ERTK Plan - University of Minnesota Duluth

advertisement

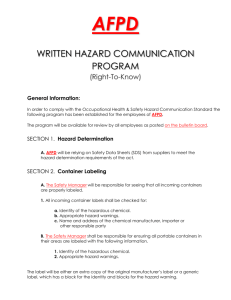

University of Minnesota | Duluth Employee Right-to-Know Plan [YOUR DEPARTMENT NAME] Prepared by: [Coordinator’s Name] Date: [___________] Employee Right-To-Know Plan UNIVERSITY OF MINNESOTA | DULUTH [Insert Department Name] FORWARD In 1983, the Minnesota Legislature passed the Employee Right-to-Know (ERTK) Act, requiring all employers to develop written training programs for their employees regarding the hazardous substances, harmful physical agents and infectious agents they are routinely exposed to in the workplace. To guide employers with creating these training programs, Minnesota OSHA underwent public rulemaking to add Chapter 5206 to the Minnesota Rules, which spells out the required contents of the program, including training, labeling and additional information. In September 10, 2012, MNOHSA adopted the new GHS (Globally Harmonized System for the classification and labeling of chemicals), a worldwide effort to standard hazardous communications. The new GHS requires using specific criteria for container labeling including pictograms/symbols, and a harmonized format for safety data sheets using a standardized 16‐element format. In brief, Per MN Rule 5206, the written program must include: A plan for providing training to employees prior to initial or change in work assignment or conditions, and annual refresher training, including an outline of training content; Methods for making ERTK information, such as safety data sheets (SDSs), readily accessible to employees in their work areas; A description of how labels, placards and signs will be used to identify hazardous materials or work areas where harmful physical agents are generated at levels approaching regulatory limits; A list of hazardous substances and agents present in the workplace; and The methods used to inform employees of the hazards of infrequent tasks The following employee right-to-know program is based on a template from the MNOSHA plan tailored to fit University departments’ needs. Please Call EHSO at 726-7273 or 726-6917 if you have questions about this program or on how to implement it. Revised on 1/10/14 Page: 2 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH STATEMENT OF POLICY The [Insert Department Name here] is committed to maintaining a safe and healthy work environment in all its facilities, and recognizes that a plan to educate/inform employees about the dangers of exposure to hazardous Chemicals, Physical and infectious agents is important. This written plan is established to ensure that the [Insert Department Name here] is complying with the Minnesota OSHA Employee Right-to-Know (ERTK) standard by Providing all employees training about the hazardous materials, harmful physical agents and infectious agents to which they are exposed on the job. Compiling a list of the hazardous chemicals used by employees in all department operations Collecting and compiling Safety Data Sheets (SDSs) used in our facilities Compiling a list of harmful agents employees are exposed to and their corresponding reference materials, Ensuring that containers are labeled according to new GHS criteria and signs are present in the hazardous areas. SCOPE AND APPLICATION This program applies to all work operations where employees may be exposed to hazardous substances, harmful physical agents or infectious agents under normal working conditions or during an emergency situation. This program does not apply to laboratory employees With this program [Insert Department Name here] employees will be informed of the content of the Minnesota OSHA Employee Right-to-Know standard, the hazardous properties of the chemicals they work with, the safe handling procedures and proper measures to take to protect themselves from these chemicals. They will also be informed of the hazards associated with non-routine tasks. The department and the University will make every effort to inform employees of any hazards created by other employers and their employees working in area where our employees are. RESPONSIBILITIES [Name or job title] is the program coordinator and has overall responsibility for the program. [Name or job title] will review and update the program, as necessary including the following: Compile the names of all department employees who because of the nature of their jobs are included under the ERTK Compile a list of all hazardous materials used and their corresponding Safety Data Sheets (SDS) Compile a list of all harmful physical and infectious agents present in the workplace and their corresponding SDS or reference materials Ensure all chemical containers used in the workplace are labeled according the new GHS labeling requirements and all area where there is a harmful physical agent are labeled. Ensure all employees are aware of this written plan and arrange for training. Copies of this written program may be obtained from [Name or job title]. Revised on 1/10/14 Page: 3 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH TRAINING Everyone who works with or is potentially exposed to hazardous chemicals, harmful physical agents or infectious agents will receive initial training about the Employee Right-to-Know standard (ERTK) and the safe use of those chemicals or agents prior to work assignment. A Training program has been prepared for this purpose and is outlined below. Also Whenever a new hazard is introduced, additional training will be provided, or at least the employee will be given the opportunity to review the SDS and sign a form (see appendix 6) acknowledging receipt of the information. Training updates will be performed at least annually and may be brief summaries of information included in previous training sessions. The program coordinator is responsible for ensuring this training is provided. TRAINING CONTENT The employee right-to-know training will include: A summary of the standard and this written program; The chemical and physical properties of hazardous materials and methods that can be used to detect the presence or release of chemicals. The physical hazards of chemicals (e.g., potential for fire, explosion, etc.); The name of the substance or agent and the level or concentration at which exposure to the hazard is permitted (Permissible Exposure Limits1), or if no levels have been adopted, according to guidelines established by competent professional groups (i.e. ACGIH TLVs2, or NIOSH RELs3); The health hazards, including signs and symptoms, associated with exposure to chemicals, harmful physical agents and infectious agents, and any medical condition known to be aggravated by exposure to these hazards; The procedures to protect against those hazards (e.g., use and maintenance of personal protective equipment; work practices or methods for proper use and handling of chemicals; and procedures for emergency response); The work procedures to follow to assure protection when cleaning up incidental spills and leaks of hazardous chemicals; The location in the facility where SDSs, physical agent data sheets (PADSs) and infectious agents information can be found; Information on how to read, interpret, and use the new SDS, MSD, and PADSs; Instruction about how to read and interpret the information on labels including explanation of the GHS label components i.e. product identifier, the new hazard pictograms, signal words, the hazard statement and the precautionary statement. Any additional information about how employees may obtain additional hazard information. Revised on 1/10/14 Page: 4 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH RECORD KEEPING Records of training will be maintained for three years in the department or area Safety Compliance Documentation Manual and will include: The dates of training; The name, title and qualifications of the person who conducted the training; The names and ID# of the employees who completed the training; and their signature A brief summary or outline of the information that was included in the training session. A copy of the training record form is included in appendix-1 LIST OF HAZARDOUS CHEMICALS [Name or job title] has compiled the following list of all hazardous substances, names of exposed employees, and corresponding work area in the facility, and will update the list as necessary. The list of chemicals identifies all of the chemicals used per work areas. The list also identifies the corresponding SDS for each chemical. See appendix-1 for a copy of the list. LIST OF HARMFUL PHYSICAL AGENTS (if applicable to the facility) [Name or job title] has compiled a list of all the harmful physical agents that are present in the workplace in amounts approaching regulatory limits i.e. < 85 dBA for noise, through equipment use, product handling, etc. Heat, noise, ionizing radiation and nonionizing radiation sources have been identified for each work area. And a risk assessment has been conducted to quantify the hazard and ensure compliance with other pertinent state or federal standards. Each list also identifies the corresponding physical agent data sheet for each source. The list of all physical agents can be found in appendix-3. For Noise levels (NL) > 85dBA compliance with the UMD Hearing Conservation Program is required. The list of physical agents may include: Noise Ionizing Radiation and Non-Ionizing Radiation Heat Cold UV radiation Laser Vibration Revised on 1/10/14 Page: 5 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH LIST OF INFECTIOUS AGENTS (if applicable to the facility, or when workers are assigned first aid responsibilities as part of their job duties) [Name or job title] has created a list of infectious agents that workers are routinely exposed to in the course of assigned work. This includes designated first aid providers who have potential exposure to bloodborne pathogens. For further information, see the University Exposure Control Plan for the facility that meets the requirements set forth in 29 CFR 1910.1030 and that covers all infectious agents, including bloodborne pathogens. If applicable the list can be found in appendix-4 Infectious Agents Data Sheets (IADS) may be obtained from the UMD EHS office. SAFETY DATA SHEETS (SDS) Safety Data Sheets (SDS) provide specific information about the chemicals and are an essential component of the UMD Occupational Safety and Health Program and this ERTK plan. The program coordinator is responsible for acquiring and updating the SDS list will maintain a binder in [location Name] with an SDS about every substance on the list of hazardous chemicals identified in the facility are listed in appendix-2. The program coordinator will contact the chemical manufacturer or vendor if additional research is necessary or if an SDS has not been supplied with an initial shipment. All facility supervisors will assist the program coordinator in collecting or forwarding the SDS of all materials they purchased /brought into the facility. HARMFUL PHYSICAL AGENTS INFORMATION (if applicable to the facility) The program coordinator is responsible for acquiring a Physical Agent Data Sheet (PADS) or comparable written information about the identified harmful physical agents employees may be exposed to in the course of assigned work From the Office of Environmental Health and Safety. The PADS or other written information will be maintained in a binder in [location]. INFECTIOUS AGENT INFORMATION (if applicable to the facility) Information about infectious disease hazards in the workplace can be found in the University Exposure Control Plan. A printed copy is located in [location]. LABELS AND OTHER FORMS OF WARNING The program coordinator will ensure all hazardous chemical containers in the facility are properly labeled and updated as necessary. Manufacturer’s container labels should be left on the containers if possible and must list, at a minimum, the chemical’s identity or product identifier, the new hazard pictograms, signal words, the hazard statement and the precautionary statement, as well as the name and address of the manufacturer, importer or other responsible party. Revised on 1/10/14 Page: 6 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH If chemicals are transferred from a manufacturer’s container into another container, the new container must have a label that identifies the chemical identity and any appropriate hazard warning. It must include at least the following for element of the new GHS labeling system, i.e. the Product identifier, the required pictogram(s), and the hazard statement. Immediate-use containers, which are containers of hazardous substances remaining under the control of one employee and that are emptied during the same work shift, need not be labeled. See the UMD Step by Step to Container Labeling The program coordinator will ensure equipment or work areas that specifically generate harmful physical agents at a level that may be expected to approximate or exceed the permissible exposure limit or applicable action level are posted with the name of the physical agent and the appropriate hazard warning. The exposure control plan for the facility addresses the labeling procedures for receptacles containing potentially infectious material. NON-ROUTINE TASKS When employees are required to perform hazardous non-routine tasks, the UMD Environmental Health and Safety Staff will conduct a special training session to inform the employees about the hazardous chemicals they might be exposed to and the proper precautions to take to reduce or avoid exposure. SDSs will be made available about the hazardous chemicals used. The program coordinator is responsible for ensuring this training is provided. MULTI-EMPLOYER WORKPLACE A work area or building becomes a multi employer workplace when contractors such as service representatives or subcontractors or FM employees are performing repair, maintenance, or construction at your building, or work area, in this case the program coordinator along with the appropriate EHSO staff will: 1. Obtain SDSs copies of the material/substance used from Facilities Management and share it with the department or affected staff, as well as inform the staff of any precautionary measure they need to take to avoid exposure. 2. Provide the visiting employers with SDS for any relevant hazardous substances present at the worksite that the visiting employees may be exposed to while working at your facility; 3. Inform the other employer of any precautionary measures that need to be taken to protect the employees during both normal working conditions and in foreseeable emergencies; and 4. Inform the other employer about the labeling system used in the facility. The program coordinator will document in writing that the above information was conveyed to the other employer. Revised on 1/10/14 Page: 7 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH FREQUENCY OF TRAINING The program coordinator jointly with department safety committee and the appropriate staff from UMD EHS Office will review the employee training program on a regular basis and will advise management regarding initial or annual refresher training needs. Retraining is also required whenever a new hazard is introduced into the workplace. As part of the assessment of the training program, the program coordinator will obtain input from employees regarding the training they have received and their suggestions for improving it. This review will be performed annually; necessary revisions will be made to ensure training is current and applicable. Revised on 1/10/14 Page: 8 Employee Right-To-Know Plan UNIVERSITY OF MINNESOTA | DULUTH [Insert Department Name] Employee Right-To-Know Annual Program Review Documentation The following activities have been completed: Is Written Plan up-to-date? Has hazardous substance inventory been updated? Has physical agents inventory been updated? Is training up to date? Are all SDS up to date? Is labeling up to date and all chemicals are properly labeled? All portable containers are properly labeled _____Yes, _____Yes, _____Yes, _____Yes, _____Yes, _____Yes, _____Yes, _____No _____No _____No _____No _____No _____No _____No Training Number of Training Courses Presented: Types of Training Provided Number of Employees Trained: New employee RTK training: Work-area-specific training: New-substance training: Other training: Total courses & employees Hazardous Substances & Physical Agents Hazardous Substances in Use Safety Data Sheets on File: Previous Total New This Year Revised Total If any of the above activities are not complete, explain: Completed By: ______________________________________ Date: ________________________ Revised on 1/10/14 Page: 9 Employee Right-To-Know Plan UNIVERSITY OF MINNESOTA | DULUTH [Insert Department Name] PLAN APPROVALS ________________________________________ Program coordinator ________________________ Date ________________________________________ Reviewed by ________________________ Date ________________________________________ Upper Management Approval (Name & title) ________________________ Date Revised on 1/10/14 Page: 10 Employee Right-To-Know Plan UNIVERSITY OF MINNESOTA | DULUTH [Insert Department Name] APPENDIX-1: TRAINING DOCUMENTATION FORM University of Minnesota | Duluth Hazardous Substance, Employee Right-to-Know Standard (MN-OSHA Rules Chapter 5206) TRAINING RECORD Date: Location: Department Name Length of Training Name of Trainer Qualifications of Trainer Job Title of Trainer Occupational Health Safety and Environmental Compliance Professional Covered Subjects A summary of the standard and the ERTK written program; The chemical and physical properties of hazardous materials and methods that can be used to detect the presence or release of chemicals. The physical hazards of chemicals (e.g., potential for fire, explosion, etc.); The level or concentration of the substance at which exposure to the hazard is permitted (Permissible Exposure Limits), or if no levels have been adopted, according to guidelines established by competent professional groups (i.e. ACGIH TLVs, or NIOSH RELs); The health hazards, including signs and symptoms, associated with exposure to chemicals, harmful physical agents and infectious agents, and any medical condition known to be aggravated by exposure to these hazards; The procedures to protect against those hazards (e.g., use and maintenance of personal protective equipment; work practices or methods for proper use and handling of chemicals; and procedures for emergency response); The work procedures to follow to assure protection when cleaning up incidental spills and leaks of hazardous chemicals; The location in the facility where SDSs, physical agent data sheets (PADSs) and infectious agents information can be found; Information on how to read, interpret, and use the new SDS, MSD, and PADSs; Instruction about how to read and interpret the information on labels including explanation of the GHS label components i.e. product identifier, the new hazard pictograms, signal words, the hazard statement and the precautionary statement. CERTIFICATION Name Revised on 1/10/14 Employee ID # Signature Page: 11 Employee Right-To-Know Plan UNIVERSITY OF MINNESOTA | DULUTH [Insert Department Name] APPENDIX-2: LIST OF HAZARDOUS CHEMICALS Work Area/Job Task Employee Name Chemicals used SDS Available SDS up-to-date The List of hazardous chemicals shall also include all hazardous substances generated during work operations. And exposure to these substances shall also be documented. Some examples include: Welding fumes Wood and other dusts Carbon monoxide generated by propane or gas powered vehicles Nitrogen Dioxide, or Sulfur Dioxide from diesel powered vehicles Revised on 1/10/14 Page: 12 Employee Right-To-Know Plan UNIVERSITY OF MINNESOTA | DULUTH [Insert Department Name] APPENDIX-3: LIST OF PHYSICAL AGENTS Work Area/Job Task Employee Name Physical Agent Equipment Exposure Level Noise Ionizing Radiation Microwave Radiation Heat Cold UV Radiation Vibration Laser Revised on 1/10/14 Page: 13 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH APPENDIX-4: LIST OF INFECTIOUS AGENTS Work Area/Job Task Revised on 1/10/14 Employee Name Infectious agent Required Training Required Immunization Page: 14 Employee Right-To-Know Plan UNIVERSITY OF MINNESOTA | DULUTH [Insert Department Name] APPENDIX-5: SECONDARY CONTAINER LABELING Secondary container label using Acetone As an example of a container used in a Lab or a shop, Laboratories may omit the use of pictograms on secondary containers. 1. Identifier ---> Acetone 2. Pictogram ---> 3. Signal Word ---> DANGER! 4. Hazard Statement ---> Flammable Liquid Note: Laboratories may choose not to use the pictogram Revised on 1/10/14 Page: 15 Employee Right-To-Know Plan UNIVERSITY OF MINNESOTA | DULUTH [Insert Department Name] APPENDIX-6: NEW CHEMICAL SUBSTANCE REVIEW University of Minnesota | Duluth SAFETY DATA SHEET (SDS) FOR A NEW CHEMICAL/SUBSTANCE SIGNATURE FORM Name Chemical/Substance: Vendor/manufacturer’s Name: Lab Location: Date the Chemical Arrived: Date of providing (SDS) to employee(s): This chemical may have health effects or other hazardous properties not covered during your initial ERTK/ Lab Safety Training Session. Because of your use of this chemical, you are asked to read the attached Safety Data Sheet (SDS) to understand the hazards and the new health effects associated with the use of ____________________________________ Any question or concerns about your safety handling the chemical, the chemical health or physical hazards hazard, may be addressed to your supervisor or Environmental Health and Safety Office Upon reviewing the Safety Data Sheet (SDS), employees must sign and date this form. Name Revised on 1/10/14 Employee ID # Signature Page: 16 Employee Right-To-Know Plan [Insert Department Name] APPENDIX-7: UNIVERSITY OF MINNESOTA | DULUTH EXAMPLES OF PHYSICAL HAZARDS WARNING SIGNS 1. Noise Levels (NL > 80dBA) Revised on 1/10/14 Page: 17 Employee Right-To-Know Plan [Insert Department Name] Revised on 1/10/14 UNIVERSITY OF MINNESOTA | DULUTH Page: 18 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH 2. Heat Warning Sign Revised on 1/10/14 Page: 19 Employee Right-To-Know Plan [Insert Department Name] Revised on 1/10/14 UNIVERSITY OF MINNESOTA | DULUTH Page: 20 Employee Right-To-Know Plan [Insert Department Name] Revised on 1/10/14 UNIVERSITY OF MINNESOTA | DULUTH Page: 21 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH 3. Cold Temperatures Revised on 1/10/14 Page: 22 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH 4. Microwave Radiation Revised on 1/10/14 Page: 23 Employee Right-To-Know Plan [Insert Department Name] Revised on 1/10/14 UNIVERSITY OF MINNESOTA | DULUTH Page: 24 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH 5. Laser Radiation Revised on 1/10/14 Page: 25 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH 6. UV Light Radiation Revised on 1/10/14 Page: 26 Employee Right-To-Know Plan [Insert Department Name] UNIVERSITY OF MINNESOTA | DULUTH 7. Hand and Arm Vibration Hazard Revised on 1/10/14 Page: 27 Employee Right-To-Know Plan [Insert Department Name] Revised on 1/10/14 UNIVERSITY OF MINNESOTA | DULUTH Page: 28