration. This method should give a strong 2-point calibration, and simulate a clean or diluted exhaust mixture. In each table, the sample species and concentration are provided. The 90% confidence interval is provided in the “Precision” column. This value was calculated using the standard deviation after five separate runs of data collection, and is weighted using the t-statistic. The “Accuracy” column compares the average reading from the five replicates to the known gas concentration. If the reading was lower than the actual concentration, a negative number is in the table. The last column is the claimed accuracy by the manufacturer. Table 4 shows the results for the 5-gas analyzer, and Table 5 shows the results for the 7-gas analyzer. For the 5-gas analyzer the accuracy for the NO2 reading and CH4 are greater than was claimed by the manufacturer. In the case of NO2, it appears the sensor may not be capable of detecting that species. The unit is sold as being capable of detecting NOx, but likely it only detects NO. The O2 reading was also significantly off compared to the claimed accuracy. Also surprising is the error on the CH4 reading. The unit is supposed to provide Hexane equivalent hydrocarbons, but did not detect most of the methane sampled. The accuracy of the 7-gas analyzer was also not as good as claimed for the CO measurement. Also noticeable was the NO measurement, which had a 3x greater error than claimed. There was a slight error on the O2 accuracy, but it was not significant. 12 Table 0.4: 5-gas analyzer with high concentration calibration Sample Precision Accuracy Claim CO – [0.01%] 0.00% 0.00% 0.06% CO2 – [0.2%] 0.00% -0.10% 0.30% NO – [100 ppm] 11.31 ppm -11.57 ppm 25 ppm NO2 – [50 ppm] 1.52 ppm -46.3 ppm N/A 0.10% 0.63% 0.01% 2.1 ppm -286 ppm 4 ppm O2 – [1.0%] CH4 – [300 ppm] Table 0.5: 7-gas analyzer with high concentration calibration Sample Precision Accuracy Claim CO – [0.01%] 0.00% 0.01% 0.00% CO2 – [0.2%] 0.00% -0.23% 0.30% NO – [100 ppm] 3.266 ppm 14 ppm 5 ppm NO2 – [50 ppm] 0.598 ppm 1.84 ppm 5 ppm 0.04% 0.06% 0.00% 27.5 ppm 117 ppm 400 ppm O2 – [1.0%] CH4 – [300 ppm] The next two tables show the results of the second single species experiment. In this case the calibration was done with the low concentration values, and then the high concentration gas was sampled. Table 6 is for the 5-gas analyzer, and Table 7 is for the 7-gas. As noted previously, the 5-gas analyzer had difficulty measuring the NO2, O2, and CH4. However, for this experiment it also showed more error than claimed for the NO measurement. 13 The 7-gas analyzer had a lot of error on the NO measurement, and was slightly out of the claimed accuracy for CO2 as well. The O2 reading was quite a ways off of actual when calibrated with low concentrations. Table 0.6: 5-gas analyzer with low concentration calibration Sample Precision Accuracy Claim CO – [0.5%] 0.03% 0.02% 0.06% CO2 – [5.0%] 0.08% -0.11% 0.30% NO – [2000 ppm] 11.34 ppm -127.9 ppm 25 ppm NO2 – [250 ppm] 3.60 ppm -228.3 ppm N/A 0.10% 0.43% 0.01% 3.4 ppm -14,000 ppm 4 ppm N/A N/A N/A O2 – [15 %] CH4 – [14,500 ppm] H2 [1000 ppm] Table 0.7: 7-gas analyzer with low concentration calibration Sample Precision Accuracy Claim CO – [0.5%] 0.04% 0.02% 0.025% CO2 – [5.0%] 0.04% 0.38% 0.35% NO – [2000 ppm] 60.11 ppm 293.3 ppm 100 ppm NO2 – [250 ppm] 3.23 ppm -7.771 ppm 12.5 ppm 0.04% -0.11% 0.03% 361 ppm 55.4 ppm 400 ppm 191.8 ppm -391 ppm None Given O2 – [15 %] CH4 – [14,500 ppm] H2 [1000 ppm] 14 1.7 Conclusions The 5-gas analyzer was about 1/3 the price of the 7-gas analyzer. It proved to be highly inaccurate for NO2, and marginally accurate for NO. The O2 reading was inaccurate at low levels, and had more error than advertised. It was also poor at detecting CH4. However, the NDIR cell was more accurate at detecting CO and CO2 than the more expensive 7-gas analyzer. Another positive for the 5-gas unit are that it is very simple for students to use. From the mixed gas results, the CO/CO2 interaction seems to be a little off, but it still provides reasonable results. The 7-gas unit adds separate NO and NO2 measurements, and the ability to sense hydrogen. The NO2 measurement was consistently within the claimed accuracy, but the NO measurement was nearly 3x high in both cases. The main concern in using this as an engine analyzer is that the CO, H2, and HC measurements require excess oxygen to function correctly. It is usually the case with IC engines that CO and HC emissions are highest when the engine is operating under rich conditions. Under these conditions there will not be enough oxygen present for the analyzer to measure these species. The 7-gas unit was also equipped with a dilution system for the CO measurement. When checked with a precision flow meter, the indicated flow was off by ~75% of the measured value, as was the concentration measurement. This made the dilution feature unusable. The 7-gas unit uses a much lower sample flow rate than the 5-gas and FTIR. This allows long life of calibration gases, but also makes for slow transient response. Between changes in gas concentration there was often as long as 2 minutes before the readings reached steady state. The FTIR showed the lowest error, with the ability for hydrocarbon speciation down to a +/- .01 ppm accuracy. However, due to the time overhead and slow time response this is not the instrument of choice for tuning an engine. Rather, this is better used to make measurements once an engine is tuned with the other analyzers. 1.8 References 1. Operators manual for 5-gas analyzer 2. Operators manual for 7-gas analyzer 3. Operators manual for FTIR 4. Manning, Chris “A Brief Introduction to Fourier Transform Infrared Spectrometry.” American Chemical Society National Meeting. Washington DC, 2000 15 5. Lowry, Steven T. “Direct Comparisons of FTIR with conventional analyzers for the measurement of vehicle emissions.” Proceedings of SPIE – The International Society of Optical Engineering, v. 2365. Bellingham, WA. 1995 1.9 Appendix 1 – Modification to FTIR The Nicolet FTIR was donated to the University of Idaho by Micron Technologies. As delivered it had a 32 meter laser path. A capstone team was assigned the task of getting the machine operational as an exhaust analyzer that was capable of speciating hydrocarbons. Because of the high moisture content of exhaust gas, the 32 meter cell proved to be too long, and most of what the unit picked up was overshadowed by the water signal. In the last week of their project the capstone team acquired a shorter 7.5 cm cell and installed this in the FTIR. The shorter cell did fix the problem with signal saturation, but opened up other problems. Due to the placement of the inlet/outlet plumbing and cell pressure sensor one of the covers on the FTIR was not able to be used. The volume of the laser path should be sealed to that the cavity can be purged with nitrogen. With one of the covers missing there was a portion of the laser path that was going through ambient air. This and the short length of the cell caused the signal-to-noise ratio (SNR) of the detector to be greatly reduced. SNR was a full order of magnitude lower ( averaging around 0.00005 V peak to peak, and 0.000001 V RMS) than achieved with the original 32 meter cell. This caused the calculated error in measurement to be nearly an order of magnitude greater. Measurements of CO2 in the 5% range were seeing calculated errors in the +/2% range. To improve the error of the cell, a new 18 cm cell was built. This is the longest single-pass cell that can fit in to the FTIR. Care was taken to position the fittings such that the center cover could be used, sealing the full laser path. A new bottom mounting plate was made that used bulkhead fittings also sealed the bottom of the cell from ambient air. With these changes, the SNR was improved to original values (typically ~0.0005 V peak to peak, and 0.0001 V RMS). Calculated errors were much smaller with the new cell and sealed laser path. But when testing with various calibration gases, the measured concentration and calculated error were significantly different than the actual calibration gases. Data taken with the FTIR is shown in Table 8. The sample concentration is shown, along with the measured concentration and calculated error from 16 the FTIR. None of the measurements fall within the calculated error bounds of the actual concentration. 0.8: Data from FTIR with 18 cm cell and sealed laser path Sample Measured Value Calculated Error Actual Error CO – [100 ppm] 186.5 ppm 5 ppm 86.5 ppm CO – [5000 ppm] 12,025 ppm 598 ppm 7025 ppm CO2 – [2000 ppm] 550 ppm 1037 ppm -1450 ppm CO2 – [50,000 ppm 10,861 ppm 1188 ppm -39,139 ppm CH4 – [300 ppm] 668.14 ppm 51.2 ppm 368.14 ppm CH4 – [14,500 ppm] 32,842 ppm 1650 ppm 18,342 ppm Two bottles of calibration gas mixtures were also run through the FTIR. These results are shown in Table 9. Just as with the single species calibration gas, none of the actual concentrations fall within the measurements and error bounds. 17 Table 0.9: Calibration gas mixtures Sample Measured Value Calculated Error Actual Error Hexane – [1481 ppm] Not in methods Not in methods Not in methods CO – [40,000 ppm] 100,009 ppm 9580 ppm 60,009 ppm CO2 – [50,000 ppm] 8084 ppm 2059 ppm 41,916 ppm CO – [5000 ppm] 12,248 ppm 579 ppm -37,752 ppm CO2 – [60,000 ppm] 13,376 ppm 1669 ppm -46,624 ppm NO – [298 ppm] 600.02 ppm 24.3 ppm 302.02 ppm 3.16 ppm 3.20 ppm 3.16 ppm NO2 – [0 ppm] After the testing is complete, the cell is purged with nitrogen. Measurements were recorded once the readings reached stead state with a constant flow of nitrogen through the cell. The readings are shown in Table 10. In this case, with the exception of CO, all of the readings are within the error calculated by the instrument. However, CO2 and CO have the highest errors. This is strange because state-of-the-art equipment for measuring exhaust emissions often uses a FTIR for CO2 and CO measurement. Table 0.10: FTIR readings with nitrogen purging the cell Sample Nitrogen – [100%] Measured Value Calculated Error CO2: 480.59 CO2: 1507.9 CO: 1.859 CO: 0.470 NO: 0.1615 NO: 5.67 NO2: 0.551 NO2: 3.327 N2O: -0.381 N2O: 0.5379 CH4: -15.73 CH4: 41.613 C2H6: 0.53 C2H6: 1.175 18 Because the FTIR is not reading correctly, it should be looked at by a specialist. It is possible that someone from the Chemistry department or Manning Applied Technology would be able to recommend a solution for the errant analyzer readings. 1.10 Appendix 2 – Horiba 5-gas Analyzer The Horiba MEXA-584L is a 5-gas analyzer similar to the one covered earlier in this chapter. It also used a NDIR cell and electrochemical sensors to measure exhaust emissions of CO2, CO, HC, O2, and NO, but costs closer to $12,000 depending on features. It was purchased to represent a simple to use analyzer, with improved accuracy over the previous 5-gas analyzer. The Horiba unit operates from a 120 VAC power source, but functions as a plug-n-read type of device that is very easy for students to become comfortable using. Improved features that this unit has over the other 5-gas analyzer in the lab are a set of analog outputs. This makes the analyzer very easy to interface with other data logging devices. The system can be fed in to the dynamometer software, can be used with Labview for our dilution tunnel system, or transported with a vehicle (like the Clean Snowmobile) and recorded on a small USB analog recorder. It also has additional inputs for engine speed, and oil temperature that can be recorded. The manual for the Horiba analyzer is about 60 pages long, but a separate manual of equal size is provided specifically for the serial communication and analog output specifications. The unit has built-in diagnostics and advanced users can access higher level features and custom menus. Claimed accuracy for the analyzer is given in Table 11. The Horiba 5-gas analyzer was put through the same test procedure as the 5 and 7 gas analyzers in this chapter. Results are shown in Table 12 and 13. 19 Table 0.11: Claimed range and accuracy of the Horiba 5-gas analyzer Sensor HC CO Range Accuracy 0-60,000 ppm Within 60 ppm or 5% of reading (Methane equivalent) (whichever is larger) Within 0.03% or 3% of reading 0-10% (whichever is larger) Within 0.03% or 5% of reading (0-8%) CO2 Within 0.04% (8-15%) 0-20% Within 0.06% (15-20%) Within 0.1% or 3% of reading O2 0-25% NO 0-5000 ppm (whichever is larger) Within 25 ppm or 4% of reading (0-4000 ppm) Within 8% of reading (4000-5000 ppm) Table 0.12: Horiba 5-gas analyzer with high concentration calibration Sample Precision Accuracy Claim CO – [0.01%] 0.00% 0.01% 0.03% CO2 – [0.2%] 0.00% -0.02% 0.03% NO – [100 ppm] 2 ppm -7 ppm 22 ppm NO2 – [50 ppm] 1 ppm -49 ppm No claim to measure NO2 0% -0.03% 0.1% 2.5 ppm -210 ppm 15 ppm O2 – [1.0%] CH4 – [300 ppm] 20 Table 0.13: Horiba 5-gas analyzer with low concentration calibration Sample Precision Accuracy Claim CO – [0.5%] 0.02% 0.02% 0.03% CO2 – [5.0%] 0.02% 0.12% 0.30% NO – [2000 ppm] 3 ppm 7 ppm 80 ppm NO2 – [250 ppm] 5 ppm -218 ppm No claim to measure NO2 0% 0.32% 0.45% 3.1 ppm -11,850 ppm 725 ppm N/A N/A N/A O2 – [15 %] CH4 – [14,500 ppm] H2 [1000 ppm] Unlike the other analyzers in this chapter, the error of the Horiba seems to be within the range specified by the manufacturer. The analyzer does not claim to measure NO2, and for the most part it does not. The hydrocarbon measurement is out of spec in both instances. This is largely due to the calibration being done with hexane (C6H14), and the reported hydrocarbons on the analyzer is supposed to be in hexane equivalent (ie: methane, CH4 will read 1/6th of the actual value). This was corrected for in the data, but the analyzer still does a very poor job at detecting methane. Tests conducted with propane (C3H8) were improved, but still out of spec. Tests using Hexane were within the manufacturer specifications of error. The Horiba 5-gas analyzer should be a simple to use, accurate device for students to make exhaust emissions measurements with. The hydrocarbon measurement is not reliable enough to use for carbon-balances, but should provide an adequate comparison of HC emissions for students to use while mapping an engine computer for improved emissions. Continual use will show if this analyzer is rugged enough to put up with the abuse of student use and projects. Given its relatively low cost to individual detectors, this looks to be a fair price for an analyzer that is simple to use and has better accuracy than the other analyzers in this chapter.