revised Online Supplemental Material

advertisement

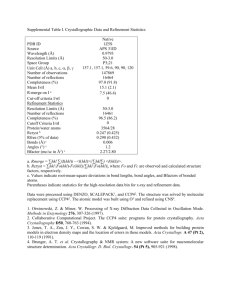

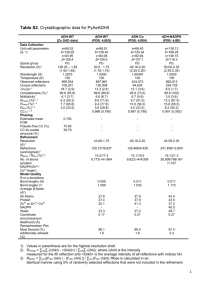

Strong piezoelectric anisotropy d15/d33 in <111> textured Pb(Mg1/3Nb2/3)O3Pb(Zr,Ti)O3 ceramics Yongke Yan a) and Shashank Priya b) Center for Energy Harvesting Materials and Systems, Virginia Tech, Blacksburg, Virginia 24061, USA Online Supplemental Materials 1. Material synthesis The composition 0.4Pb(Mg1/3Nb2/3)O3-0.25PbZrO3-0.35PbTiO3 (PMN-PZT) was chosen as the matrix and 2 vol% of plate-like <111> BaTiO3 (BT) template were used for texturing though the templated grain growth method. (1) Synthesis PMN-PZT matrix powder: PMN-PZT matrix powder was synthesized by conventional solid state reaction. Mixture of 2PbCO3∙Pb(OH)2 (99.9%, Sigma Aldrich, St. Louis, MO), MgNb2O6(99.9%, Alfa Aesar, Ward Hill, MA), Nb2O5(99.9%, Alfa Aesar, Ward Hill, MA), nano-ZrO2 (30~60 nm, Advanced Materials LLC, Manchester, CT), nano-TiO2 (~40 nm, Advanced Materials LLC), nano-ZnO (~30 nm, Advanced Materials LLC) powder, and MnO2 (99.9%, Alfa Aesar) was ball-milled in ethanol for 48 hours using ZrO2 (Tosoh USA, Grove City, OH) ball-milling media. After drying, the mixture was calcined at 750 oC for 2 hr. The calcined powder was then ball-milled with 1 wt% PbO (99.9%, Sigma Aldrich, St. Louis, MO) for 48 hr. After drying, the powder was sieved through 170 mesh sieve. (2) Synthesis of <111> BaTiO3 template: The <111> BaTiO3 template was synthesized by two-step topochemical microcrystal conversion method. (1) <001> B6T17 platelets: <001> B6T17 platelets were synthesized by the reaction between BT and TiO2 (molar ratio: 6:9, excess Ba2+ was added to inhibit the formation of Ba4Ti13O30) in NaCl molten salt at 1150 oC for 1 hour. (2) <111> BT template: <111> BT template was obtained by topochemical reaction between the <001> B6T17 and BaCO3 in NaCl molten salt at 1150 oC for 5 hours. (3) Texturing processing / Templated grain growth: First, the slurry for tape casting process was prepared by mixing synthesized PMN-PZT matrix powder, organic binder (Ferro 73225, Vista, CA) in toluene/ethanol solvent for 24 hours. Then 2 vol% BT templates were dispersed in to the mixture and mixed by magnetic stirring for 24 hours. Next, the slurry was poured in to the reservoir of tape caster and casted through the doctor blade with gap of 200 µm at the rate of 40 cm/min. The dried tape was cut, stacked and laminated at 80 oC under pressure of 20 MPa for 15 min. The laminated green tapes were heated to 400 oC with a heating rate of 0.3 oC/min and maintained for 2 hours for burning the organic binder and then isostatically pressed under 200 MPa for 1 minute at room temperature. Next the samples were embedded in calcined PMN-PZT powders containing 3 wt% excess PbO within a closed crucible and sintered at 1150 oC for 10 hours in flowing O2 (0.2 L/min) atmosphere. Randomly oriented polycrystalline PMN-PZT ceramics were also prepared for comparison by the same procedure without the step of BT template addition. 2. Characterization (1) Crystal structure and texture characterization The crystal structure of textured PMN-PZT was determined using x-ray diffraction (XRD, Bruker D8 Advanced). The degree of pseudocubic <001> texture was determined by Logtering factor method.1 The <111> Lotgering factor f(111) is defined by following equations: f(00l ) = P(111) = P(111) - P0 1- P0 å I (111) å I( hkl ) , P0 = , å I0(111) å I0( hkl ) (S1) . (S2) where å I(111) and å I0(111) are the summation of the XRD peak intensities of the (111) peak in the textured and random samples respectively, and I ( hkl ) and I 0( hkl ) indicate the summation of the XRD peak intensities of all (hkl) peaks in the textured and random samples respectively. We used XRD patterns scanned in 2θ ranging from 20o to 60o for the calculation of Lotgering factor. (2) Microstructure Scanning electron microscope (SEM, FEI Quanta 600 FEG, Philips) was used to analyze the morphology of template and microstructure of the sintered samples. To reveal the grain boundaries and show each individual grain, the fractured cross-section surfaces were etched by HCl+HF solution for 10 sec. After that, the samples were cleaned by the ultrasonic cleaner. Both the fractured cross-section surfaces (fresh) and etched surfaces (etched) were observed. All the samples for SEM were coated with Pt film by sputtering to avoid the surface charging. Piezoresponse force microscopy (PFM, Bruker Dimension Icon) was used to image the ferroelectric domain structures. Conductive Platinum-Iridium silicon cantilevers (SCM-PIT, Bruker) were used for the PFM characterization. (3) Electric Measurement For electrical measurements, the samples with different dimension were polished and electroded with silver on the two faces perpendicular to length (<111> textured) direction. The length/width ratio of 33-mode bars was 3:1. The length/thickness ratio of thickness shear samples was 12:1. The poling along the <111> direction was conducted in silicon oil at 200 oC under a DC field of 15 kV/cm for 5 min followed by field cooling to room temperature. To allow determination of shear piezoelectric properties, the de-electroded samples were reelectroded with platinum on the two surfaces perpendicular to the thickness direction by sputtering. The temperature dependence of dielectric and piezoelectric properties of poled samples were measured as a function of temperature in the temperature range between 25 and 300 oC by using a multi-frequency LCR meter (HP4274A). The polarization vs. electric field curves were measured by using a modified Sawyer-Tower circuit (Precision Premier II, Radiant Technologies Inc.). The properties of piezoelectric materials were characterized in accordance with the IEEE standards (ANSI/IEEE Std. 176-1978)2 by using impedance resonance techniques (HP4194A). From the measured resonance fr and antiresonance fa frequencies, the electromechanical coupling factors and piezoelectric coefficients were calculated. The fr and fa frequencies were determined from the first minimum and maximum impedance peaks in the impedance/frequency scan. The calculations were referred from Ref. 3-4. 1. F. K. Logtering, J. Inorg. Nucl. Chem. 9, 113(1959). 2. The Institute of Electrical and Electronics Engineers, Inc., An American National Standard, IEEE Standard on Piezoelectricity, ANSI/IEEE Std. 176-1987, New York, 1988. 3. S. J. Zhang, C. A. Randall, and T. R. Shrout, J. Appl. Phys. 95 (8), 4291 (2004). 4. S. J. Zhang, E. F. Alberta, R. E. Eitel, C. A. Randall, and T. R. Shrout, IEEE T. Ultrason. Ferr. 52 (11), 2131 (2005).