High Temperature Paint Process Qualification - (JDSN).

advertisement

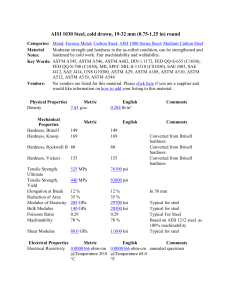

Moline Technology Innovation Center One John Deere Place Moline, IL 61265-8089 USA JDM F14X2 FORM B: High Temperature Paint Process Qualification 1) Complete all fields on page 2 before submitting this form. 2) All paints shall be approved according to JDM F14X1 before the process is submitted for JDM F14X2 qualification. Please check with the paint material supplier to ensure that JDM F14X1 has been completed. 3) Test specimens must be painted in the production process. Required samples are as follows: Submit a minimum of ten (10) samples of each production substrate to be qualified Production substrate specimens may be actual production parts or production material Test specimens shall be at least 100 mm width x 150 mm height (4 in x 6 in) Submit a minimum of ten (10) panels of each required control substrate (See table 1 for details) Control substrate panels can be purchased through ACT Test Panels (www.acttestpanels.com): ACT Test Panel Technologies 273 Industrial Drive Hillsdale, MI 49242 Ph: +1 (517) 439-1485 Fax: +1 (517) 439-1652 Table 1: Required Control Panels Production Substrates Required Control Panel Aluminized Steel Aluminized Steel ACT Product Code* APR53834 Cold Rolled Steel, Hot Rolled Steel, Cold Rolled Steel APR10286 Cast Iron, and Stainless Steel *Note: Use the listed panels or equivalent panels as approved by John Deere Materials Engineering. Example: If production parts contain Hot Rolled Steel and Cast Iron, then a minimum of the following painted specimens must be submitted. Ten (10) Production Hot Rolled Steel specimens Ten (10) Production Cast Iron specimens Ten (10) Cold Rolled Steel Control Panels 4) Return this completed form to the John Deere Moline Technology Innovation Center (MTIC) via e-mail MTICPaintLab@JohnDeere.com AND send a hard copy along with the painted substrate submission. 5) Submit painted substrate samples with a printed copy of this completed form to the John Deere MTIC at the address below: Deere & Company - Moline Technology Innovation Center ATTN: PAINT LAB One John Deere Place Moline, IL 61265 USA Document1 Revision Date: 06 April 2011 1 of 4 Moline Technology Innovation Center One John Deere Place Moline, IL 61265-8089 USA Table 2: CONTACT INFORMATION: DATE: DEERE FACTORY: DEERE CONTACT NAME: JDM F14 PERFORMANCE CLASS REQUIRED: Select JDM F14 Class ADDITIONAL REQUIREMENTS: (LIST EXCEPTIONS OR ADDITIONAL REQUIREMENTS FROM PART PRINTS) DEERE CONTACT PHONE: PART SUPPLIER NAME: PART SUPPLIER CONTACT: STREET ADDRESS: CITY, STATE, POSTAL CODE COUNTRY CONTACT PHONE: PAINTING COMPANY NAME: PAINTING CONTACT: STREET ADDRESS: CITY, STATE, POSTAL CODE COUNTRY CONTACT PHONE: CONTACT EMAIL: CONTACT EMAIL: (IF MULTIPLE PROCESS LINES EXIST AT THIS FACILITY) PAINT PROCESS NAME: Table 3: PAINT INFORMATION: COATING SUPPLIER: Please Select IF OTHER, SPECIFY TYPE: Please Select IF OTHER, SPECIFY FORMULA CODE # COLOR: LEAD, CHROME, CADMIUM: Please Select PRIMER SUPPLIER: Please Select IF OTHER, SPECIFY TYPE: Please Select IF OTHER, SPECIFY FORMULA CODE # LEAD, CHROME, CADMIUM: Please Select COLOR: Please Select Table 4: PRETREATMENT INFORMATION: PROCESS TYPE: Please Select IF OTHER, SPECIFY ABRASIVE BLASTING: Please Select BLASTING MEDIA: NO. OF STAGES: Please Select CHEMICAL SUPPLIER: CLEANER: Please Select IF OTHER, SPECIFY CONVERSION COATING: Please Select IF OTHER, SPECIFY FINAL RINSE BEFORE PAINT: Please Select IF OTHER, SPECIFY COMMENTS: Table 5: PAINTED PANEL SUBMISSIONS: Material Source Material Description 1. Please Select Please Select 2. Please Select Please Select 3. Please Select Please Select 4. Please Select Please Select Additional Information Panel Code (for control panels) COMMENTS: Document1 2 of 4 Moline Technology Innovation Center One John Deere Place Moline, IL 61265-8089 USA Table 6: Corrosion Resistance Properties TEST Salt Spray Resistance (JDQ 115) Class 1: 96 hours Class 2: 96 hours Class 3: 192 hours Class 4: 192 hours Cyclic Corrosion Resistance (JDQ 159) 20 cycles for all classes REQUIREMENT RESULTS BY SUBSTRATE 1 2 3 4 1 DFT (μm) 2 3 4 COMMENTS ≤ 3 mm Mean Creep from Scribe ≤ 8 mm Maximum Creep from Scribe 10 ASTM Blister Rating ≥ 8 ASTM Surface Rust Rating Report Mean Creep Across Scribe Report Maximum Creep Across Scribe Report ASTM Blister Rating Report ASTM Surface Rust Rating Humidity Resistance 10 ASTM Blister (JDQ 120) Rating Class 1: 96 hours Class 2: 96 hours 10 ASTM Surface Class 3: 192 hours Rust Rating Class 4: 192 hours Select Select Select Select Pass/Fail Post Thermal Corrosion Resistance (panels subjected to JDQ 147 Heat Resistance test prior to post thermal testing) ≤ 3 mm Mean Creep from Scribe ≤ 8 mm Maximum Salt Spray Resistance Creep from Scribe (JDQ 115) 24 hours for all 10 ASTM Blister classes Rating ≥ 8 ASTM Surface Rust Rating Report Mean Creep Across Scribe Cyclic Corrosion Report Maximum Resistance (JDQ 159) Creep Across Scribe 10 cycles for all Report ASTM Blister classes Rating Report ASTM Surface Rust Rating Select Select Select Select Pass/Fail Table 7: Physical & Color Properties TEST REQUIREMENT RESULTS BY SUBSTRATE 1 2 3 4 1 DFT (μm) 2 3 4 COMMENTS ≥ C (classes 1, 2) Select Select Select Select ≥ B (classes 3, 4) ≥ HB (classes 1, 2) Pencil Hardness (JDQ 11) Select Select Select Select ≥ F (classes 3, 4) Dry Adhesion (JDQ 17) Visual Color (JDQ 14) Instrumental Color (JDQ 114C) Initial 60° Gloss (JDQ 12B) Pass/Fail Document1 Pass ≤1.5 ΔE00 5-20 Select Select Select Select 3 of 4 Moline Technology Innovation Center One John Deere Place Moline, IL 61265-8089 USA Table 8: Thermal Properties TEST Heat Resistance (JDQ 147) Class 1: 360°C Class 2: 400°C Class 3: 425°C Class 4: 600°C REQUIREMENT Time: 24 hours Appearance: Pass Adhesion: ≥ C Hardness: ≥ B (classes 1, 2) ≥ HB (classes 3, 4) Color Stability: ≤15 ΔE00 (JDQ114C) RESULTS BY SUBSTRATE 1 2 3 4 24 h 24 h 24 h 24 h 1 DFT (μm) 2 3 4 COMMENTS Select Select Select Select Select Select Select Select Cyclic Temperature Cycles Completed: 3 Select Select Resistance (JDQ 148) Class 1: 360°C Appearance†: Pass Class 2: 400°C Class 3: 425°C Adhesion†: ≥ C Select Select Class 4: 600°C Thermal Shock Cycles Completed: 3 Select Select Resistance (JDQ 149) Class 1: 360°C Appearance†: Pass Class 2: 400°C Class 3: 425°C Adhesion†: ≥ C Select Select Class 4: 600°C Select Select Pass/Fail †Rating is assessed at the completion of each cycle of the test. of the third cycle, whichever occurs first. Select Select Select Select Select Select Select Select Select Select Testing is completed at the first failure or after completion TESTING INFORMATION (to be completed by testing facility) LAB NAME: CONTACT NAME: CONTACT PHONE: STREET ADDRESS: CITY, STATE, POSTAL CODE COUNTRY CONTACT EMAIL: RESULTS (Completed by John Deere ONLY) Remarks: Results: John Deere ONLY. Signature: Date: TYPE OF SUBSTRATES APPROVED (CHECK ALL THAT APPLY): ALUMINIZED STEEL COLD ROLLED STEEL HOT ROLLED STEEL CAST IRON STAINLESS STEEL LEAD FREE REQUIREMENT: ALL PAINT USED ON JOHN DEERE PRODUCTS SHALL BE LEAD FREE. FOR PURPOSES OF THIS STANDARD, LEAD FREE IS DEFINED AS <0.06% (600 PARTS PER MILLION) BY MASS IN THE DRY FILM. ALL SUBMISSIONS WILL BE SCREENED BEFORE TESTING CAN BEGIN. XRF LEAD SCREEN (ppm) JOHN DEERE ONLY NOTE: Any qualification indicated above applies only to the process and substrates documented in this report. The process will need to be re-qualified if any changes are made to this documented process, or if additional substrates are to be supplied. Document1 4 of 4