Basic Mechanical Design Guidelines

advertisement

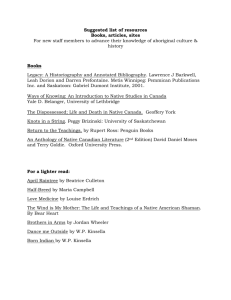

University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 1 1.01 BACKGROUND .1 This section is intended to assist the Mechanical Consultant and other design team members during the design process by answering questions about how the University of Manitoba builds, operates, and maintains mechanical systems in buildings. The use of any of this information will NOT reduce in any way the designers' professional responsibility for a complete design and fully functioning installation necessary to meet University needs. It remains the designers' responsibility to ensure all aspects of design, drawings, and specifications are complete and meet the University’s requirements. .2 It is not intended to be a "book of rules" and any item is open to discussion. If there are questions about this information or proposals of alternate solutions, discuss them with the Project Manager and A & E Services. By maintaining an open dialog between the University and the design team, misunderstandings can be kept to a minimum. .3 The following guidelines are intended to form the basis of system design. Items to be modified will need to be done in consultation with the University Project Manager and the University A & E Services. .4 The Design Consultant is expected to analyze various alternative systems based on lifecycle costs as well as ease of maintenance, noise concerns, and similar issues. .5 These Guidelines as well as the Physical Plant Design Details and Master Specification sections can be downloaded from the University of Manitoba Physical Plant Website located at: http://www.umanitoba.ca/campus/physical_plant/departments/a&e_masterspecs.html .6 1.02 1.03 The website information is periodically updated so latest information must be accessed before starting any project and before submitting material for review or approval. Information is dated at time of loading on the website so it may be easily checked to ensure current updates are being used. AIR INTAKE & EXHAUST .1 Outside air intakes shall be located to bring in clean air and shall be kept out of the path of exhaust, vehicle fumes, refuse containers, bus stops, loading zones, and similar problem areas. Care must also be taken to ensure that exhausts from adjacent buildings are not captured in outside air intakes. .2 Exhaust system outlets are to be located so as to not create noise, hazard, or odour problems for project building or adjacent buildings. AIR SYSTEMS .1 100% shutoff variable air volume systems are not permitted on exterior zones except when connected to CO2 sensors. Minimum airflow must be maintained to satisfy ventilation requirements. .2 Economizer (free-cooling) cycle shall be utilized on all systems over 2000 cfm (with the exception of computer rooms or other rooms with strict RH requirements) for areas requiring year-round cooling. .3 All systems 5 tons and over shall be provided with economizer cycles as well as a return or exhaust fan to provide positive relief. .4 Select VAV boxes with a capacity 15% in excess of maximum design air flow rates. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 2 1.04 .5 Size supply air systems with 10% excess capacity to allow for future load changes. .6 The maximum required design airflow for all fans shall not exceed 90% of the manufacturer’s maximum rated airflow at design pressure conditions. .7 Air unit plenums shall be provided with hinged, sealed access doors and lighting for inspection of each chamber. Secure doors with heavy duty quick access fittings that are operational from both sides of the door. Arrange door swings so that the fan static pressure holds the door in a closed position. .8 Locate air system intakes sufficiently apart from ventilation exhausts, chimneys, plumbing and lab vents, vehicle exhausts, loading docks and ground contaminants to ensure crosscontamination does not occur. Wind study testing may be required if exhausts or equipment discharge locations could possibly contaminate an air intake or adjacent buildings. ANTIFREEZE SYSTEMS Mechanical systems exposed to freezing conditions shall be provided with antifreeze solutions capable of handling the potential temperatures. Antifreeze shall be non-toxic polypropylene in all situations. Ethylene solutions are not permitted to be used. Propylene solutions shall be colored green to permit easy verification in the field. 1.05 APPROVAL PROCESS University of Manitoba projects include a number of stakeholders that participate in the final design solution. These stakeholder groups cover issues such as: Asbestos work Commissioning Confined space entry Fall protection Fume hood work Hoarding & excavation Hot works Lock-outs Overhead power lines Personal protective equipment Service connections & shutdowns Restricted area access Working after hours The design team must meet with these groups during the design process to ensure that individual issues are properly addressed and University standards are being maintained. The University of Manitoba Project Manager will assist in meeting with the various groups during the design process. 1.06 BALANCING VALVES .1 Balancing valves shall automatic flow control type (such as Griswold) and not manually adjustable valves that can be easily reset during maintenance or repair procedures. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 3 1.07 BYPASSES .1 1.08 1.09 1.10 Bypasses shall be installed around water meters, control valves, and pressure reducing stations serving critical areas. CENTRAL CHILLED WATER SYSTEMS .1 The chiller run-around pumps are constant volume, decoupled from the distribution loop, and as load is added to the system, the load is decoupled from the distribution loop via a "primary / secondary" piping bridge. Building pumps are typically constant volume, but variable-speed pumps may be warranted in some cases. .2 Fort Garry Campus - The distribution loop is sized for a 10°F water temperature difference and individual buildings are to be designed for chilled water temperature ratings of 44°F (EWT) to 54°F (LWT). .3 Bannatyne Campus - The distribution loop is sized for a 10°F water temperature difference and individual buildings are to be designed for chilled water temperature ratings of 42°F (EWT) to 52°F (LWT). CENTRAL STEAM SYSTEMS .1 During the winter, the Fort Garry Campus central steam is supplied at 100 psig and 460°F, which places the steam into superheat condition. The highest steam safety valve in our Central Energy Plant is set at 257 psig so all pressure tests on main steam supply systems will need to be performed at 390 psig (1.5 times the 257 psig maximum rating). .2 Smaller boilers are used on the Fort Garry Campus during the summer to supply 80psig saturated steam. All connected heating equipment that is meant to operate year round must be sized to handle this steam supply variation from winter levels. .3 Fort Garry steam is shut down annually for a two week maintenance period. Back up heating may be required in some areas to ensure continual supply of necessary heating. .4 On the Bannatyne Campus, steam is supplied from Health Sciences Centre (HSC) central plant at 125psig saturated. Shut down periods of this steam supply are to be verified with HSC. The highest steam safety valve in the HSC Central Energy Plant is set at 180 psig so all pressure tests on main steam supply systems will need to be performed at 270 psig (1.5 times the 180 psig maximum rating). COILS .1 Air unit coils to be equipped with constant volume pumping. Temperature control on coils to be provided by variable fluid temperature control and not by variable flow. Provide circulating pumps on all coils as per Mechanical Details. .2 Where air units require heating and cooling coils, investigate the option of using a single coil for both heating and cooling to simplify the installation and reduce installation and maintenance costs. The combined coil must be operated on glycol to prevent freezing and the district chilled/Recuperator water return system shall be provided with dual control valves selected for the heating and cooling flow requirements. .3 Air units with separate heating and cooling coils shall have heating coils installed upstream of cooling to assist in protecting the cooling coils from freeze-up in spring and fall when system may be filled with chilled water. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 4 .4 1.11 COMMISSIONING .1 1.12 1.13 1.15 Refer to Section 01810 Quality Commissioning for the details of The University of Manitoba commissioning process. COOLING EQUIPMENT .1 Where water-cooled equipment is specified, the campus chilled water return system shall be used. All chilled water that is used for cooling is to be returned to the piping system. Dumping cooling water to waste is NOT permitted. Chilled Return Water is available at 11ºC (52ºF) in cooling season and 21ºC (70ºF) during heating season. Review equipment needs with Physical Plant Department. .2 Chilled water coils are to be equipped with a University of Manitoba lay-up installation that provides airflow through the coil piping during the winter to prevent freezing damage. .3 Condensate drains are to be run by gravity. No condensate pumps are to be used unless the use of gravity drainage systems is not possible. COORDINATION OF DRAWINGS .1 1.14 All cooling coils operating on chilled water shall be equipped with the University of Manitoba winter lay-up system. Please contact the University for the necessary coil layup details. The Mechanical Consultant is responsible for coordinating the mechanical, fire protection, and plumbing plans with all other disciplines. Claims by the Contractor resulting from lack of coordination shall be administered by the University of Manitoba Project Coordinator with any additional project costs potentially charged back to the Consultant. DDC CONTROLS .1 With the exception of unit heaters and entrance heaters, all control systems shall be Delta DDC systems and shall be constructed, installed, and programmed to University of Manitoba standards. Review requirements with the U of M CCMS shop (Mr. Doug Cook at 474-6883). .2 CO2 sensors shall be used to control ventilation rates on all rooms occupied by more than 6 people. .3 All DDC panels are to be provided with emergency and UPS power support to ensure seamless operation through power interruptions. DESIGN EVALUATION .1 The design shall meet with the assigned University of Manitoba project review personnel during the design process to coordinate the progress of the work. .2 Design reviews will be conducted whenever deemed necessary, but are considered mandatory for the schematic, design development, and final review submittals. .3 Each design review comment (regardless of the source) is to be addressed in writing by the Consultant prior to completing the next phase of the project design. This report shall be submitted to review team leader. .4 The following information is required to evaluate the design at each respective Phase: February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 5 ITEM SCHEMATIC PHASE (33%) Specification System & Material Description DESIGN DEVELOPMENT PHASE (66%) Outline Specification in Word Format Major Equipment CAD Files Site Landscaping Building Envelope Sample of AutoCAD Files Sample of AutoCAD Files to Complete Set of AutoCAD U of M Standards files Utility Details Dimensions Lighting Plan Site Drainage Pipe Sizes Connection Details Existing Conditions Existing Irrigation Irrigation Legend Irrigation Plan Piping Diagrams Pipe Sizing Design Calculations Typical Elevations Building Cross Sections Material Designations Typical Wall Sections Roof & Drainage Plan Roof Details Roof Mounted Equipment Fire Rated Separations Dimensioned Plans Reflected Ceiling Plans Typical Floor Plans Mech, Elect Spaces Elevators Elevator Locations Equipment Rooms Plumbing & Piping Location of Risers Fixture Layouts Fixture Cut Sheets Equipment Descriptions Piping Plans System Schematics Duct Layouts System Description Equipment List Intake & Exhaust Locations Equipment Layouts System Schematics Controls Fire Protection Lighting Complete Specification in Word Format Site Utilities Utility Requirements Future Expansions Building Interior HVAC CONSTRUCTION DOCUMENT PHASE (99%) Location of Panels, Remote Controllers, Thermostats &Meters Complete Specifications Pipe Sizes Piping Details Design Calculations Equipment Details Installation Details Design Calculations Control Equip List Control Drawings Field & Network Layout &Schematics Panel, Field & Network Details Points List Low Voltage Dist. Connection to Utilities Riser Diagrams Sprinkler Valve Location Sprinkler Valve Details Zones w/ Foot Candles Fixture/ Switching Layouts Fixture Types Light Level Calculations Piping Layouts Pipe Sizes Design Calculations Fixture Schedule Installation Details Design Calculations February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 6 Power Distribution Single Line Diagrams Electrical Legend Fire Alarm Panel Locations Building Distribution Voice / Data V/D Room Locations Equipment Layouts Load Summary Panel Locations Panel Schedules Load Estimate Design Calculations Fire Alarm Zones Connection Details Riser Diagrams Connections to FA Device Locations Connections to HVAC Riser Diagrams Racking Layouts Conduit Layouts Connection Details V/D Outlet Locations Cable Schedule Special Waste Handling Waste Storage Areas Details of All Support Areas & Equipment Service Facilities Service Elevator Universal Access Washroom Locations Equipment Details Installation Details Personal Safety Design Considerations Special Systems Details of Systems 1.16 DESIGN CONDITIONS The following are general design guidelines for inside and outdoor design conditions. Design Guidelines for Indoor and Outdoor Temperatures Area Comfort Areas (Note 1) Season Summer Winter Indoor 72°F DB 75°F DB 35%RH Outdoor 87°F DB, 75 °F WB - 40°F DB Labs & Critical Areas Summer Winter 87°F DB, 75 °F WB - 40°F DB Animal Rooms (Note 2) Summer Consult with User Consult with User As specified in latest edition of "Guide to the Care and Use of Experimental Animals" as published by the Canadian Council on Animal Care (CCAC) Winter Note 1 Note 2 87°F DB, 75 °F WB - 40°F DB Consideration shall be given to morning warm-up & cool-down cycles. Typically these systems are required to be 100% outdoor air systems and specified temperatures shall be maintained 24 hours per day. Minimum and maximum relative humidity requirements shall be identified by the Design Consultant in conjunction with the end user. 1.17 DESIGN CRITERIA .1 Important mechanical areas of coordination for the University of Manitoba: Connections to existing utility distribution systems, including capacity and location. Temporary construction water and sewer points of service Distribution concepts including piping and ductwork February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 7 1.18 1.19 Load calculations for campus utilities Noise criteria levels for all spaces Energy efficiency efforts to match/exceed on-going conservation initiatives Special systems design (research and diagnostic equipment, and other specialized equipment) Design systems and components with maximum reliability, maximum flexibility, and minimum operation and maintenance cost. Give full consideration for future system alterations with a minimum of system shutdowns. Accommodate preventive maintenance without a major building shutdown. Maintenance accessibility is very important. Meet current regulations for access, worker safety, including fall protection. Use of Fort Garry campus heat recovery Recuperator system for domestic hot water, space, and fresh air heating. .2 Since laboratory buildings will need constant renovation to keep up with changing technology, the building systems must be designed and installed to allow for on-going revisions. Provide isolation valves and devices for each piece of equipment, and each lab module. Down feed all mechanical systems except the waste lines to minimize the number of floor penetrations. .3 Coordinate mechanical equipment located on the roof with the Architect. Minimize the number of roof penetrations. .4 Provide access for shafts that contain systems that require periodic maintenance, repair, or replacement, e.g. piping, fume ducts, etc. Accessibility will also be required if space is provided for future mechanical equipment. Provide access through access doors or removable walls and space within the shafts. Accessible shafts are preferred over removable walls. Coordinate access method with Architect. DOMESTIC HOT WATER .1 Domestic hot water heating is to be provided primarily with Recuperator energy and then topped up with steam heating. A final electric heating source is to be provided to ensure domestic hot water supply during periods when both the Recuperator and steam are shut down (typically once per year). .2 The electric DHW heating system is to be sized for 100% capacity to maintain normal building operations. .3 All instantaneous electric heaters are to be provided with flow switches to shut down units in case of flow failure. .4 Domestic hot water is to be heated and stored at a minimum of 140°F (60°C) to affect the appearance of Legionellae and then be tempered through a mixing valve to desired delivery temperatures. DRAWING STANDARDS .1 Mechanical drawings are to be completed in accordance with University of Manitoba drawing standards. These standards include line weights, layers and formatting of the drawings. Failure to meet standards will require reworking of the drawings to meet these standards. .2 Equipment Room layouts to be drawn in 1:50 (¼” = 1 foot) scale and shall include plan and critical sections. Equipment weights are to be shown on each item. Also show minimum access, maintenance, repair and replacement space for each item. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 8 1.20 1.21 .3 Ductwork and equipment drawings are to be prepared with double linework to improve evaluation of impact of duct and equipment installations. .4 Construction and As-built drawings shall include all equipment setpoints and operating parameters such as discharge temperatures, pump flows and capacities of capped off future connections. These settings are to allow ease of review of actual operating conditions against as-constructed conditions, to assist in Commissioning processes, and in future renovations. ELECTRICAL ROOMS .1 All electrical rooms that contain heat-generating equipment shall be provided with ventilation systems that use outside air to remove all heat produced within the space and to control room temperatures to setpoint. .2 Ventilation systems shall include a motorized dampered fresh air intake, 30% efficient air filters, and a matching exhaust system operated by a room thermostat. A rise in room temperature will open the intake damper and start the exhaust fan. .3 The fresh air intake will be ducted down to within 450mm (18”) of the floor and the exhaust will remove air at the highest reasonable point. .4 A room temperature sensor shall be connected to provide a high temperature alarm on the campus Delta system should room temperature rise above set limit. ELECTRIC MOTORS .1 Motor driven systems shall use “off the shelf” premium efficiency motors so, if the motor fails, an appropriate replacement can be located in stock in Winnipeg. If the Consultant creates a need for an unusual motor (inverter rated, 900 RPM, metric, etc.) it may not be easily replaced in kind when it fails. .2 Motors to be selected to operate at peak efficiency point (typically 75% of rated load capacity) Use NEMA rated, 1800-RPM motors with Class F insulation appropriately matched to the driven equipment. Do not select motor speeds requiring V-belt drive reduction ratios greater than 6:1. .3 Identify the type of control for every motor used. .4 Motor bearings shall be factory lubricated for motors less than 1/3 hp. Sleeve bearings will only be permitted for fractional HP motors and where specifically recommended by the equipment manufacturer as the better type of bearing for the application. .5 Vertical shaft motors shall be equipped with suitable thrust bearings. .6 Shaded pole-type motors less than 1/8 HP are not acceptable. .7 Motors shall be open drip-proof or T.E.F.C. construction. Totally enclosed or explosion proof types shall be provided where conditions dictate. .8 Special equipment for labs, kitchens, and other areas may have special requirements. Evaluate and provide circuiting as necessary. .9 Provide housekeeping pads for all motor installations. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 9 1.22 .10 Motors shall be sized to operate between 70% and 95% of full motor load when running at full 60 Hz speed. If a larger future load is anticipated, size the motor mounting pad to accommodate the larger anticipated motor frame size. .11 Use the following motor voltage ratings: 120 VAC single phase for motors < ½ HP 120 VAC single-phase for motors > ½ HP used for intermittent light duty such as sump pumps, door operators, unit heaters, etc. 208 VAC single phase may be used for motors <1 HP. 208 VAC, 3 phase for motors >½ HP in continuous operation. 600 VAC, 3 phase is preferred for all motors >1 HP. Variable speed applications require motors nameplate rated for inverter duty (e.g. IV). All motors >50 HP to have soft start. Coordinate all motor power selections with University of Manitoba Physical Plant. Do not expose motors to the weather. Install motors within the building or in suitable enclosures. If motors are not housed within the building structure, specify totally enclosed type motors, even where a weatherproof enclosure is provided. EMERGENCY GENERATOR .1 Emergency generator fuel supply shall be sufficient to permit 24-hour operation at full load. .2 Emergency generators shall not be installed below grade or in areas where large components cannot be removed from the building. .3 Generator room sprinklers shall be preaction type that does not contain water within the generator room unless there is a fire condition. .4 Air dampers shall be controlled to fail open on power failure. .5 Generator rooms shall be provided with temperature sensors connected to DDC system and provide alarm should temperatures drop below 13ºC (55ºF). Where DDC system is not present, provide audible alarm with trouble light and silence switch in suitable location. .6 Provide catwalk system for generators that are elevated above normal working heights. This is required with large units or generators mounted on skid fuel tanks. Catwalks to provide maintenance access to all areas of the generator. Catwalks to be provided to ensure that the top of the unit control panel is not more than 1.8m (6’) above standing platform. .7 It is expected that generator room temperatures will experience high temperatures during generator operation. Room design must take operating conditions into account when addressing thermal and acoustic characteristics. Room temperatures must not exceed Manufacturer’s limits for every piece of equipment within the space. .8 Day tanks to have overflows piped back to main fuel tanks. Overflow return is to be by gravity and not rely on pumps. .9 Main fuel tanks to be provided with indicating light and alarm at fill station to indicate that fill level has been reached. Alarm panel to have acknowledge button to shut off alarm and light once tank has been filled to set point. Panel to also have test button to check operation of light and alarm before filling begins. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 10 .10 1.23 EQUIPMENT, PROCESS, AND NON-TYPICAL HEAT GAINS LOADS .1 1.24 1.25 1.27 Equipment or process heat gains, excluding people, lights, conduction, and solar loads, in critical and special areas such as computer rooms, microcomputer labs, and research labs shall be scheduled on the drawings by room number for future reference. EQUIPMENT LOCATIONS .1 Terminal units and air handling equipment shall not be located above an occupied space without prior approval from the Physical Plant Department. .2 All equipment must be readily accessible for maintenance. Equipment located 4 ft or more above the finished floor level shall include access platforms or walkways accessed by a set of stairs. This typically does not apply to ceiling mounted items such as reheat coils but each application is to be confirmed with the University of Manitoba. .3 Floor-mounted HVAC equipment shall be installed on concrete housekeeping pads. Pads shall be isolated from the surrounding slab if vibration requirements warrant. .4 The University Architect shall approve locations of mechanical equipment that affects the aesthetics of a building or the campus. Approval procedures shall be discussed with the Physical Plant Department. .5 Emergency generators shall not be installed below grade or in areas where large components cannot be removed from the building. ESTIMATES .1 1.26 Day tanks are to be provided with high level and low level alarm points connected to fire alarm panel. This may be done through the generator control panel but either high or low levels must be indicated as trouble at the main panel. Cost estimates may be requested at certain project intervals and at varying Class levels. The following is a guide to expected accuracy of each Class: .1 Class D: Accuracy 30 to 35% .2 Class C Accuracy 20 to 25% .3 Class B Accuracy 10 to 20% .4 Class A Accuracy 5 to 20 % EXHAUST SYSTEMS .1 Exhaust systems to be interlocked with fresh air supply to ensure complete shut off when fresh air units are stopped. .2 Heat recovery systems to be installed on exhaust systems and energy to be used to preheat and precool incoming ventilation air. .3 Provide exhaust for all photocopier installations either through wall-mounted grilles immediately behind or by direct connection to the photocopier. .4 In each Mechanical Room provide a space exhaust system ducted to outdoors that can be operated whenever welding or other odour/smoke producing activities are conducted in the space. EXISTING INFORMATION February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 11 1.28 1.29 1.30 .1 On request, the design team will be provided resource documents such as building, site plans, and services information where available. Contact the University project representative for more information. .2 The design consultant is fully responsible for the design. If insufficient resource material is available, the consultant must research existing conditions at the project site and generate the data required for a complete and workable design. When significant changes will be made to HVAC or other systems, the consultant will conduct on-site measurements of the system to determine current operating performance. .3 Modifications or extensions to existing systems require thorough analysis and understanding of the impact on the existing operations. The consultant shall insure that the design includes adjustments to the original building systems (including “as-built” drawings with modified performance values shown) to return all adjacent systems to original working capacities. If the original condition cannot be determined, then the consultant must include the services of testing and balancing technicians in his fee to determine the actual status of the existing systems. .4 The University’s chilled water supply is to be considered the primary source for cooling for Fort Garry and Bannatyne campuses. Any design, which does not use the campus chilled water systems as the cooling source, must be reviewed and approved by Physical Plant. FILTER SPECIFICATIONS .1 All air systems shall be provided with filter sections to clean the air and protect system components. .2 Filter installations shall include both Prefilters and Final Filters. .3 Each individual filter section shall be equipped with a magnehelic gauge with ‘clean’ and ‘loaded’ filter settings clearly marked. FLOOR DRAINS .1 Provide floor drains in all Mechanical Rooms, Public Washrooms, and all areas where water is used. Floors are to be sloped at a minimum of 1% toward the drain and drains are to be installed at all low points in the room. .2 Specifications need to include a flood test to be conducted after housekeeping pads are installed to ensure that the floor slopes properly, no water pockets have been created, and that floor drains have been installed at all low points. FIRE EXTINGUISHERS .1 Fire extinguishers are to be provided at all entrances & exits, mechanical, electrical, and elevator machine rooms. .2 Distance between fire extinguishers is not to exceed 75 feet. .3 Built-in wall extinguishers are to be used where possible. .4 Fire extinguishers are to be 10lb ABC, Flag, or Williams with no substitutes. .5 Computer room and Voice/Data room fire extinguishers are to be 5lb CO2 Amerex or Flag with no substitutes. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 12 1.31 1.32 FUME HOOD SYSTEMS .1 Fume hood systems are to be designed and installed in accordance with The University of Manitoba Environmental Health & Safety (EHSO) office’s Controlled Products Standard (CPS). .2 All fume hood exhaust ductwork to be round, with longitudinal seams (not spiral) to reduce the amount of collected material in the exhaust system. .3 Details of all fume hood systems are to be reviewed and be approved by the EHSO prior to construction. GENERAL PRESSURE RELATIONSHIP AND VENTILATION REQUIREMENTS The following table provides the pressure and ventilation requirements for University buildings. University Building Pressure and Ventilation Requirements Area Animal Rooms Auditoriums Classroom Computer Rooms Photo Copier Areas Darkrooms Dining Areas Janitors Closets Kitchens Laboratories Laundry Libraries Locker Areas Lounges Mech/Elect Room Music Rooms Offices PC Labs Washrooms Pressure Minimum Outdoor All Air Exhausted Recirculation Relationship to Air Requirement to Outdoors Permitted ** Adjacent Areas * * * * E Note 1 No Yes E Note 1 No Yes E Note 1 No Yes N Note 1 Yes No N Note 1 Yes No P Note 1 No Yes N Note 3 Yes No N Note 1 Yes No Note 4 Note 1 Note 4 Note 4 N Note 1 Yes No E Note 1 No Yes N Note 1 Yes No N Note 1 No Yes N Note 2 Yes No E Note 1 No Yes E Note 1 No Yes E Note 1 No Yes N Note 3 Yes No * Refer to "Guide for Care and Use of Laboratory Animals" ** Does not apply to units serving this area only. Units may recirculate the air. P,E,N = Positive, Equal, Negative Note 1 Conform to ASHRAE STANDARD 62, Ventilation for Acceptable Air Quality (latest edition). Note 2 Quantity required to maintain a maximum of 10°F above Summer Outdoor Design dry bulb temperatures. Generator Rooms may be allowed to exceed this temperature. Note 3 Transfer from corridors permitted when allowed by code. Exhaust air quantity shall be greater of 2.5 cfm/sq ft or 10 air changes per hour (AC/HR). Note 4 Review specific requirements with the University Project Manager and the University EH&S Office. Requirements may vary. 1.33 HEAT DETECTORS .1 Heat detectors are to be provided in all laboratories. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 13 1.34 1.35 1.36 HOUSEKEEPING ROOMS .1 Housekeeping rooms will typically require the installation of a chemical/cleaner dispenser that is required to be connected to the domestic water system. It is imperative that this is done safely and correctly. .2 Provide a 12mm (½”) domestic cold water connection in the area of each Service Sink complete with a ¼ turn Crane 9202-SS brass ball valve with stainless steel ball and trim. Immediately downstream of the isolation valve adapt to a brass threaded fitting and install a Watts # 7U2-U2 dual check backflow preventer terminated with a hose-end Watts # 8A back siphonage device. All piping from the ball valve forward must remain accessible for testing and visual inspection so the piping is to be surface-mounted with ring hangers. .3 The chemical dispenser company shall provide the necessary hose, fittings and chemical dispensing equipment. HUMIDIFIERS .1 Humidifiers are to be steam-to-steam type, which shall use the building steam supply as the prime energy source. .2 Humidifiers shall be supplied with softened water to reduce maintenance issues. If softened water supply is not available, provide water softener of sufficient capacity. .3 Humidifiers shall be of stainless steel construction and be fully cleanable without removing piping or electrical connections. .4 Units shall control to ±3% relative humidity. .5 No direct injection of building steam supply is permitted for humidification purposes. HVAC EQUIPMENT .1 This section applies to the design and installation of pipe, pipe fittings, valves, piping accessories and equipment for potable and laboratory hot and cold water, heating water, cooling water, steam and condensate, HVAC equipment, sanitary and storm drains, rainwater leaders, compressed air, vacuum and gases. .2 Design piping to allow for ample movement and flexibility for expansion and contraction due to temperature changes. .3 Provide valves to permit isolation of individual pieces of equipment, individual rooms, individual areas, individual floors, individual risers and individual buildings to permit maintenance, alterations repair and replacement work without shutting down entire systems. .4 Provide valves to isolate each piece of equipment and unions to permit removal. .5 Provide thermometers at all locations where fluid mixing or heat transfer occurs. .6 Provide pressure gages at all services entering the building, at pressure reducing valve outlets, pump inlets and outlets, and on other equipment where required for confirming satisfactory operation. .7 Provide pipe sleeves for all piping penetrations through building separations. Provide flood protection in the mechanical rooms and penthouses to prevent water spilled on one February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 14 floor from traveling to the floor below. Coordinate with the Architect to make sure the curbs and sleeves are installed as part of the floor, not installed after the floor is in place. 1.37 .8 Provide adequate access to all equipment requiring maintenance or adjustment. Show building access doors on both the mechanical and architectural drawings so they are properly located for maintenance and appearance. Provide equipment access doors with a minimum size of 600mm x 600mm (24 “x 24”) unless approved otherwise in writing by the Physical Plant Department. .9 Provide access to all equipment with stair, catwalks, and similar fixed access systems. Do not require the need for Genie Lifts or removable ladders unless approved in writing by the Physical Plant Department. Show all maintenance spaces clearly on design drawings. .10 Mount equipment, e.g. fans and pumps, on concrete housekeeping pads secured to structural slab. Size concrete pads larger than equipment. Pad shall extend at least ten times the diameter of the mounting bolts past the equipment. Coordinate with Structural Engineer for final design. Smaller equipment may be wall-mounted instead of padmounted. .11 Provide marine lighting in air unit cabinets to allow unit maintenance and repair without use of flashlights or extension cord lights. Switches to be on exterior of cabinets. .12 Many campus buildings have vibration-sensitive equipment such as electron microscopes. Establish acceptable vibration criteria early in the technical program so that equipment, piping, and ductwork that require vibration isolation can be identified. Provide a table in the design documents, which lists the vibration isolation requirements for piping, equipment, and ductwork. .13 Analyze mechanical system equipment sound levels to control noise transmission. Select all mechanical equipment to meet the noise criteria (NC) requirement of each occupied space. .14 Fiberglass liner inside any portion of ventilation systems is not acceptable. Interior lining to be constructed of impermeable, cleanable, closed-cell liner materials such as IMCOA EPFI ImcoSheet. Face-coated fiberglass insulation is not an acceptable product for any portion of ventilation systems including cross-talk silencers. Do not use liner in the outside air intake duct. Existing HVAC systems with fiberglass liner in good condition may be left in place until the entire duct system is renovated. .15 Reduce fan and air noise by the use of sound attenuators, round or oval ducts, where feasible, instead of rectangular, as well as larger ducts and lower RPM fans. .16 Include a statement in the specifications that all components of the ventilation system (e.g. fan, duct, insulation, sound attenuators, terminal boxes, etc.) must be kept clean and dry as manufactured, delivered, stored and installed before operating the HVAC system. .17 Equipment necessary to maintain building heating shall be connected to emergency power. This includes building control systems and generator controls. .18 Adequate service clearance shall be provided around all equipment. LABORATORY WASTE SYSTEMS .1 The disposal of hazardous wastes (including concentrated acids) into laboratory drainage systems is no longer permitted at the University of Manitoba and has been replaced with February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 15 a very active hazardous waste management program. Because of this hazardous waste management program, there is no longer a requirement for acid interceptors or neutralization tanks to be provided in lab systems. .2 This has been discussed in detail with the City of Winnipeg and approval has been granted to delete these interceptors and neutralizers on a case-by-case basis. .3 To obtain the City’s variance, the appropriate waste management program needs to be suitably identified for each laboratory plumbing project. This identification includes the placing of a brief description on the appropriate design drawings of the actions to be taken to manage hazardous materials, ensure that no chemicals are being disposed of down any drains ant that good engineering practice has been used in the submitted design. .4 The following is an example of a typical note that shall be applied to all lab waste plumbing drawings : The University of Manitoba has adopted a Hazardous Waste Management Program that includes the collection of corrosive and acidic wastes from all laboratories and the safe disposal of these materials through the U of M Environmental Health and Safety Office (EHSO). These materials are regularly collected from each laboratory by EHSO and disposed of to a licensed disposal facility. Because of these effective steps to manage hazardous waste, the City of Winnipeg has permitted this project to be constructed without acid dilution or neutralization tanks. 1.38 1.39 .5 Lab waste systems shall be constructed with drain and vent materials specified in the Master Specification. .6 Lab waste drainage systems shall be piped independently of all other building drainage systems and be connected to the main sewer system within 3 M (10 feet) of the point where it leaves the building. .7 Lab vent systems shall be piped independently of all other vent systems. MANITOBA GREEN BUILDING POLICY .1 All University of Manitoba projects are to be designed and constructed to meet the requirements of the Manitoba Green Building Policy. .2 A copy of the Manitoba Green Building Policy for Government of Manitoba Funded Projects is available at: http://www.gov.mb.ca/est/energy/pdf/green_bldg_policy.pdf MASTER SPECIFICATIONS .1 The University of Manitoba maintains a Master Specification that reflects system and component requirements for many aspects of construction. It is intended to assist design team members during the design process by answering questions about how the University of Manitoba selects materials and systems. This document is offered for design support only and includes no warranty as to correctness or applicability to any particular project. The respective designers are responsible for any result of using University of Manitoba Master Specification information. .2 Specifications are periodically updated as new information is available and in response to the changing needs of the University. The designer must revisit this Master Specification February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 16 during the design process to ensure that up-to-date information is being used. Information is available at: http://www.umanitoba.ca/campus/physical_plant/departments/a&e_masterspecs.html 1.40 MECHANICAL ROOMS .1 Provide a minimum of 2050mm (80”) of clear headroom throughout Mechanical Rooms. .2 All mechanical equipment to be located inside the building except where clearly outdoor equipment. .3 Equipment rooms shall be designed in accordance with all applicable codes and shall be designed to provide adequate maintenance, repair (such as filter, tube and coil pull spaces) and replacement clearances for all equipment. .4 Major equipment items or their components, such as heating and cooling coils, filters, pumps, electric drives, and tube bundles, and their integral appurtenances such as damper motors, control valves, belt drives and guards, shall be so located as to be readily accessible and removable for servicing. .5 Mechanical rooms shall be large enough to allow for equipment maintenance. In addition, adequate access shall be provided for replacement of the largest piece of equipment without removing walls. .6 Clearance shall be adequate to allow maintenance activity without disassembly of any fixed piping, supports, and so forth. Clearance shall be provided around boilers and pressure vessels in accordance with the Department of Labour codes. .7 Equipment rooms shall be provided with an automatic ventilation system capable of removing all heat released within the space. .8 Mechanical room floors shall be sloped at 1% toward floor drains. Floors shall be sloped to ensure drainage to floor drains and no trapped or standing water is allowed to collect. .9 Provide minimum of 75mm (3”) floor drains complete with trap primers. .10 Mechanical rooms and spaces shall be well lit (75 foot-candles at floor). Coordinate this requirement with Electrical Consultant to ensure this is included. .11 Hose bibs and electrical outlets shall be provided in locations required for ease of equipment maintenance. Mechanical rooms shall be provided with at least one set of 20mm (3/4”) hot and cold hose bibbs with backflow preventers in the supply piping. Provide fiberglass service sink at each hose bibb location. .12 All equipment drains, blowdown lines, and such shall be piped to floor drains with an approved air gap fitting. Glycol drains to be collected in suitable receptacles. .13 Equipment rooms shall be located to provide access directly from the building exterior. Where this is not possible, equipment rooms shall be accessed from public spaces. .14 Equipment rooms shall not be located where vibration and/or noise will be objectionable. .15 Mechanical spaces must be accessible by a standard stair or elevator. Ship’s ladders and steep stairs are not acceptable. Doors shall be a minimum of 900mm (36") wide or larger if major equipment needs to be moved through them during maintenance/repair/replacement work. Provide a minimum of 1000mm (40") between adjoining pieces of equipment. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 17 1.41 1.42 .16 Thermally and acoustically insulate mechanical rooms located adjacent to occupied areas. Provide thermostatically controlled ventilation systems to maintain year round space temperatures. .17 Provide a space exhaust system ducted to outdoors that can be operated whenever welding or other odour/smoke producing activities are conducted in the space. .18 To facilitate the cleaning of rooftop equipment, such as condensing units, provide a water service connection for every roof area that can or potentially can accommodate mechanical equipment that will require in-position cleaning. METER INSTALLATIONS .1 Provide a meter connected to Campus DDC system for every utility service (except compressed air and reverse osmosis water). .2 Refer to Energy Advocate (Mike Ferley at 474-6467) for details of individual meter installation. METRIC & IMPERIAL MEASUREMENTS .1 1.43 NOISE CONTROL/ACOUSTIC TREATMENT .1 1.44 1.45 Mechanical drawings and specifications to indicate all sizing and measurements in Metric & Imperial terms and be shown as Metric (Imperial). Acoustic treatment is required in mechanical room walls, floors and ceilings if adjacent areas will be affected by noises generated in the mechanical room. Coordinate construction and interior finishes with Architect. OPERATIONAL CONSTRAINTS .1 Operability, efficiency and maintainability are key elements in the evaluation of the Technical Program and Schematic Design. General use buildings are operated to match occupancy and are normally shut down during nights (10pm to 6am), weekends and holidays. Libraries usually have extended schedules. Laboratory buildings normally run continuously to maintain a safe working environment 24 hours per day. .2 In renovation projects, shutdowns of existing utilities and services may be necessary. These shutdowns may have to occur after normal working hours to prevent interruption of critical operations. Coordinate all shutdowns with the University. Temporary utilities may be necessary to maintain service to critical loads in laboratories and animal care areas and for refrigeration equipment. Factor the impact of long equipment delivery time into the project cost estimate and schedule. PROGRAMMING .1 The majority of University construction is for permanent installation. Design all mechanical systems for an anticipated 40 to 50-year life span before requiring major repairs or replacements. .2 Facility design standards can vary for the Fort Garry campus, the Bannatyne campus and other off-site facilities. Review each project with the Physical Plant Department to determine modifications to the University of Manitoba standards as appropriate. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 18 1.46 .3 The Central Energy Plant (CEP) is located on the south side of the Fort Garry campus and provides utilities to Campus buildings. Mechanical utilities from the CEP include steam, condensate, chilled water, Recuperator heat, and compressed air. Contact Physical Plant for all questions concerning which buildings are or should be on the central utility systems. .4 The Bannatyne Campus is provided with steam and chilled water from Health Sciences Centre (HSC) distribution system. Connection to these services requires coordination with HSC and Physical Plant. .5 The use of rooftop equipment is not permitted except for some specialized exhaust units. Locate mechanical equipment within building mechanical rooms or penthouses. .6 Mechanical rooms need to be large enough to house the equipment and provide adequately sized access pathways for the repair, maintenance, and eventual replacement of the equipment. .7 Equipment access pathways shall be large enough to allow for the removal of coils and other large pieces of equipment. Identify these areas on the design drawings. .8 Where a detailed analysis of the program reveals an inadequate budget to provide the appropriate system design, notify the Project Manager, in writing, of the budget deficiency, the recommended system and its cost, and the alternatives if a budget revision is not provided. Identify and evaluate any necessary alternates early in the design process. .9 Include an evaluation for building system renovation projects, which describes the condition of the building systems, variances from present codes, and identifies spare system capacity or system deficiencies. The design team’s mechanical, electrical, civil, structural, and architectural disciplines should participate jointly in this evaluation. .10 The mechanical infrastructure shall consist of the mechanical rooms, penthouses, shafts and plenum areas. Extra attention must be given to the plenum areas above the corridor ceiling, as they often become the critical space for mechanical and electrical distribution. PHOTOCOPIERS .1 1.47 All photocopier installations shall be equipped with exhaust systems either directly connected to the equipment or including a wall-mounted exhaust grille directly behind the photocopier. Exhaust air shall be directed outdoors. PIPE AND FITTINGS .1 Provide a minimum of two 90-degree changes in direction at each branch connection, particularly in heating systems, with reasonable pipe lengths to allow for pipe movements. .2 Provide pipe expansion loops in place of expansion fittings. .3 Provide unions or flanged connections at equipment for maintenance, repair, and replacement. .4 Provide replaceable bladder type expansion tanks, located at the highest level practical in the system. .5 Design piping circuits so that the circulation pumps cannot be deadheaded. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 19 1.48 1.49 1.50 PUMPS .1 In general, major systems to be provided with duplex pumps with each pump providing 100% of the necessary flow rate with one pump serving as standby. .2 Air unit coils to be equipped with constant volume pumping. Temperature control on coils to be provided by variable fluid temperature control and not by variable flow. .3 Pump motors to be selected to prevent overloading. QUALITY COMMISSIONING .1 The University of Manitoba has implemented a Quality Commissioning Program that involves the review and verification of new construction and renovation projects to ensure all aspects meet the quality standards set by the University. .2 The requirements of the University of Manitoba Quality Commissioning Program are fully described in Specification Section 01810. RECUPERATOR HEAT RECOVERY .1 1.51 ROOF DRAINAGE .1 1.52 1.54 Rooftop equipment areas shall be provided with protective systems to permit safe maintenance & repair operations to take place in high locations. Guardrails and other suitable protective devices are to be installed to ensure personnel remain protected when accessing and working on roof-mounted devices. SITE SERVICES .1 Provide site drainage and catchbasin at all areas where garbage trucks operate. Provide water service in the area to allow exterior areas to be washed down to catchbasin. .2 Provide frost-proof hose bibbs at perimeter of all buildings to allow for landscape watering. SMOKE DETECTORS .1 1.55 Because the University of Manitoba does not wish to store water on any roof, the use of control flow roof drains is not permitted without prior approval of the Physical Plant Department. Roof scuppers are also to be provided to reduce roof flooding potential. ROOFTOP EQUIPMENT BARRIERS .1 1.53 The University of Manitoba recovers boiler energy on the Fort Garry campus through a large Recuperator installation in the Central Energy Plant. This recovered energy is to be used for preheating air and heating domestic hot water. Project systems to be designed to make use of this energy source. This energy source is available at 110ºF during peak operating conditions. Systems to return Recuperator water at no more than 60ºF. Provide smoke detectors in all required areas as well as lounges, lecture theatres, and computer rooms. STANDBY EQUIPMENT FOR CRITICAL AREAS .1 100% standby equipment requirements shall be discussed with the Physical Plant Department for systems serving critical areas such as: February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 20 1.56 1.57 1.58 Laboratories Research buildings Animal rooms .2 Contract documents shall indicate equipment that is intended for standby service. .3 Equipment which is cooled from the building's chilled water system shall have an alternate connection to city water for emergency use. .4 Auto changeover shall be provided for all standby equipment. Changeover shall be alarmed to the Central Control and Monitoring System (CCMS). SOUND PRESSURE LEVEL REQUIREMENTS .1 The sound pressure levels around mechanical and electrical equipment (boilers, fans, pumps, pressure-reducing valves, motors, turbines, elevators, transformers, etc.) in equipment spaces shall not exceed 85 dBA at any point 3 ft from the equipment, with all equipment in the room operating. Sound calculations will be required at completion of installations. The sound criterion applies to the complete operating range of each piece of equipment. Exceptions shall be reviewed by the Physical Plant Department. .2 The maximum room criteria levels for various usage within the building shall be as indicated in Design Guidelines for HVAC System Noise in Unoccupied Spaces, "Sound and Vibration Control," of the latest edition of the ASHRAE Systems and Applications Handbook. .3 Sound pressure level measurements shall be made in accordance with "Sound Testing Procedures" outlined in the latest edition of the ASHRAE Systems and Applications Handbook. Tests shall be made with all equipment operating and space unoccupied. .4 Equipment installed outside the building, at grade, in areaways, attached to walls, and on the roof, such as cooling towers, air conditioning units, refrigerant condensers, fans, exhaust silencers, air intakes, etc., shall comply with all local, city, provincial, and federal sound level regulations (as well as any existing University covenants or agreements with neighbours). .5 When equipment or space sound pressure levels exceed the specified criteria, the Contractor and/or the Design Consultant shall, at no cost to the University, determine the source of the noise and make the necessary corrections to reduce it to the acceptable levels. SPRINKLER SYSTEMS .1 Mechanical drawings shall include concept layout drawings of all sprinkler and fire hose systems. Drawings shall show all mains, distribution piping, fire hose risers, cabinets and sprinkler heads. All other support equipment such as fire department connections, sprinkler head types, and fire pumps shall also be identified. Sprinkler zones, tamper switches, and electrical services shall be coordinated with Division 16. Sprinkler zones shall be identified on the drawings. .2 Libraries and Voice/Data rooms shall be provided with pre-action sprinkler systems. Preaction systems shall also be designed for rooms containing high value material and/or equipment. STANDARD DETAILS February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 21 .1 Physical Plant maintains a library of Standard Details for many construction installations. These have been developed to address operational, maintenance, and replacement issues that are specific to University of Manitoba conditions and systems and are available in both AutoCAD and PDF formats. .2 Standard Details are to be applied where they are appropriate for each project. They can also be modified where needed to suit individual applications with consultation with Physical Plant. .3 Detail Drawings are periodically updated as new information is available and in response to the changing needs of the University. The designer must revisit the Master Details during the design process to ensure that up-to-date information is being applied. .4 Standard Details are available at: http://www.umanitoba.ca/campus/physical_plant/departments/a&e_masterspecs.html 1.59 1.60 1.61 1.62 STEAM SYSTEMS .1 Use two control valves (1/3 – 2/3) for steam control valve applications using over 500 pounds per hour. .2 Control valve bypass lines to be limited in size to provide only 100% design flow at full open to allow for proper manual modulation in the case of a bypass condition. Full line size is not to be used as the bypass size. .3 Use duplex pump receivers to return condensate. .4 All condensate pumps are to be connected to emergency power to ensure continuous heating system operation during power outages. STRAINERS .1 Provide a gate valve and hose-end adapter, with cap, for blowdown on all strainers. .2 Provide strainers ahead of automatic control valves, steam traps, and in main service piping to buildings. SUMP PUMPS .1 Sump pumps are to be submersible-type and be located in sump pits. .2 Sump pit covers and frames to be stainless steel. .3 Each installation is to include duplex pumps operated as lead / lag units on an alternator. .4 Each installation is to be provided with a high water signal to either local alarm in isolated buildings or be connected to the campus DDC system in networked buildings. .5 Where sump pits may receive dumped steam condensate, high temperature sump pumps and level controls need to be provided. VALVES .1 Valves to have stainless steel stems and stainless steel trim. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 22 1.63 .2 Install valves with the stems vertical. When this is not possible, they may be installed rotated but never less than horizontal under any circumstance. .3 Install isolation valves staggered where they are installed in a ganged location so they are completely and conveniently accessible. .4 Install valves with adequate room to permit removal of the bonnet, disk, and trim without removing the valve from the line. VOICE / DATA ROOMS .1 1.64 WARRANTIES .1 1.65 1.66 1.67 1.69 The specifications shall be prepared to include a two-year labour and material warranty for the entire installation, with the exception of requested extended warranty periods. WARM UP LINES .1 Provide steam system warm-up valves around all main isolation valves, control valves and PRV stations to allow for a safe and controlled warm up of steam systems. .2 Bypass lines to be 1” where installed around 3”, 4”, and 6” steam valves. WATER AND DRAIN LINES .1 Any piping containing water and any drainage piping shall not be installed through Electrical or Voice/Data Rooms to avoid damage from potential water leaks. .2 All such piping shall be routed around these rooms in a manner that will prevent water from entering these spaces in the event of a leak. WATER COOLED CONDENSERS .1 1.68 Voice/Data rooms shall be provided with split air conditioning units, preaction sprinkler systems, and temperature sensors connected to alarm at the central Delta station. Temperature sensors/alarms are not required in buildings that do not have Delta control infrastructure in place. Water-cooled condensers shall be dual-circuited with campus chilled water as the primary cooling source and domestic water as backup. The units shall be controlled so that if the chilled water flow stops or the temperature rises too high, the domestic water condensing section shall take over the cooling load. Chilled and domestic water systems shall be independently piped and at no point shall be piped together. WATER SOFTENERS .1 Humidifiers are to be provided with softened water. Provide water softener for individual or ganged humidifiers with sufficient capacity to maintain the humidification water demand. .2 Water softeners to be provided with microprocessor demand control. ZONING .1 Zoning of the systems shall be in accordance with sound engineering judgment relating to varying load conditions, function of space, occupancy schedules, and such. February 27, 2015 University of Manitoba Section 15000 MECHANICAL DESIGN GUIDELINES Page 23 .2 Temperature control zones are to be provided for each individual room. .3 Final zoning shall be discussed at the conceptual design stage with the Physical Plant Department. END OF MECHANICAL DESIGN GUIDELINES SECTION February 27, 2015