guidance on coshh assessments - mmsc012

advertisement

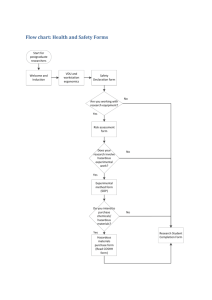

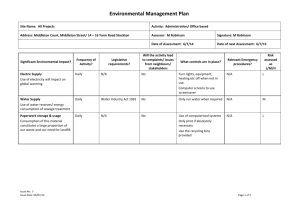

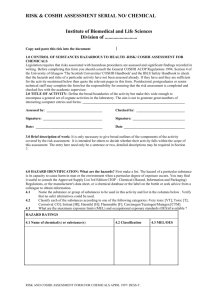

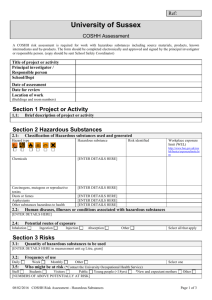

SOM008 GUIDANCE ON COSHH ASSESSMENTS The Control of Substances Hazardous to Health Regulations 2002 (amended 2004) Introduction Before anyone can carry out any procedure involving hazardous substances it is first compulsory that they carry out a Risk Assessment and a COSHH risk assessment. It is the responsibility of the individual Supervisors to make sure this is done. Any student/staff member who carries out a hazardous procedure, without first informing their supervisor and completing a Risk and COSHH assessment, and if this results in an injury to themselves or a third party, they may be liable. The Control of Substances Hazardous to Health Regulations (COSHH) requires that: 1. An assessment is made of the risks to health posed by activities which could expose persons to any hazardous substance at work. 2. Exposure to substances hazardous to health is prevented or, where this is not reasonably practical, exposure is adequately controlled. 3. All control measures are maintained in efficient working order. 4. The exposure is monitored where it is necessary to ensure the maintenance of adequate control and health surveillance is provided where appropriate. 5. Researchers / Students are informed, instructed and trained about the risks to health and the precautions to be taken with regard to hazardous substances. THE ASSESSMENT A safety assessment MUST be completed before any work involving a hazardous substance is carried out. The safety assessment comprises of a Risk assessment that identifies the practical hazards in a procedure or task (e.g. heat and electricity hazard of a hot plate, working with glassware) and an additional COSHH assessment is required (e.g. chemical burns from the hot chemical), which identifies the chemical hazards in a procedure or task. The COSHH assessment focuses on the risks to health which may arise from the procedure or task from the hazardous substances being used or created that could enter the body by inhalation, ingestion, or through the skin, or may cause damage by contact with the body (e.g. eyes, skin) or affect the environment. A 'hazardous substance' is anything classified as dangerous to health under the current CHIP’s (Chemical Hazards Information and Packaging) regulations, or substances which have a Maximum Exposure Limit (MEL) or are subject to an Occupational Exposure Standard (OES) (as given in the Health and Safety Guidance Note EH40) OR dust of any kind when present in quantity, or micro-organisms, or any substance that creates a comparable hazard to the above. In practice this means anything that is supplied with a warning label of any kind, or anything that is listed as hazardous. Following the assessments of the hazards and risks, the precautions/control measures needed for control of the hazards are drawn up. Separate assessments are required for each distinct procedure, but a single assessment may cover the activities of many individuals. i.e. a single Risk Assessment may describe the procedure and its hazards etc, but this task may be done with many different chemicals. So there could be one Risk Assessment but many associated COSHH Assessments, as the procedure is the same but the chemicals change and also the associated hazards. COMPLETING SAFETY ASSESSMENTS involving Chemicals 1) Risk Assessment – Complete a Risk assessment of the task / procedure (SOM002) identifying a physical and chemical hazards and a need for a COSHH risk assessment. 2) COSHH Risk Assessment (SOM003) – complete the COSHH Risk Assessment. Fill in ALL sections The COSHH Risk Assessment must make reference to the associated Risk assessment Include all those at risk when indicating persons involved Keep the “Title” brief (short but sufficient) Keep the “Description of procedure” terse and brief as it only used to help to understand the procedure ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596 1 SOM008 Use CAS numbers as well as chemical names – this helps to identify chemical, try to avoid the use of abbreviations other than chemical formulae. Identify the likely volumes / amounts and concentrations to be used. Also indicate the temperature if not at room temperature or any other environmental factor that may apply, e.g. vacuum. Chemical safety information can be found from ‘Safety Data sheets’ (was MSDS). There is, in the UK, currently two systems for safety hazards and safety information the old – MSDS (Materials Science Data Sheets) and the new – SDS (Safety data Sheets). SDS will gradually replace MSDS. MSDS uses Risk Phrases and Safety Phrases, SDS uses Hazard Statements (physical health and environment) and Precautionary Statements (general, prevention, response storage and disposal). See SOM010 and SOM032 for guidance. Identify hazards associated with each chemical Records must be kept by all ‘users’ of certain hazardous chemicals, namely chemicals that the authorities have deemed Carcinogenic, Mutagenic, Reproductive Toxins, Sensitisers and Poisons. A ‘CMR form’, SOM029 must be completed by all users of these chemicals; they must also read SOM115 which are guidance notes when using these chemicals. Identify hazards associated with possible reaction products, if unknown, try make a judgement based on similar substances or procedures Identify sources of information – try to keep to UK sources Identify control measures to be adopted, include exposure levels if applicable Clearly identify what Personal Protective Equipment is required and ensure it is suitable and sufficient for the activity Identify disposal procedures and if cost involved include a charge code. Identify emergency procedures for all scenarios, large spill, small spill, fire, harm? Indicate start, review and finish date, i.e. duration of experimental work Have the Risk Assessment and associated COSHH assessment authorised by supervisor The Supervisor must indicate if task is allowed ‘out-of-hours’ Send approved originals of both Risk and associated COSHH assessments to Safety Advisor for a reference number and including into the database and copies returned. Copies of approved safety assessments to be kept in the red safety folder in the laboratory where the work is to be done and put on visual display near to the more hazardous tasks. 3) Re-Assessments Risk Assessment and associated safety assessments must be re-assessed if: Any change in legislation or guidelines – e.g. change in the regulations Any change to the assessed task – e.g. change in concentration Any change in “who might be harmed” – e.g. change in class of user Any change in location of task – e.g. move task to smaller room Any modifications to task – e.g. change from gas to electric heating Any other factor that may affect the risks of the task – e.g. Pregnancy One year since last assessment 4) Review A COSHH assessment review is where a supervisor or competent person re-authorises a COSHH assessment. A COSHH assessment must be reviewed when: The annual renewal date is reached and the COSHH assessment is still suitable and sufficient, i.e. it identifies all the potential hazards, harm and control measures to prevent harm. A small change to the existing COSHH assessment is required, i.e. where there is no increased risk. When a COSHH assessment is reviewed a copy of the new risk assessment must be sent to the Safety Advisor to record the review and any changes. ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596 2 SOM008 5) Difficulties Contact your Supervisor or Safety Advisor for help and advice. ivan.easdon@manchester.ac.uk (School Senior Safety Advisor) room C15, Materials Science Building, Ext. 63596 3