Short Term Needs

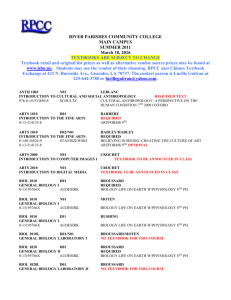

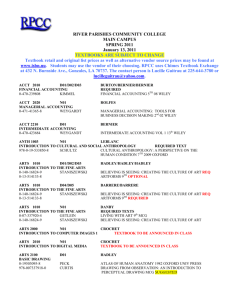

advertisement

Inventory of long and short term needs of the food sector 1. Science & Technology for Food & Manufacturing – Working Group 3.A Short Term Needs S/L term need Needs / challanges of the food sector Template 1 Keywords A01T1 - Over processing in food factories non thermal processing PEF mild processing, HPP A03T1 - Mouldiness of the surface of bakery products Infrared light mouldiness bakery industry shelf life A04T1 - Uneven cutting surface ultrasound cutting meat industry cutting surface A06T1 - Cleaning in open areas cost reduction, sustainability disinfectant A07T1 - Intelligent use of disinfectants Sustainability disinfectant A09T1 - Food safety and hygiene problems at industrial cutting cross contamination ultrasound cutting A10T1 - Recovery of (latent) heat from dust loaded gas streams heat exchanger heat recovery energy recovery A15T1 - On-spot detection of the nutrients in the final product fast detection A16T1 - Difficulties on detection of foreign bodies foreign body detection X-ray detectors A22T1 - Research in nutrition micronutrients benefits A23T1 - Effective decontamination of all food ingredients including powders and fresh produce decontamination powder dry products Long Term Needs A24T1 -Non-fouling or easy to clean surfaces food processing contamination reduction new surface structures A25T1 - High level of hygiene and food safety Cleanroom and Zoning Technology food hygiene market expansion clean label A21T1 - Automatization of counting of food products food processing quality control A02T1 - Shelf-life-elongation by production technique distribution shelf life, A05T1 - Maintaining shelf-life through global distribution chains A08T1 - Need for improved shelf life of food products shelf life waste reduction PEF A11T1 - Decontamination of factory surfaces without water use dry cleaning non-aqueous decontamination pulsed light cold plasmas A12T1 - ICT enabled intelligent manufacturing consumer’s information ICT A13T1 - By-products technology waste reduction A14T1 - Technological water wastes - membrane sieving waste water reduction membrane A17T1 - Nanotechnology for improving cleaning efficiency surface, cleaning nanotechnology A18T1 - Novel packaging materials prevent the weight loss for traditional salamis A19T1 - Novel packaging materials to be applied in HPTS packaging HPTS A20T1 -Biodegradable/compostable packaging materials suitable for long-life ambient stable thermally processed foods packaging, barrier properties shelf life, waste reduction transport enhanced quality shelf life weight loss packaging, salami 2. Industry, Knowledge Transfer and Education – Working Group 3.B S/L term need Needs / challanges of the food sector Template 1 B18T1 - Packaging - Use within the supply chain Short Term Needs B15T1 - Smart storage and commission/depot systems Keywords food safety food quality packaging systems process control process optimalisation optical sensors RFID-tags B14T1 - Multifunctional and flexible foreign body detection system not satisfactory sensitivity automatic calibration B11T1 – Man-machine interface visual oriented system effective process control B13T1 - Process control based on weight checking B16T1 -100% compliance in hygiene procedures process control cost-effectiveness reliable weight checking increasing the compliance ratio of the best practice personnel hygiene training B19T1 - Safe manufacture of powdered food ingredients B21T1 - Validation of allergen cross-contamination allergen cross-contamination cheap and reliable detection method B05T1 - Technology transfer management B06T1 - Trademark management Technology Transfer Competitiveness Dialogue Platform B07T1 - Accessing knowledge and trademark skills B12T1 - New training method based on 3D virtual design B20T1 - Networking of SMEs oriented to finding solutions for common technological threats and problems virtual design meat industry minimizing waste optimal yield cost-effective training B10T1 - Membrane technologies, BAT (Best Avalable Technologies) B09T1 - Increased efficiency in food production processes Long Term Needs B17T1 - Complete elimination of fouling development in heat exchangers B01T1 - The Innovation Factory B02T1 - The virtual business B03T1 - The value integrator B04T1 - Cooperation food processors, machine builders and RTD institutes B08T1 - Food nutritional quality management efficiency food production CO2 footprint water usage Latent heat recovery Condensation fouling insensitive self-cleaning Product functionality Cost efficiency Time to market Improved quality of food Wider food variety Increased flexibility and sustainability Network of suppliers Competences Integration of knowledge about market, methods, materials and technology break through innovation cooperation manufacturers equipment producers research institutes Communication Technology and Nutrition Knowledge Training programmes. 3. Management Systems and Business Models – Working Group 3.C S/L term need Needs / challanges of the food sector Template 1 C01T1 - Transfer of Process excellence method to food industry C02T1 - Collaborative chain pricing C03T1 - Open innovation/Co-innovation C04T1 - Addressing differences in agribusiness chain stakeholders’ interest for optimal transparency systems C05T1 - Proper problem definition and goal setting for optimal transparency systems C06T1 - Intelligent network of equipment within a processing line and along the food supply chain C07T1 - Problem of capacity utilisation sourced from seasonal nature of production C08T1 - Business models exploiting the potential of new technologies Long Term Needs C09T1 - 0 km supply chain management C10T1 - Shelf-life-elongation by production technique C11T1 - Interoperability infrastructure for supply chain integration Keywords Trans-industry methods transfer Food Manufacturing processes optimization Cost efficiency Lead time reduction Collaborative pricing Value pricing Open innovation Collaborative innovation Diverging interests in food supply chain Supply chain coordination Supply chain transparency Diverging interests in food supply chain Supply chain coordination Supply chain transparency Supply chain traceability Supply chain dynamic adjustment Networked equipment Internet of Things Network coordination Seasonality Capacity unsaturation Investments sustainability Supply chain traceability Supply chain dynamic adjustment Network coordination Business exploitation of new technologies 0 km supply chain short supply chain management food freshness guarantee Local food districts Hygiene control Increasing shelf life Integrated productionlogistics optimization food freshness guarantee Interoperability Supply chain traceability Supply chain dynamic adjustment Network coordination interoperability C12T1 - Business models enhancing local districts (international) markets Local food districts and niches Internationalization Glocal strategies 4. Economic, Social and Environmental Sustainability – Working Group 3.D S/L term need Needs / challanges of the food sector Template 1 D01.3T1 - Development of aggregate indicators D01.4 T1 - Rebound effects of food price changes Short Term Needs D01.5T1 - Indirect land use change (ILUC) D01.6T1 - Reducing food waste and hence increasing sustainability during processing by using a carbon footprint methodology D01.7T1 - Carbon footprint D01.9T1 - Simplified tools for sustainability assessment D03T1 - Communication of sustainability performance along the food chain D05T1 - Improved food safety in clean rooms D 06.1 T1 - Ergonomics techniques for food industry for healthy employees D 06.2 T1 - Collaborative chain pricing Long Term Needs D 06.3 T1 - Valorising manufacturing solutions through the anticipation of consumer needs D01.1T1 - Sustainability assessment based on a life cycle approach D01.2T1 - Methods, indicators and tools for environmental, social and economic sustainability analysis D01.8T1 - Tools for the assessment of the sustainability D01.10T1 - Life-Cycle based approaches to the evaluation of social aspects in the food sector Keywords