ggge20246-sup-0001-suppinfo01

advertisement

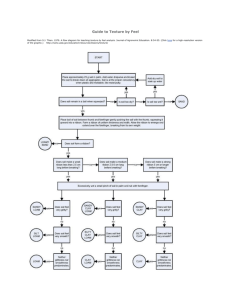

Materials and Methods Samples and sample preparation technique Containers of 0.5 litres of D2O water were placed in a −15°C freezer for one week. The D2O ice was then crushed at -8 °C using a food processor. The crushed ice was sieved and a size fraction between 1 and 1.68 mm was used for the preparation of the final samples. The ice powder was filled into custom made cylindrical moulds with dimensions of 2.5 cm diameter and 7 cm height. D2O water (approx. 5 ml), close to the freezing point, was added to the mould with a syringe while constantly stirring the ice. Finally, the ice was compressed using a piston with holes allowing excess water to escape. The excess water (1-3 ml) was removed using a syringe. The mould was put immediately into a −15°C freezer and the sample were removed from the mould after one to two hours and then stored in the −15°C freezer four 4 weeks. Deformed samples were stored in a -80 °C freezer and any handling was performed at -20 °C or colder to ensure that no annealing or recovery took place. Hence, final thin section derived microstructures as well as final full textural data represent the final deformation stage of each experiment. Full texture analysis: Details For full texture analysis three full pole figures of the indices (100), (002) and (101) were obtained. The pole figures were measured on a regular 5° mesh by using 5° steps in the goniometer axes and . To improve grain statistics an additional rocking in the range of 5° around ω axis was applied to the goniometer during measurements still keeping the resolution of measurements within 5°. In-situ Neutron Diffraction measurements: partial pole figures and grain size The instrument sample table allows the placement of either a load-frame for in-situ deformation analysis or a goniometer used for the texture analysis after deformation. The load frame or sample orientation can be changed allowing alignment at a certain angle with respect to the scattering vector that is defined by the incident and scattered neutron beams (Fig. S1). The beam geometry, load frame dimensions and detector size allowed a change of angle in the range ±39° from the direction of the applied load. In the coordinate system of a sample it provides a cross section of the central part of pole figure, with polar angle also ranging over ±39°, and therefore this can be considered as a partial pole figure measurement assuming cylindrical symmetry of the crystallographic texture (Fig. S1). For the acquisition of the partial pole figure during deformation, the platform was moving in 1° steps. At each step, the load-frame stops and the detector acquires a 2D diffraction pattern of the diffracted neutrons during 10 s. To cover one partial pole figure scan, with a range of ±39° in 1° steps, took 35 minutes. For the medium strain rate experiments it was sufficient to make resolution in strain scale of ~1%. For fast experiments to keep the same strain resolution the time per cycle was reduced to 20 minutes by increasing steps size to 2°. For representation of the partial pole figures, the points at the same ± angle from the compression axis were averaged and additionally binned to 5° intervals. The resultant pole figure partial cross sections with angle from 0° to° is shown as in Fig. 2. In addition to the texture development, the partial pole figure was used to derive the mean grain size of the sample. The principle of the approach is to look at intensity oscillation of the measured diffraction pattern: an infinite number of grains will give perfect diffraction peaks without any fluctuations while a small number of grains N will give large statistical fluctuations in comparison The observed diffraction integrated intensity is a statistical quantity proportional to the neutron beam flux and number of crystallites which are in reflection condition i.e. comply with Bragg’s law. The number of crystallites n is a random quantity and it is characterized statistically by the expectation of grain complying with the Bragg’s law. Therefore, n needs to be corrected according to the developing texture. The calculation of the influence of the developing texture is based on information in the partial pole figure. Once this is achieved, individual grain numbers evaluated for a series of particular angular position and hkl reflection were averaged to produce a reliable estimate of the numbers of grains in a sample and consequently the mean grain size. Statistical analysis showed that mean grain size estimate is accurate within 5% error. Comparison with optically derived grain sizes of samples analysed after deformation confirm grain size estimations by the above mentioned neutron diffraction analysis method. Quantitative analysis of full texture through decomposition into texture components in vol% In order to trace quantitatively the texture evolution during progressive deformation (Fig. 2F) the texture was decomposed into two main components using the following method. The cylindrical symmetry (C∞) of the loading process and textures developed in samples during loading allows us to analyses preferred orientation in terms of fibre texture components. The full texture model consisting of the random (background) component and one/two Gaussianshape components was proven to be describing orientational distributions the same as any other texture reconstruction methods (Harmonic or WIMV). This then allowed determination of the volume fraction of a component within 0.5% accuracy. Each Gaussian-shape component is described by a few parameters, intensity (%), width (°) and the crystal direction azimuthal angle (°). Since only intensity changes significantly, the information on preferred orientation can be represented as the relative volume fraction of the two texture components identified.