3.9.3

advertisement

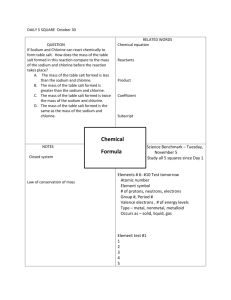

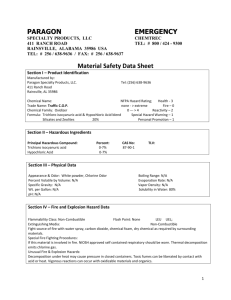

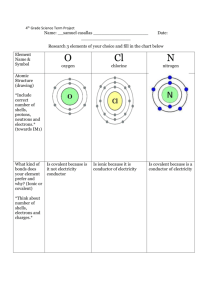

Cranbrook Fire & Emergency Services Operational Guidelines HAZARDOUS MATERIALS RESPONSE – CITY OWNED PROPERTY CHLORINE OG# 3.9.3 Date of Last Revision: January 15, 2013 Purpose: To provide a uniform safe approach to conducting emergency responses to City owned facilities with known hazardous materials on site. Scope: All Cranbrook Fire & Emergency services personnel Policy: It is recognized that hazardous material incidents possess unique hazards related to fire extinguishment, safety, and remediation. CF&ES personnel will utilize the following procedures as a general guideline. Due to the complex nature of hazardous materials incidents alternative actions may be necessary and required. Procedure: Notify the Deputy Director or Director of the incident. Chlorine Properties Chlorine STEL .5 parts per million for 15 minutes or .3 parts per million for 8 hours, IDLH 10 parts per million. Chlorine is a strong oxidizer. PPE Canutec recommends that level “A” encapsulating suits are used for entry involving chlorine. CF&ES uses Dupont Tychem TK with SCBA for our level “A” selection with tingly boots. All seams must be taped using “chemtape” on ankles and zippers. For extreme life safety situations the use of fire fighting bunker gear and SCBA is permitted. The rescuer should not be exposed to chlorine for longer than 10-15 seconds. If a turnout gear rescue is conducted the rescuer must be stripped of clothing and decontaminated in soap and water immediately. Note: the rescuer risks minor burns and irritation to the skin. Entry of the Hazard Zone The Entry team will utilize an M-40 gas detector and chlorine badge detector. Both will be calibrated and zeroed prior to entry at normal atmospheric conditions, away from the incident. Once the response team has donned PPE, determine the location of the leak. Page 1 of 5 HAZARDOUS MATERIALS RESPONSE – CITY OWNED PROPERTY CHLORINE continued… Leak Detection Using an ammonia bottle, spray the ammonia vapor around the area of the cylinder and look for the white smoke to form. Avoid spraying liquid, as this encourages corrosion around the leak. Check the fittings and connections (including the chlorinator). This is where the majority of leaks occur. Once the leak has been located, determine how the leak is going to be contained. Containment If a leak develops around the valve, first open and close the valve stem. It is possible that there are metal filings or dirt that may be lodged on the valve and valve seat. Opening and closing the valve can dislodge the material. The valve and valve seat is a metal to metal junction and can be sticky, be firm when tightening the valve. The valve can be opened by striking the chlorine wrench with the heel of the hand, don’t use a wrench extension. If the leak is still present tighten the packing nut, do not over tighten. This will seal off any leaks that occurring around the packing. If the leak is from the valve inlet threads, carefully tighten the valve. Do not over tighten as the leak could be as a result of the corrosion and further damage may occur to the valve or the container. If the leak is from the inlet threads of the fusible plug tightened the plug, exercise caution. Consider the use of the “A” Kit to isolate the leak. Fire Fighting Procedures Evacuate area endangered by gas. Stay upwind; keep out of low areas. Wear positive pressure breathing apparatus and full protective clothing. Move container from fire area if you can do so without risk. Spray cooling water on containers that are exposed to flames until well after fire is out. If it is necessary to stop the flow of gas, use water spray to direct escaping gas away from those effecting shut-off. Water only; no dry chemical, CO2 or Halon®. Contain fire and let burn. If fire must be fought, water spray or fog is recommended. Page 2 of 5 HAZARDOUS MATERIALS RESPONSE – CITY OWNED PROPERTY CHLORINE continued… Do not get water inside containers. Move containers from fire area if you can do it without risk. Damaged cylinders should be handled only by specialists. (Brenntag Canada services and supplies the chlorine that is found in the rec plex. 1- (403)-720-5650 located in Calgary AB.) Substance does not burn but will support combustion. Vapors from liquefied gas are initially heavier than air and spread along ground. These are strong oxidizers and will react vigorously or explosively with many materials including fuels. May ignite combustibles (wood, paper, oil, clothing, etc.). Some will react violently with air, moist air and/or water. Cylinders exposed to fire may vent and release toxic and/or corrosive gas through pressure relief devices. Containers may explode when heated. Ruptured cylinders may rocket. Will not burn, but most combustible materials will burn in chlorine as they do in oxygen; flammable gases will form explosive mixtures with chlorine. Rec Plex – Chlorine The source of a chlorine leak at the Rec Plex would be located on the Delta side (17th Ave South) in the chlorine room (Door #15). The chlorine room has a CL monitor which will activate alarms at 0.5ppm. When this occurs the ventilation fan automatically activates and vents product through a stack on the roof (south on the Delta side). The chlorine room is self contained. If a spill or leak is to occur, the rink staff is notified by audible and visual alarms. Rec plex employees then determine if the complex needs to be evacuated. If needed, lifegaurds will evacuate the pool facility while the maintenance crew will determine the cause of the alarm. Page 3 of 5 HAZARDOUS MATERIALS RESPONSE – CITY OWNED PROPERTY CHLORINE continued… Once a chlorine leak is confirmed the maintenance crew will contact CF&ES to assist with confinement/containment. CF&ES will respond with required Hazmat equipment and PPE. Additional man power may be called in to perform service or repair at the discretion of the IC. Approach on the Delta side. Note the wind direction. The chlorine room emergency vent is located near the wind sock; this will provide an indication as to what direction the vented chlorine vapor will be travelling. Stage near entrance #15. The outside door labeled “Chlorine” leads directly to the room where the leak would occur. Do not make Entry or open this door without proper PPE. The double door on the left is likely safe to enter (monitor for chlorine with gas badge and M40) and provides a viewing window that looks into the contained chlorine room. This provides the opportunity to view the chlorine sensors that will show chlorine concentrations measured in ppm inside the chlorine room. It also provides a visual assessment of the chlorine cylinders through a sealed window. Water Treatment Plant – Chlorine Plant Chlorine leaks at the plant will contaminate the entire building; there is no safe area within the building sealed off from the chemical. The chlorine plant has an unmonitored chlorine monitor which activates an internal alarm at .5 PPM. Leaks would be discovered during daily chlorine plant checks. Notification of a leak is provided by flashing amber lights. One is located on a mast on the bravo/charlie corner of the building and another above the main entrance. The chlorine monitor is located inside the structure, near the main entrance. There is no automatic exhaust system; gas will collect within the structure. Once a leak is detected Public Works will call CF&ES to contain the leak and clear the building of gas. Page 4 of 5 HAZARDOUS MATERIALS RESPONSE – CITY OWNED PROPERTY CHLORINE continued… The IC will need to call in adequate resources to deal with the incident and maintain the capacity for emergency response within the response area. EMS should be requested for standby and be staged well outside of the warm zone. Access to the site is through yellow locked gates located at the south end of the City water reservoir. The City pad lock keys are available in all CF&ES apparatus lock boxes. Note wind direction, confirm alarm activation (flashing amber lights) and observe general conditions from the hill top approach. Utilize monitors and approach slowly to identify a safe staging area. 100lbs CL bottles are utilized at the plant and it is likely a leak can be isolated by closing valves or utilizing the “A” Kit. Reference: http://www.phoenix.gov/fire/vol2index.pdf, Phoenix Fire Department, Standard Operating Procedures. Retrieved December 15, 2009. Cranbrook Fire & Emergency Services Incident Action Plan (IAP) Also OG: Incident Accountability, 2.4.1 Incident Command, 2.4.2 Public evacuations, 3.2.9 Staging, 3.3.11 Hazardous Materials Response - General, 3.9.1 X W a yn e Price D ire cto r o f F ire & E m e rg e n cy S e rvice This OG replaces: Implementation Date: May 28, 2012 Page 5 of 5

![[1] - Boswellsgmt](http://s3.studylib.net/store/data/006603407_1-fadfbce8d94050a9fb3c38a07d86e8ee-300x300.png)