Q5_cs

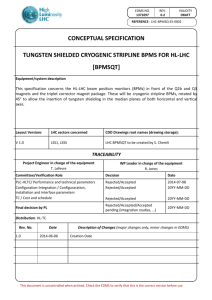

advertisement

EDMS NO. 1366544 REV. 1.0 VALIDITY DRAFT REFERENCE : LHC-EQCOD-ES-XXXX CONCEPTUAL SPECIFICATION Q5 Equipment/system description The Q5 is the quadrupole in the matching section following Q4. It must have a 70 mm aperture to allowing to reach values of β* in the IP of the order of 10 cm. The two apertures are independently powered; it replaces the present 56 mm aperture MQM, making use of the MQY used in the LHC. Layout Versions LHC sectors concerned CDD Drawings root names (drawing storage): V X.X S1-2, S4-5, S5-6, S8-1 TBD TRACEABILITY Project Engineer in charge of the equipment G. Kirby WP Leader in charge of the equipment E. Todesco, G. L. Sabbi Committee/Verification Role Decision Date PLC-HLTC/ Performance and technical parameters Configuration-Integration / Configuraration, installation and interface parameters TC / Cost and schedule Rejected/Accepted Rejected/Accepted 20YY-MM-DD 20YY-MM-DD Rejected/Accepted 20YY-MM-DD Rejected/Accepted/Accepted pending (integration studies, …) 20YY-MM-DD Final decision by PL Distribution: N. Surname (DEP/GRP) (in alphabetical order) can also include reference to committees Rev. No. X.0 Date 20YY-MM-DD Description of Changes (major changes only, minor changes in EDMS) Description of changes This document is uncontrolled when printed. Check the EDMS to verify that this is the correct version before use EDMS NO. 1366554 REV. 1.0 VALIDITY DRAFT REFERENCE : XXX-EQCOD-ES-XXXX 1 CONCEPTUAL DESCRIPTION 1.1 Scope The Q5 is the quadrupole in the matching section following Q4. It must have a 70 mm aperture to allowing to reach values of β* in the IP of the order of 10 cm. The two apertures are independently powered; it replaces the present 56 mm aperture MQM, making use of the MQY presently used in the LHC at 4.5 K. 1.2 Benefit or objective for the HL-LHC machine performance The large aperture of this magnet (70 mm) allows reaching a beta function in the IP of the order of 10 cm. 1.3 Equipment performance objectives This magnets will provide an integrated gradient of 680 Tm, with 200 T/m in the transverse plane and a 3.4 m lenght, with operational temperature of 1.9 K. Page 2 of 6 Template EDMS No.: 1311290 EDMS NO. 1366554 REV. 1.0 VALIDITY DRAFT REFERENCE : XXX-EQCOD-ES-XXXX TECHNICAL ANNEXES 2 PRELIMINARY TECHNICAL PARAMETERS 2.1 Equipment Technical parameters Table 1: Equipment parameters Characteristics Aperture Number of apertures Distance between apertures at 1.9 K Cold mass outer diameter Shell thickness Integrated gradient Magnetic length Gradient Peak field Current Temperature Loadline margin Overall current density Stored energy per meter (two apertures) Differential inductance per meter Stored energy (two apertures) Differential inductance Superconductor Strand diameter Cu/No Cu RRR strand / RRR cable Superconductor current density at 9 T, 1.9 K Number of strands per cable Cable bare width Cable bare mid thickness Keystone angle Insulation type Insulation thickness radial Insulation thickness azimuthal Number of layers Number of turns Cable unit length (one pole) Coil physical length Magnet physical length Cold mass weigth Heat exchanger hole diameter Heat exchanger angle Page 3 of 6 Units mm mm mm T m T/m T kA K (%) A/mm2 MJ/m mH/m MJ mH mm A/mm2 mm mm degrees mm mm m m m t mm degrees Value 70 2 194 495 10 680 3.4 120 7.6 4.5 1.9 20 370/530 0.440 22 1.5 75 Nb-Ti 0.735/0.475 1.25/1.75 >150 / >70 1990 22/34 8.3/8.3 1.285/0.845 2.16/1.05 0.080 0.075/0.080 4 74=16+21+17+20 160/380 3.6 3.8 7 60 90 Template EDMS No.: 1311290 EDMS NO. 1366554 REV. 1.0 VALIDITY DRAFT REFERENCE : XXX-EQCOD-ES-XXXX Heat exchanger distance from centre Fx (per octant) Fy (per octant) Fz (whole magnet) Stress on the mid-plane Cold bore thickness Gap cold bore to coil Fringe field on the cryostat outer surface mm MN/m MN/m MN MNP mm mm mT 95 We reuse the present MQY, lowering the operational temperature from 4.5 to 1.9 K and increasing the operational gradient from 160 T/m to 200 T/m. The work will consist in adapting the present cold mass for 1.9 K operation, and possibly designing and building the new cryostat. 2.2 Operational parameters and conditions They will operate under a peak heat load due to the debris shower of 0.8 mW/cm3, 20 MGy of radiation dose, and will need a cooling power of 10 W (7 W at nominal plus 50% margin). 2.3 Technical and Installation services required Table 2: Technical services Domain Electricity & Power Cooling & Ventilation Cryogenics Control and alarms Vacuum Instrumentation Requirement 6 kA circuit 1.9 K cooling through heat exchangers 10 W cooling power per magnet (7 W operational plus 50% margin) Voltage taps for quench detection Table 3: Installation services Domain Civil Engineering Handling Alignment 2.4 2.5 Requirement Cold mass alignment in the cryostat within 0.1 mm (TBC) and 1 mrad (TBC) P & I Diagrams Reliability, availability, maintainability If the magnet is not providing the integrated field, the nominal optics cannot be provided. Failure of the magnet could be bypassed by special optics with significant performance loss. Lower gradient will correspond to lower collision energy. A lower than specified cooling power can limit the peak luminosity to values lower than nominal. A lower than specified radiation resistance can break the magnet before the gathering 3000 fb-1 in HL-LHC. 2.6 Radiation resistance The equipment is designed to withstand 25 MGy. Page 4 of 6 Template EDMS No.: 1311290 EDMS NO. 1366554 REV. 1.0 VALIDITY DRAFT REFERENCE : XXX-EQCOD-ES-XXXX 2.7 List of units to be installed and spares policy 4 cold masses to be installed, 2 per side at IP1 and IP5. Spare cold masses already available. 3 PRELIMINARY CONFIGURATION AND INSTALLATION CONSTRAINTS 3.1 Longitudinal range From 175.8 m to 179.6 m from the IP. 3.2 Volume 495 mm diameter and 3.4 m length: 0.65 m3. 3.3 Installation/Dismantling The zone D2-Q4-Q5 needs to be dismanteled. 4 PRELIMINARY INTERFACE PARAMETERS 4.1 4.2 Interfaces with equipment Electrical interfaces Table 4: Circuits to be generated New circuit description RQ5.B1L1 RQ5.B2L1 RQ5.B1R1 RQ5.B2R1 RQ5.B1L5 RQ5.B2L5 RQ5.B1R5 RQ5.B2L5 5 COST & SCHEDULE 5.1 Cost evaluation Circuit LHC code name (if known) Approx. current rating (if known) Approx. voltage rating (if known) 6 kA 6 kA 6 kA 6 kA 6 kA 6 kA 6 kA 6 kA Project code 91111 Page 5 of 6 Template EDMS No.: 1311290 EDMS NO. 1366554 REV. 1.0 VALIDITY DRAFT REFERENCE : XXX-EQCOD-ES-XXXX 5.2 Conceptual schedule Table 5: Conceptual schedule Phase 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 Test at 1.9 K Engineering design of cold mass modifications and cryostat Assembly of five units Test Installation 6 TECHNICAL REFERENCE DOCUMENTS Future magnet report 7 APPROVAL PROCESS COMMENTS FOR VERSION X.0 OF THE CONCEPTUAL SPECIFICATION 7.1 PLC-HLTC / Performance and technical parameters Verification Comments or references to approval notes. In case of rejection detailed reasoning 7.2 Configuration-Integration / Configuraration, installation and interface parameters Verification Comments or references to approval notes. In case of rejection detailed reasoning 7.3 TC / Cost and schedule Verification Comments or references to approval notes. In case of rejection detailed reasoning 7.4 Final decision by PL Comments or references to approval notes. In case of rejection detailed reasoning Page 6 of 6 Template EDMS No.: 1311290