GHS_written_training_program

advertisement

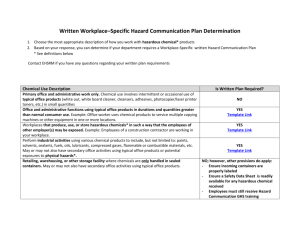

AFPD WRITTEN HAZARD COMMUNICATION PROGRAM General Information: In order to comply with the Occupational Health & Safety Hazard Communication Standard the following program has been established for the employees of AFPD. The program will be available for review by all employees as posted on the bulletin board. SECTION 1. Hazard Determination A. AFPD will be relying on Safety Data Sheets (SDS) from suppliers to meet the hazard determination requirements of the act. SECTION 2. Container Labeling A. The Safety Manager will be responsible for seeing that all incoming containers are properly labeled. 1. All incoming container labels shall be checked for: a. Identity of the hazardous chemical. b. Appropriate hazard warnings. c. Name and address of the chemical manufacturer, importer or other responsible party B. The Safety Manager shall be responsible for ensuring all portable containers in their areas are labeled with the following information. 1. Identity of the hazardous chemical. 2. Appropriate hazard warnings. The label will be either an extra copy of the original manufacturer’s label or a generic label, which has a block for the identity and blocks for the hazard warning. Piping systems shall be identified at access points and every 10 feet where piping is 10 feet or closer to employee contact. The method of identification will be Labels SECTION 3. Safety Data Sheets (SDS) A. The Safety Manager will be responsible for compiling the hazardous chemical list. SDS’s are available by accessing the 3-ring binder labeled SDS’s located under the counter near the cash register. B. SDS’s received from suppliers will be checked for completeness by the Safety Manager C. Notification of new or revised SDS’s will be accomplished by means of posting within 5 days of receipt. The posting will indicate: 1. New or revised title 2. Date of receipt 3. Posting date 4. Location of the new or revised SDS SECTION 4. Employee Information and Training A. The Safety Manager shall coordinate and maintain records of all Right to Know training. B. All employees will receive training regarding Hazardous Materials used in their department. All new employees will be likewise trained before starting work. C. The training will have information regarding: 1. An overview of the requirements contained in the Hazard Communication 2. Chemicals present in their workplace operations. 3. Location and availability of our written program. 4. Physical and health effects of the hazardous chemicals. 5. Methods of observation techniques used to determine the presents or release of hazardous chemicals in the work area. 6. How to lessen or prevent exposure to these hazardous chemicals through the usage of control/work practices and personal protective equipment. 7. Steps the company has taken to lessen or prevent exposure to these chemicals. 8. Emergency procedures to follow if they are exposed to these chemicals. 9. How to read labels and review SDS’s to obtain appropriate hazard information. After attending training class, each employee will sign a form to verify that he/she has attended the training, and understands the policies on Hazard Communication. Prior to a new hazardous chemical being introduced, each employee will be given information as outlined above. The Safety Manager is responsible to ensure that the SDS’s on the new chemical(s) list are available. SECTION 5. Hazardous Nonroutine Tasks A. Periodically, employees are required to perform hazardous nonroutine tasks. Prior to starting work on such projects, each affected employee will be given information by their manager about hazardous chemicals to which they may be exposed to during such activity. This information will include: 1. Specific chemical hazards. 2. Protective/safety measures the employee can take. 3. Measures the company has taken to lessen the hazards including ventilation, respirators, presence of another employee and emergency procedures. Periodic safety meetings will be held to ensure all employees retain prior training and information provided by management. Notices will be posted on the employee bulletin boards that provide the location of the written hazard communication program and SDS’s. B. It is policy that no employee will begin work in a confined space or on any nonroutine task without first receiving safety training from the Safety Manager. SECTION 6. Informing Contractors A. It is the responsibility of management at AFPD to provide contractors and their employees with the following information: 1. Hazardous chemicals, which they may be exposed to while the job, site. 2. Measures the employee may take to lessen their risk. 3. SDS’s for all hazardous chemicals are on file in the Service 4. Procedures to follow if they are exposed. B. The Safety Manager will coordinate with the contractor supervisor to ensure all employees are given appropriate information prior to entering the work site. SECTION 7. List of Hazardous Chemicals A list of all HAZARDOUS CHEMICALS used, can be found in the Right-To-Know SDS Binder located under the counter near the Cash Register. AN EMPLOYEE WHO NEEDS ASSISTANCE IN ACCESSING An SDS CAN CONTACT THE SAFETY MANAGER.