Chapter_9-11262012

advertisement

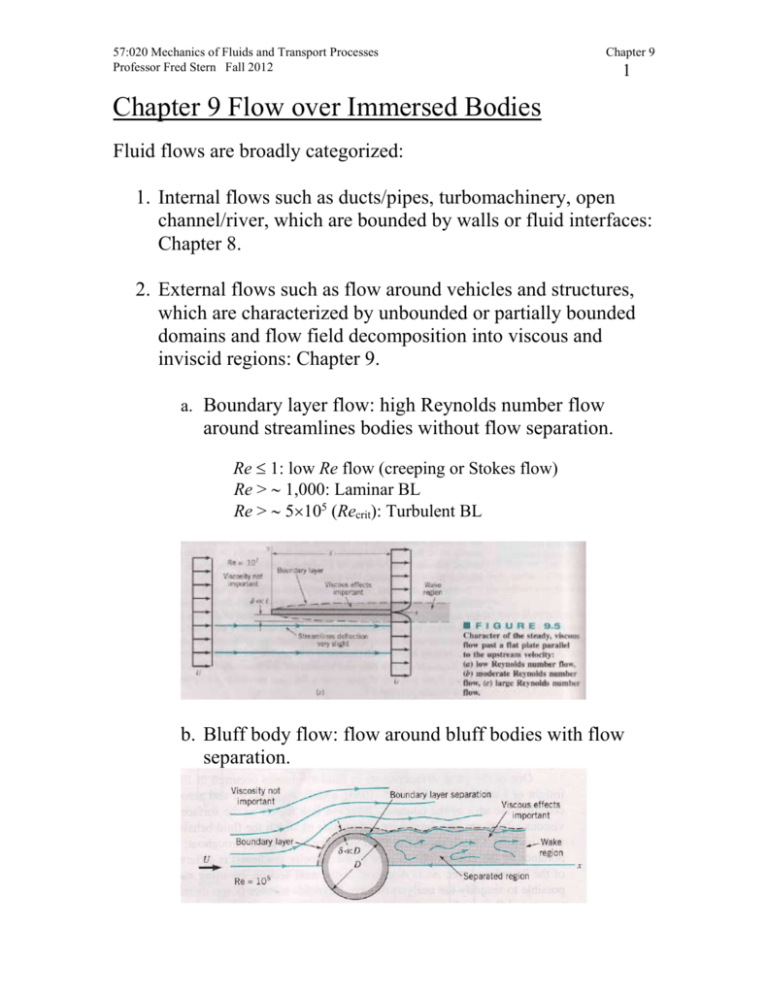

57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 1 Chapter 9 Flow over Immersed Bodies Fluid flows are broadly categorized: 1. Internal flows such as ducts/pipes, turbomachinery, open channel/river, which are bounded by walls or fluid interfaces: Chapter 8. 2. External flows such as flow around vehicles and structures, which are characterized by unbounded or partially bounded domains and flow field decomposition into viscous and inviscid regions: Chapter 9. a. Boundary layer flow: high Reynolds number flow around streamlines bodies without flow separation. Re 1: low Re flow (creeping or Stokes flow) Re > 1,000: Laminar BL Re > 5105 (Recrit): Turbulent BL b. Bluff body flow: flow around bluff bodies with flow separation. 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 2 3. Free Shear flows such as jets, wakes, and mixing layers, which are also characterized by absence of walls and development and spreading in an unbounded or partially bounded ambient domain: advanced topic, which also uses boundary layer theory. Basic Considerations Drag is decomposed into form and skin-friction contributions: CD p p n î dA t î dA w 1 2 S S V A 2 CDp Cf 1 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 CL Chapter 9 3 p p n ĵ dA 1 2 S V A 2 1 t << 1 c Cf > > CDp streamlined body t 1 c CDp > > Cf bluff body Streamlining: One way to reduce the drag reduce the flow separationreduce the pressure drag increase the surface area increase the friction drag Trade-off relationship between pressure drag and friction drag Trade-off relationship between pressure drag and friction drag Benefit of streamlining: reducing vibration and noise 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 4 Qualitative Description of the Boundary Layer Flow-field regions for high Re flow about slender bodies: 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 5 w = shear stress w rate of strain (velocity gradient) = u y y 0 large near the surface where fluid undergoes large changes to satisfy the no-slip condition Boundary layer theory and equations are a simplified form of the complete NS equations and provides w as well as a means of estimating Cform. Formally, boundary-layer theory represents the asymptotic form of the Navier-Stokes equations for high Re flow about slender bodies. The NS equations are 2nd order nonlinear PDE and their solutions represent a formidable challenge. Thus, simplified forms have proven to be very useful. Near the turn of the last century (1904), Prandtl put forth boundary-layer theory, which resolved D’Alembert’s paradox: for inviscid flow drag is zero. The theory is restricted to unseparated flow. The boundary-layer equations are singular at separation, and thus, provide no information at or beyond separation. However, the requirements of the theory are met in many practical situations and the theory has many times over proven to be invaluable to modern engineering. 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 6 The assumptions of the theory are as follows: Variable u v x y order of magnitude U <<L O(1) O() 1/L O(1) 1/ O(-1) 2 2 = /L The theory assumes that viscous effects are confined to a thin layer close to the surface within which there is a dominant flow direction (x) such that u U and v << u. However, gradients across are very large in order to satisfy the no slip condition; thus, >> . y x Next, we apply the above order of magnitude estimates to the NS equations. 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 7 2u 2u u u p u v 2 2 x y x x y 1 1 -1 2 1 -2 2v 2v v v p u v 2 2 x y y x y 1 1 2 elliptic -1 u v 0 x y 1 1 Retaining terms of O(1) only results in the celebrated boundary-layer equations u u p 2u u v 2 x y x y p 0 y u v 0 x y parabolic 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 8 Some important aspects of the boundary-layer equations: 1) the y-momentum equation reduces to p 0 y i.e., p = pe = constant across the boundary layer edge value, i.e., from the Bernoulli equation: inviscid flow value! 1 2 p e U e constant 2 p e U e U e i.e., x x Thus, the boundary-layer equations are solved subject to a specified inviscid pressure distribution 2) continuity equation is unaffected 3) Although NS equations are fully elliptic, the boundary-layer equations are parabolic and can be solved using marching techniques 4) Boundary conditions u=v=0 y=0 u = Ue y= + appropriate initial conditions @ xi 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 9 There are quite a few analytic solutions to the boundarylayer equations. Also numerical techniques are available for arbitrary geometries, including both two- and threedimensional flows. Here, as an example, we consider the simple, but extremely important case of the boundary layer development over a flat plate. Quantitative Relations for the Laminar Boundary Layer Laminar boundary-layer over a flat plate: Blasius solution (1908) student of Prandtl u v 0 x y Note: p =0 x for a flat plate u u 2u u v 2 x y y u=v=0 @y=0 u = U @y= We now introduce a dimensionless transverse coordinate and a stream function, i.e., y U y x xU f 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 u U f y y v Chapter 9 10 f u / U 1 U f f x 2 x Substitution into the boundary-layer equations yields ff 2f 0 Blasius Equation f f 0 @ = 0 f 1 @ = 1 The Blasius equation is a 3rd order ODE which can be solved by standard methods (Runge-Kutta). Also, series solutions are possible. Interestingly, although simple in appearance no analytic solution has yet been found. Finally, it should be recognized that the Blasius solution is a similarity solution, i.e., the non-dimensional velocity profile f vs. is independent of x. That is, by suitably scaling all the velocity profiles have neatly collapsed onto a single curve. Now, lets consider the characteristics of the Blasius solution: u vs. y U v U vs. y 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 5x Re x U x Re x Chapter 9 11 value of y where u/U = .99 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 12 U f (0) w 2x / U cf i.e., see below 2 w 0.664 2 Re x x U : Local friction coeff. L b Cf c f dx 2c f ( L) bL 0 1.328 Note: = 𝑏 = plate width Re L 𝐿 = plate length Wall shear stress: w 0.332U 32 x : Friction drag coeff. UL or w 0.332 U x Re x Other: u x * dy 1.7208 displacement thickness 1 U Re 0 x measure of displacement of inviscid flow due to boundary layer u u x 1 dy 0.664 U U Re x 0 momentum thickness measure of loss of momentum due to boundary layer * H = shape parameter = =2.5916 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 13 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 14 Quantitative Relations for the Turbulent Boundary Layer 2-D Boundary-layer Form of RANS equations u v 0 x y u u pe 2u u v 2 u v x y x y y requires modeling Momentum Integral Analysis Historically similarity and AFD methods used for idealized flows and momentum integral methods for practical applications, including pressure gradients. Modern approach: CFD. To obtain general momentum integral relation which is valid for both laminar and turbulent flow For flat plate or for general case momentum equation (u v) continuity dy y 0 w 1 d dU c 2 H f dx U dx U 2 2 dU 0 flat plate equation dx dp dU U dx dx 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 15 u u 1 dy U U 0 momentum thickness * H shape parameter u 1 dy U 0 * displacement thickness Can also be derived by CV analysis as shown next for flat plate boundary layer. Momentum Equation Applied to the Boundary Layer Consider flow of a viscous fluid at high Re past a flat plate, i.e., flat plate fixed in a uniform stream of velocity Uiˆ . Boundary-layer thickness arbitrarily defined by y = 99% (where, 99% is the value of y at u = 0.99U). Streamlines outside 99% will deflect an amount * (the displacement thickness). Thus the streamlines move outward from y H at x 0 to y Y H * at x x1 . 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 16 Conservation of mass: H H V ndA =0= 0 Udy 0 udy CS Assume incompressible flow (constant density): UH udy U u U dy UY u U dy Substituting Y Y Y 0 0 0 Y H * defines displacement thickness: u * 0Y 1 dy U * is an important measure of effect of BL on external flow. Consider alternate derivation based on equivalent flow rate: δ δ* Lam=/3 δ* Turb=/8 * 0 Udy udy Inviscid flow about δ* body Flowrate between and of inviscid flow=actual flowrate, i.e., inviscid flow rate about displacement body = viscous flow rate about actual body * * u Udy Udy udy 1 0 0 0 0 U dy * w/o BL - displacement effect=actual discharge For 3D flow, in addition it must also be explicitly required that * is a stream surface of the inviscid flow continued from outside of the BL. 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 17 Conservation of x-momentum: F x D uV ndA U Udy u udy H Y 0 0 CS Y Drag D U 2 H 0 u 2 dy = Fluid force on plate = - Plate force on CV (fluid) Again assuming constant density and using continuity: Y H 0 u dy U D U 2 Y 0 Y x u / Udy u dy w dx 2 0 0 u Y u 1 0 U U dy 2 U D where, is the momentum thickness (a function of x only), an important measure of the drag. 2D 2 1 CD c f dx 2 U x x x 0 x cf w 1 U 2 2 d c f dx 2 cf Per unit span d d xCD 2 dx dx w U 2 d dx Special case 2D momentum integral equation for dp/dx = 0 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 18 Simple velocity profile approximations: u U (2 y / y 2 / 2 ) u(0) = 0 u(δ) = U uy(δ)=0 no slip matching with outer flow Use velocity profile to get Cf() and () and then integrate momentum integral equation to get (Rex) δ* = δ/3 θ = 2δ/15 H= δ*/θ= 5/2 w 2U / 2 U / d d cf 2 2 (2 /15) 2 1/ 2 U dx dx 15 dx d U 30 dx 2 U / x 5.5 / Re1/2 x Re x Ux / ; * / x 1.83 / Re1/2 x / x 0.73 / Re1/2 x CD 1.46 / Re1/2 L 2C f ( L ) 10% error, cf. Blasius 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 19 Approximate solution Turbulent Boundary-Layer Ret = 5×105 3×106 for a flat plate boundary layer Recrit 100,000 c f d 2 dx as was done for the approximate laminar flat plate boundary-layer analysis, solve by expressing cf = cf () and = () and integrate, i.e. assume log-law valid across entire turbulent boundary-layer u 1 yu * ln B u* neglect laminar sub layer and velocity defect region at y = , u = U U 1 u * ln B u* 1/ 2 c Re f 2 or 2 cf 1/ 2 1/ 2 cf 2.44 ln Re 5 2 c f .02 Re 1 / 6 power-law fit cf () 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 20 Next, evaluate d d u u 1 dy dx dx 0 U U can use log-law or more simply a power law fit 1/ 7 u y Note: cannot be used to U obtain cf () since w 7 72 1 d 7 d w c f U 2 U 2 U 2 2 dx 72 dx d Re 1/ 6 9.72 dx 1/7 i.e., much faster or x 0.16 Re x growth rate than 6/7 almost linear x laminar boundary layer cf 0.027 Re1/7 x Cf 0.031 7 c f L Re1/7 6 L These formulas are valid for a fully turbulent flow over a smooth flat plate from the leading edge. Assuming the transition from laminar to turbulent occurs at Re larger than 105, those formulas in general give better results for sufficiently large Reynolds number ReL > 107. 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 21 Alternate forms by using the same velocity profile u/U = (y/)1/7 assumption but using an experimentally determined shear stress formula w = 0.0225U2(/U)1/4 are: 0.37 Re x 1/5 x shear stress: cf 0.058 Re1/5 x Cf 0.074 Re1/5 L 0.029 U 2 w Re1/5 x These formulas are valid only in the range of the experimental data, which covers ReL = 5 105 107 for smooth flat plates. Other empirical formulas for smooth flat plates are as follows: Total shear-stress coefficient Local shear-stress coefficient 𝐶𝑓 = (log 0.455 10 𝑅𝑒𝐿 ) 2.58 c f .98 log Re L .732 L c f 2 log Re x .65 2.3 For the experimental/empirical formulas, the boundary layer is usually “tripped” by some roughness or leading edge disturbance, to make the boundary layer turbulent from the leading edge. 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 22 Finally, composite formulas that take into account both the initial laminar boundary layer and subsequent turbulent boundary layer, i.e. in the transition region (5 105 < ReL < 8 107) where the laminar drag at the leading edge is an appreciable fraction of the total drag: 𝐶𝑓 = 0.031 1 7 𝑅𝑒𝐿 𝐶𝑓 = 0.074 1 𝑅𝑒𝐿5 1440 − 𝑅𝑒𝐿 − 1700 𝑅𝑒𝐿 or 𝐶𝑓 = 0.455 1700 − (log10 𝑅𝑒𝐿 )2.58 𝑅𝑒𝐿 with transitions at Ret = 5 105 for all cases. 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 23 Bluff Body Drag Drag of 2-D Bodies First consider a flat plate both parallel and normal to the flow C Dp Cf 1 1 2 S V A 2 1 1 2 S V A 2 p p n î 0 w t îdA = 1.33 Re1L/ 2 laminar flow = .074 Re1L/ 5 turbulent flow flow pattern vortex wake typical of bluff body flow where Cp based on experimental data 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 1 Chapter 9 24 p p n îdA 1 2 S V A 2 1 = C p dA AS = 2 using numerical integration of experimental data Cf = 0 C Dp For bluff body flow experimental data used for CD. 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 In general, Drag = f(V, L, , , c, t, , T, etc.) from dimensional analysis c/L CD t f Re, Ar, , , T, etc. 1 2 L L V A 2 Drag scale factor Chapter 9 25 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 26 a2 Potential Flow Solution: U r sin r 1 1 1 p V 2 p U 2 ur 2 2 r u 2r u 2 p p Cp 1 2 1 2 U U 2 C p r a 1 4 sin 2 u r surface pressure Flow Separation Flow separation: The fluid stream detaches itself from the surface of the body at sufficiently high velocities. Only appeared in viscous flow!! Flow separation forms the region called ‘separated region’ 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 27 Inside the separation region: low-pressure, existence of recirculating/backflows viscous and rotational effects are the most significant! Important physics related to flow separation: ’Stall’ for airplane (Recall the movie you saw at CFD-PreLab2!) Vortex shedding (Recall your work at CFD-Lab2, AOA=16°! What did you see in your velocity-vector plot at the trailing edge of the air foil?) 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 28 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 29 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 30 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 31 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 32 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 33 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 34 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 35 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 36 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 37 Terminal Velocity Terminal velocity is the maximum velocity attained by a falling body when the drag reaches a magnitude such that the sum of all external forces on the body is zero. Consider a sphere using Newton’ Second law: Z F F F F ma d b g when terminal velocity is attained F a 0: Fd Fb Fg or 1 V02CD Ap Sphere fluid V 2 For the sphere Ap 4 d2 and V Sphere 6 Sphere d3 The terminal velocity is: sphere fluid 4 3 d V0 CD fluid 12 Magnus effect: Lift generation by spinning Breaking the symmetry causes the lift! 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 38 Effect of the rate of rotation on the lift and drag coefficients of a smooth sphere: Lift acting on the airfoil Lift force: the component of the net force (viscous+pressure) that is perpendicular to the flow direction 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 39 Variation of the lift-to-drag ratio with angle of attack: The minimum flight velocity: Total weight W of the aircraft be equal to the lift W FL 1 2 C L ,max Vmin A Vmin 2 2W C L ,max A 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 40 Effect of Compressibility on Drag: CD = CD(Re, Ma) Ma U a speed of sound = rate at which infinitesimal disturbances are propagated from their source into undisturbed medium Ma < 1 Ma 1 Ma > 1 Ma >> 1 < 0.3 flow is incompressible, subsonic i.e., constant transonic (=1 sonic flow) supersonic hypersonic CD increases for Ma 1 due to shock waves and wave drag Macritical(sphere) .6 Macritical(slender bodies) 1 For U > a: upstream flow is not warned of approaching disturbance which results in the formation of shock waves across which flow properties and streamlines change discontinuously 57:020 Mechanics of Fluids and Transport Processes Professor Fred Stern Fall 2012 Chapter 9 41