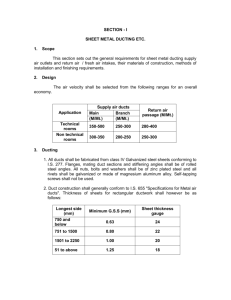

BOQ for Replacement of Old Ducts with New Ducts

advertisement

3.0 JOB # 2: FABRICATION OF NEW DUCTS – BOQ FOR REPLACEMENT OF OLD DUCTS WITH NEW DUCTS: S.No. Description Qty (nos/lot) 3.1 Basement Supply Air Ducts: 3.1.1 Dismantling, removing and disposing off of existing wooden ducts complete along with its supply air grilles, dampers and insulation. One lot 3.1.2 Supply, Fabrication, Installation with supports, testing and commissioning of sheet metal ducts GSS ducting as per IS 655 std.-SAIL/Bhushan/Jindal. 125 M2 The duct has to be connected to the existing three supply air ducts (those are coming from AHU to this floor) Rate (Rs.) Total Amount (Rs.) (85 M2 22 gauge and 40 M2 24 gauge) Air to be distributed 6,000 CFM in a rectangular ring form. Air velocity in supply ducts to be maintained preferably within 1200 FPM. 3.1.3 Supply, Installation, Testing of GS construction Louver dampers within ducts to be provided with suitable ducts lever and quadrants for manual control of volume of air flow and for proper balancing of the air distribution system. Dampers: Caryaire/Opella or equivalent. 0.8 M2 3.1.4 Supply, Installation, Testing and balancing of powder coated Extruded Aluminum supply air registers (grilles with volume control dampers). Grilles should have adjustable double louvers. 2.5 M2 Total number of registers about 25 Out air velocity at supply grilles 500 –750 FPM. Grilles: Caryaire/Opella or equivalent. 1 S.No. Description Qty (nos/lot) 3.1.5 Supply and Installation of external thermal insulation of 19 mm thickness with aluminum cladding on supply air ducts (Microcellular Closed Cell Nitrile Rubber Insulation. Thermal Conductivity 125 M2 Rate (Rs.) Total Amount (Rs.) 0.038 W/m Deg K, 60 kg/m3 density). Insulation: K flex or equivalent. 3.2 First Floor Supply Air Ducts: 3.2.1 Dismantling, removing and disposing off of existing wooden ducts complete along with its supply air grilles, dampers and insulation. Supply, Fabrication, Installation with supports, testing and commissioning of sheet metal ducts GSS ducting as per IS 655 std.-SAIL/Bhushan. 3.2.2 The duct has to be connected to the existing three supply air ducts (those are coming from AHU to this floor) One lot 180 M2 (125 M2 22 gauge and 55 M2 24 gauge) Air to be distributed 10,500 CFM in a rectangular ring form. Air velocity in supply ducts to be maintained preferably within 1200 FPM. 3.2.3 Supply, Installation, Testing of GS construction Louver dampers within ducts to be provided with suitable ducts lever and quadrants for manual control of volume of air flow and for proper balancing of the air distribution system. Dampers: equivalent. 3.2.4 Caryaire/Opella 1.0 M2 or Supply, Installation, Testing and balancing of powder coated Extruded Aluminum supply air registers (grilles with volume control dampers). Grilles should have adjustable double louvers. 3.5 M2 Total number of registers about 30 2 S.No. Description Qty (nos/lot) Rate (Rs.) Total Amount (Rs.) Out air velocity at supply grilles 500 –750 FPM. Grilles: Caryaire/Opella or equivalent. 3.2.5 Supply and Installation of external thermal insulation of 19 mm thickness with aluminum cladding on supply air ducts (Microcellular Closed Cell Nitrile Rubber Insulation. Thermal Conductivity 180 M2 0.038 W/m Deg K, 60 kg/m3 density). Insulation: K flex or equivalent. 3