Base oil - Springer Static Content Server

advertisement

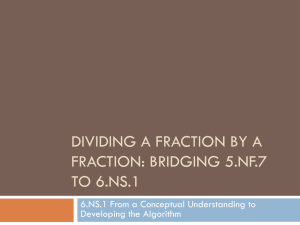

ELECTRONIC SUPPLEMENTARY MATERIAL TABLE OF CONTENTS LCI DATASETS FOR THE MINERAL CHAINSAW OIL 2 1. Extraction of crude 2 2. Base oil manufacture 2.1. Baseline scenario 2.2 Sensitivity analysis 3 3 5 LCI DATASETS FOR THE ADDITIVES 6 1. Choice of the additives 6 2. Modeling of the additives 7 Page | 1 LCI datasets for the mineral chainsaw oil 1. Extraction of crude Table 1 Inventory of inputs associated with the extraction and the transport steps of crude oil Extraction Diesel consumption Transport to the refinery Heavy fuel oil Value Unit (all data per ton of crude oil) Source 490 MJ Eurobitume 2011 18.1 kg Eurobitume 2011 Table 2 Inventory of outputs associated with the extraction and the transport steps of crude oil Value EXTRACTION Emissions to air CO2 CO SO2 NOx CH4 NMVOC Particulates Unit (all data per ton of crude oil) Eurobitume 2011 70140 366 760 140 170 350 93 g g g g g g g Emissions to water Oil 4.11 g Emissions to soil Oil 10.23 g TRANSPORT Emissions to air CO2 CO SO2 NOx Hydrocarbon Source Eurobitume 2011 56443 64,3 964 864 4.95 g g g g g Page | 2 2. Base oil manufacture 2.1. Baseline scenario Crude oil Atmospheric distillation Gaz, naphta, gas oil Atmospheric residue Vacuum distillation Vacuum gas oil Vacuum residue Asphalt Deasphalting Vacuum distillate Deasphalted fraction Solvent extraction Aromatic components Dearomatized fraction Hydro-treatment Hydro-treated fraction Solvent dewaxing Wax Dewaxed fraction Hydrofinishing Impurities Base oil Fig. 1 Flowchart of the production of mineral base oil Page | 3 Table 3 Yield ratios of products by the base oil production chain Refining step Atmospheric distillation Gaz Naphta Gas oil Atmospheric residue Vacuum distillation Vacuum gas oil Distillate Vacuum residue Deasphalting Asphalt fraction Deasphalted fraction Solvent extraction Aromatic components Dearomatized fraction Hydro-treatment Hydro-treated fraction Solvent dewaxing Wax Dewaxed fraction Hydrofinishing Impurities Base oil Yield per process step (%w) Source Fehrenbach, 2005 2 21 36 41 Fehrenbach, 2005 4 56 40 Fehrenbach, 2005 30 70 Fehrenbach, 2005 35 65 Fehrenbach, 2005 100 Fehrenbach, 2005 20 80 Mortier et al. 2010 5 95 Table 4 Energy and auxiliary consumption of the process steps of base oil refining chain (Fehrenbach 2005) Step Atmospheric distillation Refinery gaz Heavy fuel Petroleum coke Natural gas Vacuum distillation Refinery gaz Heavy fuel Petroleum coke Natural gas Deasphalting Refinery gaz Heavy fuel Petroleum coke Natural gas Solvent extraction Refinery gaz Heavy fuel Petroleum coke Natural gas NMP Process water Hydro-treatment Refinery gaz Heavy fuel Petroleum coke Consumption (data per ton of input) 415.6 MJ 221.5 MJ 36.98 MJ 18.4 MJ 415.6 MJ 221.5 MJ 36.98 MJ 18.4 MJ 183.4 MJ 554.3 MJ 6.21 MJ 1.96 MJ 623.5 MJ 429.0 MJ 48.18 MJ 27.39 MJ 0.8 kg 49 kg 452.1MJ 653.82MJ 34.28MJ Page | 4 Natural gas Dewaxing Refinery gaz Heavy fuel Petroleum coke Natural gas Dichloromethane Methyl Ethyl Ketone Process water Hydrofinishing Refinery gaz Heavy fuel Petroleum coke Natural gas Process water 13.8MJ 1160.3 MJ 1790.4 MJ 99.27 MJ 31.05 MJ 0.6 kg 0.4 kg 169 kg 368.94 MJ 461.38 MJ 33.19 MJ 11.49 MJ 73 kg 2.2 Sensitivity analysis Table 5 Production yield ratios by the mineral base oil production chain according to Fehrenbach (2005) and Mortier et al. (2010) Refining step Atmospheric distillation Gaz Naphta Gas oil Atmospheric residue Vacuum distillation Vacuum gas oil Distillate Vacuum residue Deasphalting Asphalt fraction Deasphalted fraction Solvent extraction Aromatic components Dearomatized fraction High pressure hydrogenation Hydrogenated fraction Solvent dewaxing Wax Dewaxed fraction Hydrofinishing Impurities Base oil Yield per process step (Fehrenbach 2005) Yield per process step (Mortier et al. 2010) 2 21 36 41 2 21 36 41 4 56 40 4 56 40 30 70 65 35 35 65 49 51 100 / 20 80 24 76 5 95 5 95 Page | 5 LCI datasets for the additives 1. Choice of the additives Polymethacrylate (PMA) was chosen as a classical pour point depressant found in chainsaw oils. PMA can be used in the formulation of mineral and vegetable based lubricants (PMA being diluted either in mineral or in vegetable oil). PMA additives are synthesized by polymerization of various methacrylate monomers that differ by length of the pendant side chains (Rudnick 2009). Methacrylate monomers were chosen as representative for modeling PMA. These monomers can be produced by the reaction of methyl methacrylate with alcohol. The steps involved in their production are shown in Fig. 2. R OH + CH3 CH3 + H2C H2C H3C OH OR O CH3 O O Fig. 2 Methacrylate monomer synthesis Butylated hydroxytoluene (BHT) was chosen as a classical anti-oxidant for vegetable oil. Industrially, BHT is obtained by reacting p-cresol with isobutylene in the presence of a strong acid (see Fig. 3). p-Cresol is commercially produced by toluene oxidation via sulfonation with sulphuric acid (Sad et al. 2008). In industry, isobutylene is traditionally produced by dehydrogenation of isobutane and butane (Sangalov et al. 2001 ). OH OH CH3 + 2 (H 3C) 3C C(CH 3)3 H2C CH3 CH3 CH3 Fig. 3 BHT synthesis Page | 6 2. Modeling of the additives The proposed ecoinvent correspondences and assumptions for modeling additives are reported in Table 6. Table 6 Main data and assumptions for the simplified LCA of additives Category Selected additive Pour point depressant Polymethacrylate (PMA) Anti-oxidant Butylated hydroxytoluene (BHT) Proposed correspondence (Ecoinvent database) Methyl methacrylate, at plant RER 1-Pentanol, at plant RER Toluene, liquid, at plant RER Propane/Butane at refinery, RER Relative compositi on 54% 46% 49% 51% Decision criteria Proxy synthesis process Proxy synthesis process and proxy product Page | 7