Safe Work Procedure - Faculty of Medicine

advertisement

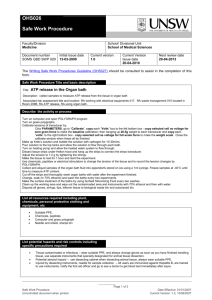

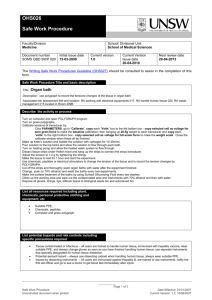

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS GBD SWP 029 School/ Divisional Unit School of Medical Sciences Initial Issue date 13-03-2009 Current version 1.0 Current Version Issue date 20-04-2010 Next review date 20-04-2013 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Mini organ bath Title: Description: use polygraph to record the tensions changes of the tissue in organ bath, measure mediators such as ATP that are released from tissue under different conditions/stimulations. Associated risk assessment title and location: RA working with electrical equipments 017, RA waste management 015 located in Room 209B. Describe the activity or process Turn on computer and open POLYGRAPH program. Turn on grass polygraphs. Calibrate tensions of transducer using weights and powerlab. Make up Kreb’s solution and bubble the solution with carbogen for 10-30mins. Turn on the water-bath. Place mini organ bath pump tubes into flask containing the Krebs and turn on pump to allow the Krebs to flow around the system. Record the temperature, flow rate and bubble time (how long the bubble takes to flow though the system and reach the mini bath. Adjust tubing length, water-bath temperature as necessary so that the flow rate is equal in all channels and the temperature of the Krebs is 37°C on reaching the mini bath. Dissect tissue strips under Helton hood and hang up the strips in the mini organ baths. Adjust the tension to 1.0 g by tightening the strings. Make the tissue to rest for 1 hour and start the experiment. Use chemicals, mechanical or electrical stimulators to change the tension of the tissue and to record the tension changes by POLYGRAPH. Collect the Krebs after it passes through the tissue and store for analysis and assaying later. Cut off the strips and thoroughly wash mini organ baths with water after the experiment finished by flushing the system. Clean up the working area and wipe out the contaminated area and instruments with 70% ethanol and then with water. Dispose all gloves, strings, tips, leftover tissue to biological waste bin and autoclaved bin. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Suitable PPE, Chemicals, peptides Computer and grass polygraph List potential hazards and risk controls including specific precautions required Tissue contaminated or infectious – all users wear suitable PPE, and always change gloves as soon as you have finished handling tissue, use separate instruments that specially designated for anima tissue dissection. Potential aerosol hazard – always use dissecting cabinet when handling human tissue, always wear suitable PPE. Injured by dissecting instruments – All users are immunized against Hepatitis B, are trained to use instruments, notify the first aid officer and go to see a doctor to get blood test immediately after injure. ___________________________________________________________________________________________________________ ___________ Page 1 of 2 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List emergency shutdown instructions Shut all electrical equipment off at power point in case of emergency. List clean up and waste disposal requirements Not applicable List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Code of Practice for the Labeling of Workplace Substances Australian Standard AS2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. Australian Standard AS2243.7-1991. Safety in laboratories. Part 7: Electrical Aspects. Safe Work Procedure Form (OHS026) Supervisory approval, training, and review Supervisor: Prof E Burcher Signature: Plant custodian: Signature List competency required – qualifications, certificates, licensing, training - e.g. course or instruction: SWP review date: 20-04-2013 Responsibility for SWP review: Fei Shang ___________________________________________________________________________________________________________ ___________ Page 2 of 2 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007