dimension stone industry status in uganda

advertisement

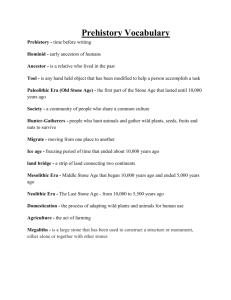

DIMENSION STONE INDUSTRY STATUS IN UGANDA Vincent Kato Dimension stone industry is still in its infancy and has not developed much in Uganda. There is virtually no organized mechanized local production at present or raw block export. This is despite the abundance of raw materials ascribed to varied Ugandan metamorphic and igneous geology. Although the market is rather small, nevertheless it is growing rapidly. Raw material sources include vast amounts of massive hard magmatic, volcanic, metamorphic and massive soft sedimentary rocks all over Uganda. Some of these rocks have been exploited at artsanal small-scale for flooring, cladding, paving and as building stone. Photo: Staircase made of granite tile M/s Premier Stone Ltd has shown interest in the industry and has accordingly applied for Exploration Licenses in three areas. The major problem hindering the industry has been the high initial capital investment and maintance costs of extractive and processing machinery. High electricity tariffs and labor charges has scared away the would be potential investors. A few companies are importing granite and marble slabs from India, Kenya, Zimbabwe, China, Italy and Egypt. These are involved in producing tiles, tabletops, kitchen tops and reception tops. There is a growing demand of dimension stone products due the ever-increasing growth rate in the construction industry (8.5% annually). A huge market exits in the Democratic Republic of Congo, Rwanda and Southern Sudan, which create an incentive to any potential investor in the industry. Photo: Wall cladded with granite blocks Uganda is endowed with hard massive rocks like granites (pink, grey, reddish and greenish varieties), banded and foliated gneisses, migmatites gabbros, quartzite amphibolites, diorites well as massive soft rocks like marble (pink and white), limestone, travertine, sandstone, dolomite. Others include slabby rocks like slates, flagstone, laterite and volcanic tuffs. These are abundant are currently locally quarried for construction aggregates, building stones, slates (flooring and cladding), cement and lime manufacture. The country boosts of huge massive deposits of metamorphic and igneous rocks. These are all near major high ways and population centers. Photo: granite blocks for pavers A few firms have made failed attempts to develop the dimension stone industry in Uganda due to high initial capital investment and operating costs anticipated. Currently Ms Uganda Marble and Granite Ltd, Granite Homes Ltd and Millennium Marble (2000) Ltd are importing granite and marble slabs from India, Kenya, China, Zimbabwe and Egypt to supply the local market. These firms deal in tiles, kitchen tops, counter tops, vanity tops, tabletops, ornaments, and pavers. Among the Firms supplied with construction materials include Bank of Baroda, Kabira International School, and Serena Hotel. About 50,000 square meters of both granite and marble slabs are imported every year. M/s Premier Stone Ltd (Stone World Ltd) has applied for Exploration Licence to carry out a feasibility study of developing Dimension stone industry in Uganda. In their study they hope to look at market assessment, technological feasibility, social desirability, ecological soundness, production assessment and financial modeling. They hope to use locally fabricated machinery, which they hope are cheap, affordable and simple to maintain. They have carried out tests on granites at laboratory scale and produced good polished sections. Photo: Bathroom top made of marble. About 26 granites in western and eastern Uganda have been sampled. Ms Premier Stone Ltd has carried out a research on the potential of using Ugandan slates as roofing slates. Ms Industrial Minerals Ltd imported block-cutting machinery and tried it on Kisoro volcanic tuffs but has since abandoned the cutting due to other commitments. Others activities in dimension stone industry include local production of building stones, at a local small-scale from welded volcanic tuffs in Fort Portal, Bunyaruguru, Kapchorwa, Kabale and Kisoro. A number of houses are build from blocks crudely shaped from welded tuffs. Others include slates and granite blocks extracted for flooring, cladding and as building stones for small-scale local market. Photo: Brick kiln chambers at Butema (Hoima) made of laterite blocks A number of problems have hindered the development of dimension stone industry in Uganda. These include among others the high investment and maintenance costs of extractive and processing machinery. European machinery as well as Chinese and Indian machinery has proved too costly for local Ugandan investors. The high investment and maintenance costs raise production costly in addition to high electricity tariffs and production labor. It is claimed that it is sometimes cheaper to import slabs from India or China than extracting and processing dimension stone in Uganda. Other problems encountered include lack of unique aesthetic varieties to compete with varieties already on market and the uncertainty of market availability. Lack of trained manpower and competition from existing dimension stone producing firms has hindered the industry. Photo: Tile from gneiss and gabbro Locally available, simple and affordable alternative improved technology will solve the dimension stone extracting and processing technology problems. The problem of high costs of extractive and processing machinery can be overcome by improvising and fabricating this machinery locally, which need low investment and operating costs. This has been done successfully in Kenya and it is a success story to tell about. Experienced personnel from other African countries cannot be avoided. Hi-Tech Granite Industries Ltd succeeded in fabricating cutting and polishing machines. These manual machines are effective and less costly, can be easily operated and repaired. The company has manual and automated machines but not highly sophisticated. Photo: Granite seats A tile-cutting machine was estimated to have costed about 350,000 K Shs while another was costed at about 150,000 K shs. These have simple operation and maintenance. An automated polishing machine would cost about 300,000 K shs while manual polishing machine would cost about 50,000 K shs. Motors are costing not more than 10,000 K shs. The company buys blades and fixes diamond bits. This copped with simple extraction using a compressor and wedges makes production cheaper. Blocks from the quarry are loaded using pulleys. There is a lot waste produced during the extraction and processing of dimension stone products. A waste utilization scheme would be incorporated in the dimension stone industry to boost the income generating capacity of the firm. Magnum Engineers Ltd (Kenya) can fabricate the processing machinery at 3,800,000 K shs including installation and commissioning. Producing dimension stone using locally available material, using simple technology at low cost will help in reducing import expenditure and create new local job opportunities. New labor skills will be imported and the government will broaden its tax base. This will contribute to the modernization of the building industry. There is a tax waver for mining and quarrying machinery.