04 CAT Unit Template - Auto Skills Australia

advertisement

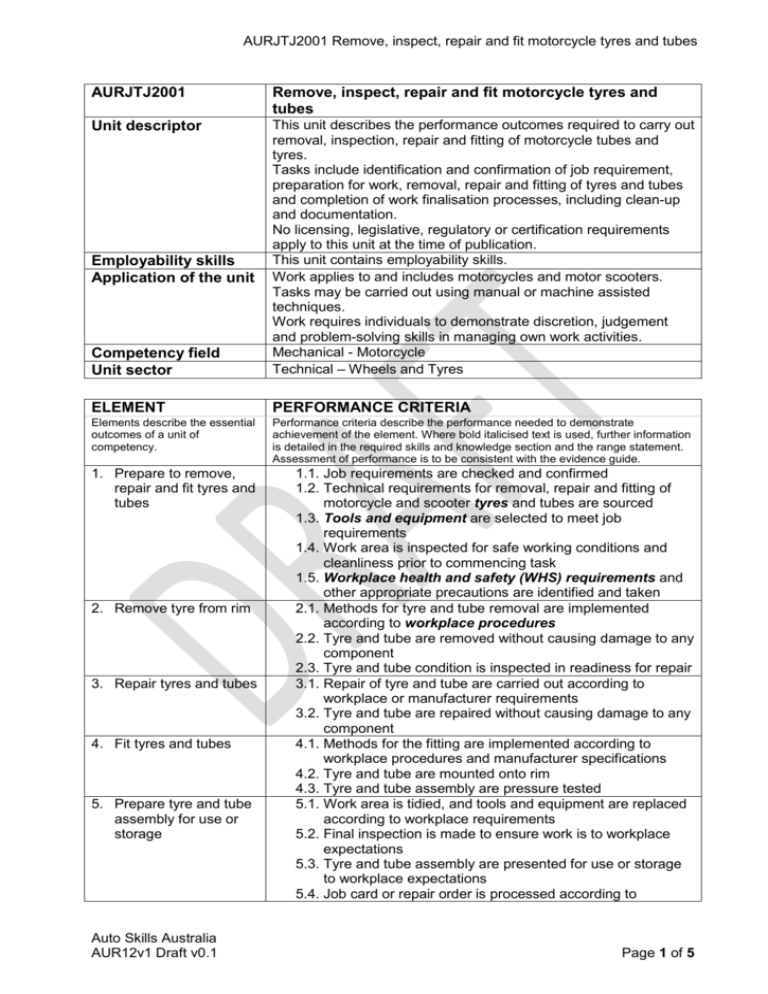

AURJTJ2001 Remove, inspect, repair and fit motorcycle tyres and tubes AURJTJ2001 Remove, inspect, repair and fit motorcycle tyres and tubes Unit descriptor Competency field Unit sector This unit describes the performance outcomes required to carry out removal, inspection, repair and fitting of motorcycle tubes and tyres. Tasks include identification and confirmation of job requirement, preparation for work, removal, repair and fitting of tyres and tubes and completion of work finalisation processes, including clean-up and documentation. No licensing, legislative, regulatory or certification requirements apply to this unit at the time of publication. This unit contains employability skills. Work applies to and includes motorcycles and motor scooters. Tasks may be carried out using manual or machine assisted techniques. Work requires individuals to demonstrate discretion, judgement and problem-solving skills in managing own work activities. Mechanical - Motorcycle Technical – Wheels and Tyres ELEMENT PERFORMANCE CRITERIA Elements describe the essential outcomes of a unit of competency. Performance criteria describe the performance needed to demonstrate achievement of the element. Where bold italicised text is used, further information is detailed in the required skills and knowledge section and the range statement. Assessment of performance is to be consistent with the evidence guide. 1. Prepare to remove, repair and fit tyres and tubes 1.1. Job requirements are checked and confirmed 1.2. Technical requirements for removal, repair and fitting of motorcycle and scooter tyres and tubes are sourced 1.3. Tools and equipment are selected to meet job requirements 1.4. Work area is inspected for safe working conditions and cleanliness prior to commencing task 1.5. Workplace health and safety (WHS) requirements and other appropriate precautions are identified and taken 2.1. Methods for tyre and tube removal are implemented according to workplace procedures 2.2. Tyre and tube are removed without causing damage to any component 2.3. Tyre and tube condition is inspected in readiness for repair 3.1. Repair of tyre and tube are carried out according to workplace or manufacturer requirements 3.2. Tyre and tube are repaired without causing damage to any component 4.1. Methods for the fitting are implemented according to workplace procedures and manufacturer specifications 4.2. Tyre and tube are mounted onto rim 4.3. Tyre and tube assembly are pressure tested 5.1. Work area is tidied, and tools and equipment are replaced according to workplace requirements 5.2. Final inspection is made to ensure work is to workplace expectations 5.3. Tyre and tube assembly are presented for use or storage to workplace expectations 5.4. Job card or repair order is processed according to Employability skills Application of the unit 2. Remove tyre from rim 3. Repair tyres and tubes 4. Fit tyres and tubes 5. Prepare tyre and tube assembly for use or storage Auto Skills Australia AUR12v1 Draft v0.1 Page 1 of 5 AURJTJ2001 Remove, inspect, repair and fit motorcycle tyres and tubes ELEMENT PERFORMANCE CRITERIA workplace requirements REQUIRED SKILLS AND KNOWLEDGE This section describes the skills and knowledge required for this unit. Required skills technical skills to: ◦ apply technical information relating to motorcycle and scooter tyre and tube repair procedures ◦ select tools and equipment appropriate to the task ◦ safely use tools and equipment to perform tyre and tube repairs to motorcycles communication skills to: ◦ confirm work requirements and specifications ◦ report work outcomes and problems ◦ oral communication skills sufficient to convey information and concepts to customers literacy skills: ◦ reading skills to the level required to understand information relating to work orders, including common industry terminology and safety procedures ◦ writing skills to prepare reports and interpret technical information and specifications numeracy skills to: ◦ correctly interpret metric and non-metric systems of measurement as they apply to tyres and tubes planning and organising skills to: ◦ identify risk factors to minimise risk to self and others ◦ contribute to activities which implement and follow standard workplace procedures problem-solving skills to: ◦ identify technical and procedural problems ◦ refer problems outside area of responsibility to appropriate person self-management skills to: ◦ locate and identify appropriate tyre repair tools and equipment ◦ recognise limitations and seek timely advice ◦ follow basic workplace documentation, such as job requirement or procedures technology skills to: ◦ use workplace technology relating to the removal, repair and fitting of tubes and tyres ◦ use computerised technology for the reporting/documenting of results Required knowledge motorcycle and tyre manufacturer specifications and instructions WHS requirements, including personal safety relevant to working with motorcycles, tyres and tubes workplace processes relating to motorcycle tyres and tubes dangers of working with tyre changing equipment general knowledge of types of rim and tyre construction, terms and codes tyre and tube removal, repair and fitting procedures workplace documentation procedures Auto Skills Australia AUR12v1 Draft v0.1 Page 2 of 5 AURJTJ2001 Remove, inspect, repair and fit motorcycle tyres and tubes RANGE STATEMENT The range statement relates to the unit of competency as a whole. It allows for different work environments and situations that may affect performance. Bold italicised wording, if used in the performance criteria, is detailed below. Essential operating conditions that may be present with training and assessment (depending on the work situation, needs of the candidate, accessibility of the item, and local industry and regional contexts) may also be included. Tyres may include: Tools and equipment may include: OHS requirements may include: Workplace procedures may include: Auto Skills Australia AUR12v1 Draft v0.1 tube type tubeless radial belted bias directional hand tools tyre levers power tools specialised equipment such as: ◦ buffs ◦ spreaders ◦ tyre removal equipment ◦ immersion tanks ◦ other various tyre and tube repair material personal protective equipment and clothing safety equipment safe work procedures relating to performing tyre and tube repair hazard and risk control manual handling, including shifting, lifting and carrying emergency procedures verbal or written and graphical instructions signage, work schedules/plans/specifications, work bulletins safe work procedures related to the removal, repair and fitting of motorcycle and scooter tubes and tyres regulatory/legislative requirements pertaining to the automotive industry, including Australian Design Rules manufacturer specifications and instructions organisation work specifications and requirements Australian Standards Page 3 of 5 AURJTJ2001 Remove, inspect, repair and fit motorcycle tyres and tubes EVIDENCE GUIDE The evidence guide provides advice on assessment and must be read in conjunction with the performance criteria, required skills and knowledge, range statement and the Assessment Guidelines for the Training Package. Overview of assessment Critical aspects for assessment and evidence required to demonstrate competency in this unit Context of, and specific resources for assessment Method of assessment Auto Skills Australia AUR12v1 Draft v0.1 The evidence required to demonstrate competency in this unit must be relevant to workplace operations and satisfy all of the requirements of the performance criteria and required skills and knowledge. A person who demonstrates competency in this unit must be able to: observe workplace safety procedures and requirements select methods and techniques appropriate to the circumstances carry out the removal, inspection and fitting of motorcycle tyres and tubes according to workplace and manufacturer requirements complete the repair of tyres and tubes according to requirements present wheel assembly to workplace expectations in compliance with workplace requirements completion of reporting / work finalisation documentation according to workplace requirements Competency is to be assessed in the workplace or a simulated workplace environment that accurately reflects performance in a real workplace setting. Assessment is to occur: using standard workplace practices and procedures following safety requirements applying environmental constraints. Assessment is to comply with relevant: regulatory requirements Australian standards industry codes of practice. The following resources should be made available: workplace location or simulated workplace motorcycle wheels, tyres and tubes representative of a range of different types material relevant to the removal, repair and fitting of tyres and tubes for motorcycles equipment, hand and power tools appropriate to the removal, repair and fitting of tyres and tubes specifications and work instructions Assessment must satisfy the endorsed Assessment Guidelines of this Training Package. Assessment methods must confirm consistency and accuracy of performance (over time and in a range of workplace relevant contexts) together with the application of required skills and knowledge. Assessment methods must be by direct observation of tasks and include questioning on required skills and knowledge to ensure correct interpretation and application. Competence in this unit may be assessed in conjunction with Page 4 of 5 AURJTJ2001 Remove, inspect, repair and fit motorcycle tyres and tubes EVIDENCE GUIDE other units which together form part of an holistic work role. Where applicable, reasonable adjustment must be made to work environments and training situations to accommodate the needs of diverse clients. Assessment processes and techniques must be culturally sensitive and appropriate to the language, literacy and numeracy capacity of the candidate and the work being performed. Auto Skills Australia AUR12v1 Draft v0.1 Page 5 of 5