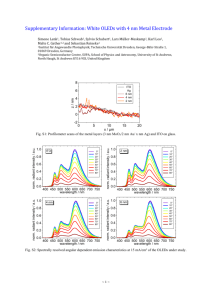

Supplementary materials

advertisement

Supplementary material for Highly stable and efficient tandem organic light-emitting devices with intermediate connectors using lithium amide as n-type dopant Dong-Ying Zhou,1,2 Feng-Shuo Zu,1 Ying-Jie Zhang,2 Xiao-Bo Shi,1 Hany Aziz2,a) and Liang-Sheng Liao1,a) 1 Jiangsu Key Laboratory for Carbon-Based Functional Materials & Devices, Institute of Functional Nano & Soft Materials (FUNSOM), Collaborative Innovation Center of Suzhou Nano Science and Technology, Soochow University, Suzhou, Jiangsu 215123, China 2 Department of Electrical & Computer Engineering and Waterloo Institute for Nanotechnology, University of Waterloo, 200 University Avenue West, Waterloo, ON N2L 3G1, Canada a) Authors to whom correspondence should be addressed. Electronic mail: h2aziz@uwaterloo.ca; lsliao@suda.edu.cn. 1 Experimental section To fabricate OLEDs, LiNH2, Cs2CO3, and organic materials were evaporated in vacuum under the pressure of 4×10-6 torr. Prior to depositing these films, indium tin oxide (ITO) conductive glass substrates with a sheet resistant of 10~15 Ω per square were well cleaned. After drying at 120 ℃, the ITO substrates were immediately transferred into the evaporation chamber to minimize the exposure time to moisture, which was helpful to decrease water absorption on ITO surface and increase device lifetime. Single and tandem OLEDs were fabricated on the fore-mentioned ITO substrates. The detailed layer structures and thicknesses of all the devices studied in this work are summarized in Table I. The EL properties of OLEDs were characterized using a programmable Agilent 4156C power source meter and a Minolta Chroma CS-100 photometer. 2 TABLE I. Layer Structures of EL Units and OLEDs. Device or Units a) A1, A2 Layer Structure ITO/MoO3(2.5 nm)/NPB(10 nm)/G-EL/Alq(10 nm)/BPhen:n-type dopant(10 nm, 1% in volume)/Al(100 nm) B1, B2 ITO/MoO3(2.5 nm)/NPB(10 nm)/G-EL/BPhen:n-type dopant(10 nm, 1% in volume)/HAT-CN(10 nm)/G-EL/Alq(10 nm)/BPhen:n-type dopant(10 nm, 1% in volume)/Al(100 nm) C1, C2 ITO/MoO3(2.5 nm)/NPB(10 nm)/G-EL/Alq(10 nm)/BPhen:n-type dopant(10 nm, 1% in volume)/HAT-CN(10 nm)/Al(100 nm) G-EL NPB(40 nm)/Alq:C545T(15 nm, 0.5% in volume)/Alq(20 nm) BS ITO/HAT-CN(10 nm)/B-EL/TmPyPB(20 nm)/Liq(2.5 nm)/Al(100 nm) YS ITO/HAT-CN(10 nm)/Y-EL/Liq(2.5 nm)/Al(100 nm) WT ITO/HAT-CN(10 nm)/B-EL/BPhen:LiNH2(10 nm, 1% in volume)/HAT-CN(10 nm)/Y-EL/Liq(2.5 nm)/Al(100 nm) a) B-EL NPB(60 nm)/TCTA(10 nm)/mCP:FIrpic(15 nm, 15% in volume)/TmPyPB(20 nm) Y-EL NPB(60 nm)/TCTA(10 nm)/TPBi:PO-01(20 nm, 6% in volume)/TPBi(40 nm) The subscripts 1 and 2 denote that the n-type dopants used in devices are Cs2CO3 and LiNH2, respectively. The materials Alq, NPB, C545T, TCTA, mCP, TmPyPB, TPBi, FIrpic, and PO-01 stand for tris(8-hydroxyquinoline)aluminum, diamine, N,N′-diphenyl-N,N′-bis(1-naphthyl)-1,1′-biphenyl-4,4″- 10-(2-benzothiazolyl)-2,3,6,7-tetrahydro-1,1,7,7-tetramethyl-1H,5H,11H-(1)- benzopyroyrano(6,7,8-i,j)quinolizin-11-one, dicarbazolyl-3,5-benzene, 4,4’,4”-tris(N-carbazolyl)triphenylamine, 1,3,5-tri(m-pyrid-3-yl-phenyl)benzene, phenylbenzimidazole-2-yl)benzene, N,C2′]picolinate, iridium(III) N,N′- 1,3,5-tris(N- iridium(III)bis[(4,6-difluorophenyl)pyridinatobis(4-phenylthieno[3,2-c]pyridinato-N,C2′)acetylacetonate, respectively. 3 FIG. S1. (a) Current density versus voltage (J-V) and (b) current efficiency versus current density (CE-J) characteristics of devices C1 and C2. FIG. S2. Schematic of tandem phosphorescent white OLEDs (device WT). 4 FIG. S3. (a) Current density versus voltage (J-V) and (b) current efficiency versus current density (CE-J) characteristics of the single blue/yellow and tandem white phosphorescent OLEDs (devices BS, YS, and WT). Inset: EL spectrum of the single blue/yellow and tandem white phosphorescent OLEDs. 5 FIG. S4. Fitting curves of the luminance decay of devices A2 and B2. 6