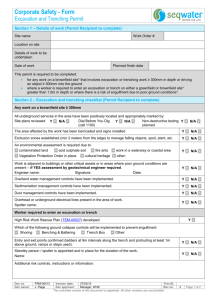

Corporate Safety - Excavation, Trenching & Penetrations

advertisement