focal bht anicell

advertisement

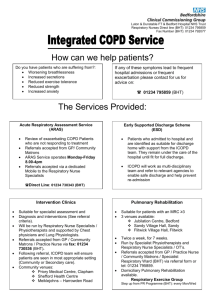

The NEWSLETTER Winter 2013 FOCAL BHT ANICELL By Mike Street, COO FOCAL FOCAL is a Micro SME based in the West Midlands. It is a Hi-Tec consulting firm working on such diverse projects as brown field infrastructure projects, UK-China-UK rail shuttle, Surface and Underground rail freight, Rail/Road Logistic Hubs, Ro-Ro pallet systems, commercial exploitation of Space Station Solar technology, anti-microbial coating products, nano fibre recyclable composite material to replace carbon fibre, and several others that are still confidential. In this article FOCAL wish to present the new Back Haul Trolley System that allows revenue to be gained from back hauls for road, rail and shipping operators. The BHT uses the new EU project backed Nancore material - a nano fibre recyclable composite material designed to replace carbon fibre. This will be described in the second part of the article. BACK HAUL TROLLEY The ‘BHT I’, (left of picture 1200 x 1000) is specifically designed to fit European standard pallets and industry wide Folding Logistics Containers - The BHT II, (right of picture, 2500 x 2100) is designed to carry larger freight such as engine racks and whole vehicles on the in-bound leg of the journey. In 2003 JLR (then part of Ford) were seeking innovation/cost down in their supply chain and the BHT trolley was specifically developed to provide it. There was no appropriate means of loading empty out-bound finished vehicle rail wagons; trains return to the automotive manufacturing plants empty, 24 wagons at a time. FOCAL have designed and patented their BHT for the carriage of engines, transmissions and other in-bound components on the return (inbound) journey. Thus the auto OEMs will have an opportunity to reduce their current logistic costs. The prize is large - currently there is the equivalent of over 10,000 lorry movements pa which move on bi-level rail wagon. All these could be a back haul on the same rail wagons. The BHT allows any palleted parts or stillages (which fits within the BHT 2.5mx2.1m Page 1 THE SOCIETY OF MANUFACTURERS AND TRADERS LIMITED SMMT, 71 GREAT PETER STREET, LONDON SW1P 2BN T +44 (0)20 7235 7000 The NEWSLETTER Winter 2013 foot print) to be loaded onto any surface that is used to deliver a car. The BHT is also very factory friendly. Individual BHTs can be manually pushed line side. The BHT is unique in that it can be towed in rakes of up to 17 Trolleys, as opposed to the 3 Trolley rakes which are standard in every automotive assembly plant. The BHT system was deliberately designed to provide minimum change in the automotive OEM operation. It was designed to use the standard Linde or Maxim electric tow truck used in most automotive OEM plants. The composite & steel design uses existing and new technology to improve upon the standard steel trolley used in the sector. The BHT provides easy handling in transit and added convenience and safety in the assembly plant. Page 2 The BHT design consists of recycled composites and rubber combined with a foam - the bi-product of an EU funded FP7 NMP programme Project 2008-2012, the detail are available from FOCAL. THE SOCIETY OF MANUFACTURERS AND TRADERS LIMITED SMMT, 71 GREAT PETER STREET, LONDON SW1P 2BN T +44 (0)20 7235 7000 The NEWSLETTER Winter 2013 Autorailcar loading Like the standard trolley (dollies) BHT can be stacked. Unlike the standard steel trolley with its protruding coupling bar (an accident waiting to happen), the BHT Trolley coupling retracts inside the Trolley Chassis boxed section when it is disengaged from the tow truck. BHT is available now for further details please call FOCAL on 0845 557 8082 or 0777 1910 302 ANICELL ANICELL was created in an EU funded FP7 Programme that developed a new material to replace the reliance on Balsawood and PVC composites. This was the collaborative work of several European Universities and tested at the University of Coventry. Another of the BHT’s new innovations is a cable operated deadman’s drum brake which engages when the trolleys begin to descend either a slope or a ramp. This is especially important when the BHT is being towed into a bi-level rail wagon normally used for cars. Page 3 AniCell can be used either as structural panels or as the core of sandwich panels and, depending on the additives and/or the cellular structure type, it can fulfill different types of requirements and be used for different applications and/or configurations. THE SOCIETY OF MANUFACTURERS AND TRADERS LIMITED SMMT, 71 GREAT PETER STREET, LONDON SW1P 2BN T +44 (0)20 7235 7000 The NEWSLETTER Winter 2013 AniCell cores and panels are based on a readily available and economic polymer such as polypropylene The multifunctionality of AniCell products makes them potential substitutes for current products in many applications AniCell FR and AniCell PFR can be produced in a density range between 250 and 300 kg/m3 The new FP7 NMP 2008-2012 Programme funded Nancore Material is being considered by overseas OEM’s. The difference between the conventional compression molding process and the ICM route lies in the pressure applied to the material during the foaming step. It is possible to generate low density materials without crosslinking the polymeric matrix, so they are fully recyclable by conventional processes. The ICM route allows the use of a wide variety of fillers, (from nanoparticles to conventional microsized fillers) and up to medium-high contents, (up to 40%). The ICM route and halogen free flame retardant technology combine to generate a new class of lightweight fire resistant cores and panels. Details on ANICELL are available from FOCAL on 0845 557 8082 or 0771 910 302 This publication contains general information and, although SMMT endeavours to ensure that the content is accurate and up-to-date at the date of publication, no representation or warranty, express or implied, is made as to its accuracy or completeness and therefore the information in this publication should not be relied upon. Readers should always seek appropriate advice from a suitably qualified expert before taking, or refraining from taking, any action. The contents of this publication should not be construed as advice or guidance and SMMT disclaims liability for any loss, howsoever caused, arising directly or indirectly from reliance on the information in this publication. AniCell’s principle properties are: They exhibit excellent specific stiffness and strength due to their anisotropic cellular structure Some of the materials commonly used for the applications in which AniCell could be an option, are polyurethane foams or crosslinked PVC foams AniCell cores and structural panels can be used as thermal insulators due to their low thermal conductivity. The open cell version of AniCell, AniCell OC, can be used as vibration dampener or as acoustic absorber material AniCell FR offers fire resistance using halogen free technology AniCell is an economically viable alternative to more commonly used products AnicCell products present clear advantages in cost, performance and sustainability over the currently used PU and PVC foams Page 4 THE SOCIETY OF MANUFACTURERS AND TRADERS LIMITED SMMT, 71 GREAT PETER STREET, LONDON SW1P 2BN T +44 (0)20 7235 7000