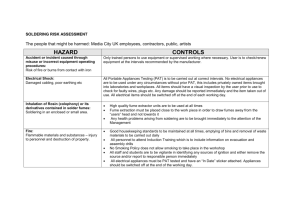

school of biological and chemical sciences safety manual

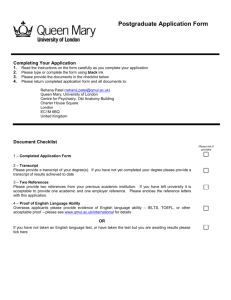

advertisement