Digest example

advertisement

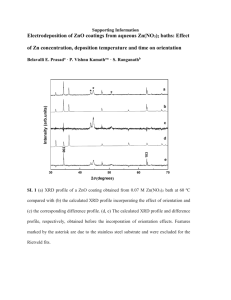

C4 WRITABILITY IMPROVEMENT IN PERPENDICULAR RECORDING MEDIA USING CRYSTALLINE SOFT UNDERLAYERS S.N. PIRAMANAYAGAM, Binni VARGHESE, Hang Khume TAN, Yu Yu Ko HNIN, Wee Kiat LEE Data Storage Institute, Singapore Iwao OKAMOTO, Lianjun WU, and Debashish TRIPATHY Western Digital Corporation, Singapore I. INTRODUCTION Perpendicular Magnetic Recording (PMR) has been in practical use for the past 6 years. The recording areal density has increased at an annual growth rate of over 30% and has reached a value of about 600 Gbpsi in latest generation drives. It is widely believed that the growth rate of magnetic recording may be reduced if alternative technologies or methods are not introduced. One of the major challenges associated with PMR is the writability. If the media grain size has to be shrunk to increase the signal-to-noise ratio (SNR), the anisotropy constant of the medium has to be increased. This poses a limitation in the writability. The invention of media structures such as exchange coupled composite (ECC) or exchange-spring media [1,2] where an exchange-break layer or two is inserted between grains of high Ku and lower Ku has helped in solving the writability issues so far. While those designs are still being fine-tuned, shingled writing has been considered as a possible technique to improve writability further. One aspect that has not yet been given a serious consideration in improving the writability is the use of crystalline soft underlayers (C-SUL) [3]. Media designs that help to reduce the spacing between the head and the soft underlayers (SUL) or the head-keeper spacing, (HKS) are of potential use in improving writability further. These structures, however, have not been well investigated. In this talk, we will discuss various media configurations by incorporating a C-SUL and will present our major findings in terms of microstructure and writability improvement. II. EXPERIMENTAL DETAILS All the samples in the present study were fabricated by dc magnetron sputtering at room temperature, using Intevac Lean 200 (Gen II) sputtering machine. Crystalline soft underlayers of different compositions were used in the media designs, in order to study the dependence on the saturation flux density. The thin film samples were characterized by polar Kerr magnetometry (MOKE), X-Ray Diffraction (XRD) and atomic force microscopy. A Guzik spin-stand was used to characterize the read-write performance. III. RESULTS Figure 1 shows a schematic diagram of various media structures. The reference medium comprises amorphous SUL, Ru seedlayers and a recording layer. A capping layer was used to control the exchange coupling and to minimize the switching field distribution. Figure 1 also shows the hysteresis loop for the reference media structure with the a-SUL. The coercivity (Hc) and nucleation field (Hn) are about 5000 Oe and 2000 Oe respectively. The media with C-SUL were also optimized to achieve similar values of Hc and Hn, in order to compare the improvement in writability in a fair manner. Figure 2 shows XRD patterns of the reference media, media1 with C-SUL and media 2 with C-SUL. XRD studies revealed that media with C-SUL have good crystallographic texture, which is comparable or better than the reference media using a-SUL. Overwrite improvement by about 6 dB were observed in well-designed samples. Roughness of the samples were higher when the thickness of the C-SUL was higher, optimization of which is a challenge. The talk will cover the magnetic, microstructure investigations and compare it with the recording performance. REFERENCES 1) R.H. Victora and X. Shen, IEEE Transactions on Magnetics, 41, NO. 2, 537-542, (2005). 2) D. Suess et al., J. Magn. Magn. Mat, 551, 290-291, (2005). 3) S.N. Piramanayagam, et al., J. Magn. Magn. Mat, 303, 287-291, (2006). S.N. Piramanayagam Data Storage Institute A*STAR (Agency for Science Technology and Research) 5, Engineering Drive 1 Singapore - 117608 Tel: +65-6874-8550 e-mail: prem@ieee.org C4 Fig. 1 Schematic diagram of media designs with crystalline SUL structure. Intensity (a.u.) Reference media Media 1 with C-SUL Media 2 with C-SUL 40 41 42 43 44 2 theta Figure 2. XRD patterns of media with and without C-SUL 45 46