Preliminary-Study-of-Purified-Glycerol-Palm-Oil-as-WBM

advertisement

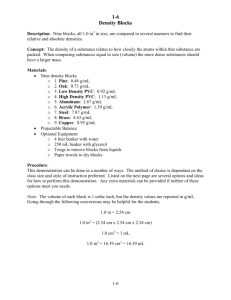

Preliminary Study of Purified Glycerol Palm Oil as WBM Lubricant and Base Fluid SBM Marbun, B. T. H.*, Aristya, R., Hutapea, P. A., Purba, N. R., Sisminardi Y. S. Institut Teknologi Bandung, Bandung, West Java, Indonesia bonar.marbun@tm.itb.ac.id, ramadhana.aristya@yahoo.com, philiphutapea@ymail.com, nikopratamapurba@hotmail.com, yogasaktyanto@gmail.com Abstract: The application of glycerol by-product of palm oil biodiesel industry in drilling fluid was carried out in this work. Glycerol will be utilized as a new alternative base fluid for Synthetic-Based Mud (SBM) and lubricant for Water-Based Mud (WBM). Due to the poor quality of crude glycerol from palm oil biodiesel industry, it needs to be purified before its physio-chemical characterizations can be tested and formulated further. An invert emulsion mud then developed using glycerol as base oil to study the emulsion stability, rheological properties, and the effect of thermal conditioning to evaluate its suitability for oil well drilling. The effect of glycerol as a lubricant additive in WBM on the mud lubrication properties, rheology, filtration loss, and its compatibility with other additives is also evaluated. The preliminary tests result indicates that glycerol can be used as SBM in accordance with the API standard and also can become the reference for this SBM development and also has been proved to increase mud lubricating potential without affecting other properties of drilling fluid significantly which is very potential due to its environmentally friendly characteristics and low cost, since it may be obtained from an abundant raw material from by-product of biodiesel production. Keyword: Glycerol, synthetic-based mud, water-based mud 1. Introduction Along with the increased productivity of biodiesel, the glycerol produced is also increasing. Glycerol is by-product of transesterification process of vegetable oil to produce biodiesel. The average amount of crude glycerol produced from biodiesel production process is about 10% [1]. Lower prices and increased production quantities will cause glycerol be not worth selling, giving rise to environmental problems caused by glycerol waste. In this study, glycerol was applied in the oil and gas industry as a drilling fluid. Due to its biodegradable and lubricating nature, glycerol could be an alternative environmentally friendly base fluid compared to diesel and common mineral oil, and also lubricant for WBM. Glycerol used in this study is derived from palm oil biodiesel production. However, purification process of poor quality crude glycerol from biodiesel making process is necessary before its physio-chemical characterization can be tested and then formulated further as base fluid for SBM and lubricant for WBM. Glycerol (glycerine, glycyl alcohol, or 1, 2, 3- propanatriol) is a substance with three hydroxyl group with characteristic of high viscosity, odorless, colorless, sweet flavoured (0.6 times sucrose), and non-toxic material in its pure condition. Glycerol has three hydroxil groups that are responsible for its solubility in water. Its hygroscopic 2 nature makes glycerol absorb water from the air. Glycerol molecular formula is C3H8O3 with molecular weight of 92. Figure 1 Glycerol Molecular Structure Table 1 Physio-Chemical Properties of Glycerol [2] PROPERTY Physical form Purity Melting point Boiling point Relative density Vapour pressure n-octanol -water partition coefficient Water solubility Dissociation constant Flash point Autoflammibility Viscosity Surface tension VALUE Liquid 95 - 99.5% (water as an impurity with trace levels polyglycerol) 18 deg C 290 deg C at 1013 hPa 1.26 at 20 deg C 0.000106 hPa at 25 deg C (calculated) and 0.0033 hPa at 50 deg C (measured) log Kow -1.76 Miscible 0.07E-13 160 deg C 393 deg C 1410 mPa.s at 20 deg C 63.4 mN/m at 20 deg C Commonly, glycerol production from fats can be done through three methods, which are saponification, hydrolisis, and transesterification. The transesterification of tryglycerides with methanol is the current route to biodiesel production, generating fatty acid methyl esters (biofuel) and glycerol. It can be estimated that from biodiesel making process, around 10% of crude glycerol are produced [3]. This crude glycerol still contains residual methanol, catalyst, and other compounds from vegetable oil as raw material of biodiesel. 3 Figure 2 Crude Glycerol from Biodiesel Making Process As a by-product of biodiesel industry, glycerol has not been widely processed so the resale value is low. Glycerol market sector for each year continues to increase followed by predictions of demand growth of biodiesel that produces glycerol as a by-product. In recent years biodiesel industry is growing rapidly due to the depletion of fossil fuels availability. Therefore, the world looking for alternative energy sources, one of which is biodiesel. This condition causes the increase of global biodiesel production. In 2006, U.S. biodiesel production reached 30-40 million gallons. If assumed, an increase in the production of 50-80% per year, then in 2012 U.S. biodiesel production will reach 400 million gallons. Glycerol abundance due to increased production of biodiesel will cause world crude glycerol prices to drop dramatically, even reaching the lowest level of prices up to $ 0.05 per lb[1]. According to Tyson (2003) [4], an increase in biodiesel production could increase production by 114% glycerol. This production increase must be accompanied by expansion of the glycerol market. 2. Methods 2.1. Crude Glycerol as By-Product of Palm Oil Biodiesel Industry In this study, crude glycerol that will be used derived from palm oil transesterification reaction. Transesterification is the process of exchanging the organic group R" of an ester with the organic group R' of an alcohol. Usually these reactions are catalyzed by the addition of an acid or base catalyst. Chemical reaction of vegeteable oil transesterification is shown in Figure 3. Triglycerides contained in palm oil are reacted with an alcohol using alkaline catalyst to produce fatty acid alkyl esters and glycerol. In this process, methanol is added as much as 15% (v/v) and mixed with KOH as much as 1% (v/v) of the total raw material olein / stearin oil to be processed to form methoxide solution. Then olein/stearin oil and mixed with a solution of methoxide transesterification reactor. Transesterification process lasted for 1 hour, stirring at a temperature of 550 C with 100 rpm. Settling process is then performed to separate the crude methyl ester and glycerol produced. 4 Figure 3 Reaction of Tryglicerides Transesterification [3] Figure 4 Flow Diagram of the Process of Making Biodiesel [5] Figure 5 Layer Formed on Transesterification Process of Triglycerides [5] 5 2.2. Purification of Crude Glycerol Crude glycerol obtained directly from the separation of biodiesel is still contains many impurities. Common compunds that cause impurities in crude glycerol are unreacted methanol, soaps, and potassium hydroxide (KOH) catalyst [6] [7]. Methanol is one of the reactants of the two main reactants in biodiesel production. Like an ordinary chemical reaction, the efficiency of its use is not 100% so that in the end there is still a residual unreacted methanol. Therefore the purification process is necessary to reduce other useless chemicals. Impurities in glycerol, especially matter organic non-glycerol (MONG), impact on the quality and quantity of glycerol generated. If level of MONG is high (3-5%) problem of odor, colour, and flavor will arise in the resulting product. Trimethylene glycol which includes MONG can affect the color of glycerol and cause problems during storage [8]. Separation of impurities from glycerol can be done with addition of phosphoric acid [6]. The acid (Figure 7) will react with residual catalyst Potassium Hydroxide (KOH) to form Potassium Phosphate salts (K3PO4). In addition, phosphoric acid will convert soaps to form free fatty acids. Expected glycerol purity obtained from this method of purification is 82.15% [5]. Figure 6 (A) Phosporic Acid Reaction with Residual Catalyst Potassium Hydroxide (B) Phosporic Acid Reaction with Soap [5] Figure 7 (A) Phosphoric Acid (B) 85% Phosphoric Acid Solution 6 Figure 8 Flow Diagram of Crude Glycerol Purification 2.3. Glycerol as Base Fluid for Synthetic-Based Mud The fluid which would be used as base-fluid for development of SBM should be analyzed first to determine its physio-chemical properties. By knowing these parameters, an early description of mud composition and behavior could be estimated. Parameters that should be tested are: a) Specific Gravity : shows the weight of base-fluid. This will indicates the density of developed mud. b) Pour Point : shows the lowest temperature at which the base-fluid still able to flow. c) Flash Point : shows the temperature at which the fluid begins to burn. d) Kinematic Viscosity : shows the resistance of base fluid to flow under the influence gravity force. Some researches have been conducted by other researchers in order to determine these base fluid properties. Table 2 shows the comparison of glycerol, palm oil biodiesel, and some mineral oils properties. 7 Table 2 Comparison of Glycerol Physical Properties With Some Base Oils Parameter Unit Crude Glycerol (Hutapea, 2013) SG Cloud Point Celcius Pour Point Celcius Flash Point Celcius 1.09 24.4 4.4 82 Kinematic Viscosity N/A cSt Glycerol After Palm Oil Purficati Biodiesel on (Hutapea, (Hutapea, 2013) 2013) 1.24 0.9 <0 21.4 <0 5.9 99 250 N/A Saraline (Setya wan et al, 2007) [9] Sarapar (Setya wan et al, 2007) [9] 0.78 N/A -16 81 0.76 N/A -11 112 3.3 2.5 5 2.3.1. Additives Selection Preliminary formulations of glycerol with certain additives were conducted in this study. The following additives were selected for the developed glycerol synthetic-based mud: primary emulsifier, secondary emulsifier, filtration control additive, viscosifier, lime, and potassium chloride. For comparison, a mineral oil and palm oil biodiesel were also formulated as base fluid using same spesification of additives. Mud formulation is shown in Table 3. Table 3 Mud Composition of Glycerol, Palm Oil Biodiesel, and Saraline SBM Mud Components Glycerol Palm Oil Biodiesel Saraline Base Fluid (ml) Primary Emulsifier (ml) Secondary Emulsifier (ml) Duratone (ppb) Lime (ppb) KCl (ppb) Water (ml) Geltone (ppb) 273 3 2 4 5 17 70 6 273 3 2 4 5 17 70 6 273 3 2 4 5 17 70 6 Mixing Duration (min) 5 5 5 5 5 10 10 10 2.4. Glycerol as Lubricant for Water-Based Mud Standard water based mud was formulated using bentonite as reactive clay. Glycerol then added as additive with various concentrations. Test parameters include: lubricity testing, plastic viscosity, yield point, gel strength, density, filtration test, and acidity of mud filtrate. 8 3. RESULTS AND ANALYSIS 3.1. Glycerol Purification Results Crude glycerol is mixed with 85% Phosphoric Acid (H3PO4) solution as much as 5% (v/v). Solution then stirred using a stirrer for about 30 minutes. Solution formed settling for 60 minutes to form three layers: a) The bottom layer is a solid form of potassium phosphate salts (K3PO4) b) The middle layer is glycerol (liquid) c) The top layer is the residual of the free fatty acid (solid under room temperature) Separation of glycerol, phosphate salts (K3PO4), and free fatty acid (FFA) is done by using decantation and filtering method with funnel 200 mesh. In the screening process, the top layer (FFA) and bottom (salt) simply left in a beaker, then the middle layer (glycerol) is filtered. To make sure the salt is left behind in glycerol filtering process, filtering is carried out using a filter press apparatus with pressure of about 30-50 psi. This method differs from previous methods from Farobie (2009), wherein the method using a burchner funnel to separate glycerol and FFA from phosphate salts first and then followed by separation of glycerol from FFA using separating funnel. The bottom layer then taken as pure glycerol.Residual photassium salt can be used as a fertilizer but still requires a process of crystallization. Figure 9 (A) Crude Glycerol and Phosphoric Acid Solution after 30 minutes Stirring (B) After 60 Minutes Settling Figure 10 (A) Residual Free Fatty Acids (B) Potassium Phosphate Salt 9 (A) (B) Figure 11 (A) Crude Glycerol (B) Purified Glycerol 3.2. Glycerol as Base Fluid for Synthetic-Based Mud Figure 12 shows viscous charateristics of crude glycerol, glycerol, palm oil biodiesel, and saraline. It can be seen that crude glycerol has very high dial reading compared to other base fluids. The 200, 300, and 600 rpm reading went off scale when the fluids are being tested. After purification process, glycerol shows better rheological properties than before. However, the viscosity of purified glycerol still several times higher compared to palm oil biodiesel and saraline. This would indicate the high viscosity of formulated mud using glycerol as base fluid. A synthetic-based mud then developed using glycerol, biodiesel, and saraline as base fluid and rheological test was conducted before thermal aging and after 20 hours thermal aging at 302 o F. Table 4 summarizes all rheological test results of the formulated muds. 300 Saraline Palm Oil Biodiesel Crude Glycerol Glycerol 250 Dial Reading 200 150 100 50 0 0 100 200 300 400 500 600 700 Rotational Speed (rpm) Figure 12. Viscosity Characteristics of Saraline, Crude Glycerol, Glycerol, and Palm Oil Biodiesel 10 Table 4 Rheological Test Results of Glycerol, Saraline, and Palm Oil Biodiesel SBM (BHR: Before Hot Rolling; AHR: After Hot Rolling) Parameters 600 rpm 300 rpm 200 rpm 100 rpm 6 rpm 3 rpm 10 sec, lb/100sqft 10 min, lb/100sqft PV, cp YP, lb/100sqft Glycerol BHR AHR 42 25 24 20 16 17 9 10 2 5 2 3 Saraline BHR AHR 22 13 13 9 10 6.5 6 4.5 2 2 2 1.5 Biodiesel BHR AHR 51 34.5 29 22 21 17 13 10 3 2.5 3 2 2 8 3 2 4 1 4 18 6 11 5 15 4 9 4 2.5 4 5 5 22 7 2 12.5 9.5 3.2.1. Before Hot-Rolling Figure 13 and 15 shows viscosity characteristics and gel strength of glycerol, biodiesel, and saraline based mud before thermal aging. As expected before, SBM glycerol has higher viscosity than the one formulated using saraline. Interestingly, formulated glycerol SBM has much lower viscosity than glycerol itself. This can happen because the reaction of glycerol with water at the mixing process. Glycerol is highly soluble in water by forming hydrogen bond with water molecules. This solubility can cause the viscosity of glycerol decreases significantly. However, the viscosity of glycerol SBM still higher than saraline SBM. Gel strengths formed by glycerol SBM have the lowest value compared to saraline and biodiesel SBM. This is indicating poor suspension capacity of the mud that would lead to hole cleaning problem during drilling. 3.2.2. After Hot-Rolling Figure 14 and 16 shows viscosity characteristics and gel strengths of glycerol, saraline, and palm oil biodiesel SBM after thermal degradation using hot-rolling oven at 302 F for 20 hours. The results show decrease of plastic viscosity from 18 cp to 5 cp followed by increase of yield point from 6 to 15 lb/100ft2 and increase in low-shear viscosity. Gel strength formed by glycerol SBM after thermal degradation is significantly increase and several times higher than saraline and biodiesel SBM, but still in acceptable range. This means at high temperature glycerol SBM will have better cutting suspension capacity with good shear thinning rheological profile (as shown in Figure 14). However, the increase in gel strength would lead to high circulation breakdwon pressure. Those results indicating that glycerol could be used as environmentally friendly base fluid for Synthetic Based Mud, but further research should be conducted to determine the correct amount of water: glycerol ratio and viscosity modifier additives to obtain the optimum rheological properties of the mud. Glycerol also cannot be treated as common 11 base fluid such as mineral oil and diesel because it cannot form an invert emulsion due to its solubility nature with water. It is more proper to treat glycerol as base fluid for Water-Based Mud with proper water: glycerol ratio, using water as media to carry additives and clay while glycerol can be a lubricating and shale stabilzer agent of the mud. The other way to utilize glycerol as base fluid for SBM is by processing glycerol with some kinds of fatty acid to produce glycerol ester of fatty acid, since it will give glycerol an oil-like nature (insoluble in water) due to its “hydrophobic” fatty acid tail in order to form invert emulsion mud with water. Figure 13 Viscosity Characteristics of Glycerol, Saraline, and Biodiesel SBM Before Hot Rolling Figure 14 Viscosity Characteristics of Glycerol, Saraline, and Biodiesel SBM After Hot Rolling (302 F, 20 hours) 12 12 11 10 9 8 7 6 5 4 3 2 1 0 10 Seconds Gel Strength Glycerol Saraline 10 Minutes Gel Strength Biodiesel Figure 15 Gel Strength of Glycerol, Saraline, and Biodiesel SBM Before Hot Rolling 12 11 10 9 8 7 6 5 4 3 2 1 0 10 Seconds Gel Strength Glycerol Saraline 10 Minutes Gel Strength Biodiesel Figure 16 Gel Strength of Glycerol, Saraline, and Biodiesel SBM After Hot Rolling (302 F, 20 hours) 3.3. Glycerol as Lubricant Additive for Water-Based Mud WBM that have been mixed with various concentrations of glycerol were tested in laboratory to determine its rheological properties, lubricity, density, filtration loss, and filtrate acidity. Table 5 shows the complete test results of the mud. 13 Table 5 Test Results of Water-Based Mud with Various Glycerol Concentrations Parameters Glycerol Concentration (%) Lubricity Test Film Strength (psi) Rheology 600 rpm 300 rpm 200 rpm 100 rpm 3 rpm 10 sec, lb/100sqft 10 min, lb/100sqft PV, cp YP, lb/100sqft LPLT Test API Filtrate, ml Filtrate pH Mudcake Thickness, cm Density, ppg 1 0 2 2 2118 2492 51 34 27 17 3 3 19 17 17 11.8 7.5 0.19 8.55 Test 3 5 4 10 5 15 4707 6051 7060 39 26 20 13 3 4 14 13 13 40 29 24 15 3 4 21 11 18 36 25 20 14 5 5 23 11 14 42 27 22 16 7 8 24 15 12 12 7 0.143 8.4 9.2 7 0.097 8.2 10.8 6 0.092 8.1 12 5.5 0.107 7.7 3.3.1. Lubricity Lubricity test using Baroid EP/Lubricity tester Model 212 was conducted on formulated WBM using glycerol as additive. Due to the limitations on the equipment, lubricating potential of glyccerol as additive will no be determined by CoF (Coefficient of Friction) of the developed WBM, but by determining film strength formed by the mud at extreme pressure (EP). The EP tests are performed by applying a measured force with a torque arm to a torque sensitive rotating bearing cup. This provides a means of testing lubrication under extreme pressure conditions and produces an indication of the film strength of the fluid being tested (Model 212 EP/Lubricity Tester Instruction Manual). Equipment procedures for lubricity test and calculations for film strength determination are attached in Appendixes. It can be seen that WBM with glycerol at various concentrations have higher film strength compared to standard WBM (0% glycerol concentration). As shown in Figure 17, the increase of mud film strength value is along with increase in the number concentration of glycerol in the mud. With maximum glycerol concentration (15 %), strength of film formed by the mud as a function of its lubrication properties has a value up to 14,000 psi. This indicates that with appropriate amount, purified glycerol by product of palm oil biodiesel process would be an effective additive to increase mud lubricity on Water-Based Mud system. 14 16000 Film Strength Film Strength (psi) 14000 12000 10000 8000 6000 4000 2000 0 0% 2% 5% 10% 15% Glycerol Concentration Figure 17 WBM Film Strength with Various Glycerol Concentrations 3.3.2. Rheological Properties Table 5 shows that glycerol existences in WBM system tend to change the viscosity characteristics of the mud. Plastic viscosity and yield point is decreased along with the addition of glycerol. Dial reading of WBM with various concentrations of glycerol, as seen in Figure 18, is slightly lower than standard WBM at same rotational speed. However, the increase of glycerol concentration in the mud will also increase both its 10 seconds and 10 minutes gel strength value (shown in Figure 19). These results shows that with utilization of glycerol as additive should be followed with addition of viscosity modifier to maintain desired rheological properties of the mud according to drilling program. Thus, glycerol-WBM system should be tested to see its suitability with other additives. 80 Dial Reading 60 0% Glycerol 2% Glycerol 10% Glycerol 15% Glycerol 5% GLycerol 40 20 0 0 100 200 300 400 500 Rotational Speed (rpm) 600 700 Figure 18 Viscosity Characteristics of WBM with Various Glycerol Concentration 15 Gels Strength (lb/100 sqft) 28 24 10 Seconds Gel Strength 10 Minutes Gel Strength 20 16 12 8 4 0 0% 2% 5% 10% 15% Glycerol Concentration Figure 19 Gel Strength of WBM with Various Glycerol Concentrations XCD Polymer (Xanthan Gum) as viscosity modifier is added to WBM with 5% glycerol concentration. Figure 20 show that polymer were dissolved and works well in glycerolWBM system to increase the desired viscosifying properties. Dial reading of WBM with 5% glycerol and 3 ppb Polymer is significantly higher compared to WBM with only 5% glycerol at same rotational speed. As expected from XCD Polymer addition, mud “low end” rheology is also increased as the polymer is added to the system. This result shows that glycerol does not affect WBM reactions with other additive, though further tests still need to be conducted to other kind of additives such as filtration loss control, salinity control, etc. 180 WBM + 5% Glycerol 160 WBM + 5% Glycerol + 3 ppb Polymer 140 Dial Reading 120 100 80 60 40 20 0 0 100 200 300 400 500 600 700 Rotational Speed (rpm) Figure 20 Viscosity Characteristics of WBM with Glycerol and Polymer Additive 3.3.3. Filtration Loss Figure 21 shows filtrate volume of WBM with various glycerol concentrations vs t^0.5. After calculating spurt loss and determining fluid loss at 7.5 minutes, API fluid loss of each sample then can be determined (shown in Figure 22). The result shows that there is 16 no significant impact of API filtrate loss compared to standard WBM (even slightly decrease at 5% and 10% glycerol concentrations), which means that no extra amount of filtration loss control additive is needed on the addition of glycerol in the mud system. 0% Glycerol 5% Glycerol 15% Glycerol 16 14 2% Glycerol 10% Glycerol Filtrate Volume 12 10 8 6 4 2 0 0 1 2 t^0.5 3 4 5 6 Figure 21 Filtrate Volume vs Time^0.5 of WBM With Various Glycerol Concentration 14 API Fluid Loss API Fluid Loss (cc) 12 10 8 6 4 2 0 0% 2% 5% 10% 15% Glycerol Concentration Figure 22 API Fluid Loss of WBM with Various Glycerol Concentration Glycerol addition in WBM also has significant impact on mud cake thickness formed. Figure 23 shows that along with increased amount of glycerol concentrations, mudcake formed by the mud would also become thinner. This could be considered as a promising result, since thin mudcake will minimize the risk of differential sticking to be happened in drilling operations. Differential sticking can occurs when a portion of the drill string (usually the drill collars) becomes embedded in the filter cake resulting in a nonuniform distribution of pressure around the circumference of the pipe. Mudcake Thickness (cm) 17 0.2 0.18 0.16 0.14 0.12 0.1 0.08 0.06 0.04 0.02 0 Mudcake Thickness 0% 2% 5% 10% 15% Glycerol Concentration Figure 23 Mudcake Thickness of WBM with Various Glycerol Concentration As shown in Figure 24, gycerol addition into WBM system have one disadvantage, it’s reducing pH value of mud filtrate that would lead to several problems both in formation drilled or in the wellbore itself. With 15% gycerol concentration, pH value of mud filtrate is decreasing up to 5.5. This undesired result could be overcome by adding lime or caustic soda to maintain proper pH value of mud filtrate. 8 Filtrate pH 7 pH 6 5 4 3 2 1 0 0% 2% 5% 10% 15% Glycerol Concentration Figure 24 Filtrate pH of WBM With Various Glycerol Concentration 4. CONCLUSIONS 1. Crude glycerol by-product of palm oil biodiesel industry has been successfully purified using 85% H3PO4 solution as much as 5% v/v of crude glycerol with the resulting glycerol content of more than 80%. 2. Synthetic-Based Mud using glycerol as base fluid has been developed. Rheological properties tests before and after thermal degradation has been conducted in order to evaluate its suitability in drilling operations. The results shows that glycerol SBM still has relatively unstable rheological properties, thus further research need to be 18 conducted to find the correct additives for glycerol SBM or to process glycerol to become glycerol ester with fatty acid before it is being utilized as base fluid for SBM. 3. Water-Based mud system using various concentrations of glycerol as lubricant additive has been formulated. Test results of WBM are : a) Extreme Pressure test shows that increase in the glycerol concentration will also increase WBM’s film strength. b) Addition of glycerol in the WBM will increase both 10 seconds and 10 minutes gel strength in the system, but it also slightly decrease viscosity characteristics of formulated mud. Therefore, addition of glycerol as lubricant in WBM should be coupled with addition of viscosity modifier additives to maintain desired rheological properties of the mud. c) WBM-glycerol system with 5% concentration has been tested to see its suitability with other additive using XCD Polymer (Xanthan Gum) as viscosity modifier. Test result shows that polymer were dissolved and works well in glycerol-WBM system to increase the desired viscosifying properties. d) There is no significant effect of addition of glycerol in mud API fluid loss, thus means that no extra amount of filtration loss control additive is needed in the mud system. e) Along with increased amount of glycerol concentrations, mudcake formed by the mud would also become thinner. This means the reduction of differential sticking risk in drilling operation. f) Glycerol will decrease pH value of mud filtrate. Decrease in pH value is proportional to the addition of glycerol concentration in mud system. This undesired result could be overcome by adding lime or caustic soda to maintain proper pH value of mud filtrate. 5. REFERENCES [1] Dasari MA. 2006. “Catalytic Conversion of Glycerol and Sugar Alcohols to Value Added Product” [Dissertation]. Missouri: Universitiy of Missouri. [2] SIDS Initial Assesment Report : Glycerol (CAS Number : 56-81-5). 2002. SIDS Initial Assessment Meeting (SIAM), France. [3] Soares, et al. 2011. “New Applications for Soybean Biodiesel Glycerol, Soybean Applications and Technology”, Prof. Tzi-Bun Ng (Ed.), ISBN: 978-953-307-2074, InTech, Available from: http://www.intechopen.com/books/soybeanapplications-and-technology/new-applications-for-soybeanbiodiesel-glycerol [4] Tyson, S. 2003. Biodiesel R&D Potential.Montana Biodiesel Workshop 8 Oktober 2003.National Bioenergy Center and Renewable Energy Laboratory US.Department of Energy. [5] Farobie, O. 2009. “Pemanfaatan Gliserol Hasil Samping Produksi Biodiesel Sebagai Bahan Penolong Penghancur Semen” [Thesis]. Bogor: Sekolah Pascasarjana Institut Pertanian Bogor. [6] Kocsisová T, et al. 2006. “G-phase from Methyl Ester Production-Splitting and Refining”. Petroleum & Coal 48(2): 1-5. 19 [7] El-Diwani G, et al. 2009. “Development and Evaluation of Biodiesel Fuel and ByProducts from Jatropha Oil”. Int J Environ Scien Technol 6(2): 219-224. [8] Hui Y. H. 1996. Bailey’s Industrial Oil and Fat Product. 5th Edition. New York: John Wiley & Sons. [9] Setyawan, et al. 2011. “Alternative Use of Castor Oil for Vegetable Oil-Base Mud Environmentally Friendly Potential Domestic Oil-Base Mud”. Proceedings, Indonesian Petroleum Association Thirty-Fifth Annual Convention & Exhibition.