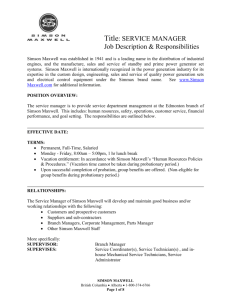

Manufacturing Manager

advertisement

Manufacturing Manager Simson Maxwell was established in 1941 and is a leading name in the distribution of industrial engines, and the manufacture, sales and service of standby and prime power generator set systems. Simson Maxwell is internationally recognized in the power generation industry for its expertise in the custom design, engineering, sales and service of quality power generation sets and electrical control equipment under the Simmax brand name. See www.Simson Maxwell.com for additional information. POSITION OVERVIEW: Reporting to the VP Engineering & Production, this position is responsible to effectively manage all resources involved in the assembly of custom built Generator sets, Control Assembly products, overall responsibility for managing the production process. In addition this position is responsible for supporting customer, quality and employee objectives by: maintaining manufacturing timelines, developing and implementing plans to enhance productivity, supporting cost improvement objectives and nurturing employee development and drive the implementation within the department of key corporate initiatives Simson Maxwell product standards. EFFECTIVE DATE: As Soon As Possible TERMS: Permanent, Full-Time, Salaried Monday - Friday, 7:30 am –4:00 pm, 1/2 hr lunch break Vacation entitlement: In accordance with Simson Maxwell’s “Human Resources Policies & Procedures.” Eligible for participation in group benefits program THE ROLE: Maintains and promotes a clean and safe work environment Develops, evaluates and improves manufacturing methods Utilize Lean tools to improve all manufacturing areas Confers with planning and design staff concerning product design and analyzes and plans work force utilization, space requirements, and work flow, and designs layout of equipment and work space for maximum efficiency, tooling to ensure efficient production methods Confers with vendors to determine product specifications and arrange for purchase of equipment, materials, or parts, and evaluates products according to specifications and quality standards Estimates production times, staffing requirements, and related costs to provide information for management decisions Confers with management, engineering, and other staff regarding manufacturing capabilities, production schedules and other considerations to facilitate production processes Applies statistical methods to estimate future manufacturing requirements and potential Ensures compliance with cost controls Maintains staff by recruiting, selecting, orienting and training employees; developing personal growth opportunities Maintains quality service by establishing and enforcing organization standards Resolves personnel problems by analyzing data; investigating issues; identifying solutions; recommending action Essential Functions: Supervise the administration of Simson Maxwell and Production Plant policies/guidelines to ensure consistent and uniform application. Maintain effective intra, as well as inter departmental communications, as required. Establish, monitor and maintain active communications between all levels of plant personnel to assure a positive work environment. Direct the development and implementation of cost, productivity and strategic manufacturing programs consistent with plant objectives. Analyze department capacity restrictions and develop alternative plans to improve methods and layouts, as well as recommend new equipment expenditures to align capacity with plant objectives. Identify metrics for key business drivers and reinforce knowledge of them throughout the assembly operation. Implement process improvement, cost reduction and quality improvement processes . Effectively manage the departmental budget, including tracking of capital equipment. Maintain departmental tooling and equipment, including the provision of new/replacement hand tools etc. Manage department manpower and capacity planning. Partner with Human Resources on recruitment (assessment and selection) for entry level openings and promotional opportunities within the department. Communicate and enforce product quality standards and review team/individual quality performance through the analysis of relevant data and metrics. Provide on-going mentoring, coaching and development of direct reports to instill a team-focused and quality culture within the department. Complete annual performance evaluation/mid-year progress reviews for all direct reports. Identify opportunities for development and support employees through on-going coaching/counseling, as required. Fully deploy performance management system, Achieving Performance Excellence for Manufacturing (APEX-Mfg), within the department meeting all requirements and deadlines. Manage the Survey feedback process within the department. Provide leadership with management system for environment, health, safety and security (MESH). Maintain a positive commitment to the prevention of pollution and protection of the environment, work instructions and other operational controls. Provide leadership and actively participate in the quality improvement process. Perform other duties, as required. Basic Qualifications (Including Educational Requirements) Basic Qualifications: Technical Degree/ Diploma or Post Secondary Education Diploma followed by number of years technical experience is required. Minimum 5 years of experience in technical manufacturing or operations is required (heavy manufacturing involving engines and generators preferred) Minimum 2 year of supervisory experience in manufacturing process is required. Must be authorized to work in Canada without company sponsorship. Preferred Qualifications: Experience in a manufacturing environment preferred. Excellent communication, interpersonal and organizational skills. Ability to multi-task and work in a fast paced environment. Strong analytical aptitude and complex problem solving skills. Intermediate knowledge of MS Office. Effective time management and project management skills. Strong commitment to customer service.