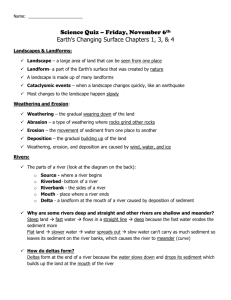

erosion control - South Dakota Department of Transportation

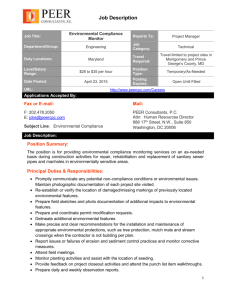

advertisement