Initial review template – production and non-production

advertisement

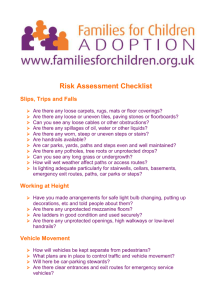

SAFETY CASE ASSESSMENT INITIAL REVIEW – Production or Non Production Installation Safety Case Work Instructions The purpose of initial review is to determine: 1. If the essential components that SCR 2015 Schedules 6 / 7 are present in the submitted safety case; 2. If the submitted case is adequate to give it a good prospect of acceptance in the subsequent assessment process. The initial review is not a consideration of the quality and detailed justifications made-out in the case, this is undertaken later in topic specialists’ individual assessments. IMT Focal Point Inspectors should use this template to record the initial review of a safety case against the requirements of SCR 2015 Schedules 6 / 7. When complete, it should accompany the Assessment Instructions sent to topic specialists. Duty holders should be encouraged to complete the table column labelled “Safety Case Reference” and include appropriate comments to identify the section where the relevant information is to be found within the Safety Case. This will assist Inspectors to quickly locate relevant information, thus making the assessment process more efficient, which is a mutual benefit. For a new case – the initial review should determine if the information required by Schedules 6 / 7 of the regulations is present and where it appears in the case (e.g. chapter or section). For a material change – the initial review should identify which sections of the case have been revised and therefore require assessment. For ‘Material Change’ submissions the duty holder must still submit a full copy of the safety case showing clearly where the proposed revisions are incorporated (Regulation 24(2)). The Initial Review Template complements the guidance to the regulations and topic-specific guidance, standards and good practice. Together with topic-specific templates, it forms part of the complete record of the assessment process undertaken by the Competent Authority. Relevant Guidance APOSC Principles: Factual information Principle 1 The factual information should meet the [SCR15] requirements and provide sufficient detail to support the arguments made in the case GASCET Chapters: 1-4 Assessment of Adequacy In assessing the major accident hazard aspects of safety case submissions it is necessary to determine the adequacy of, inter alia: Hazard identification Risk evaluation Risk management measures [barriers and performance standards] The demonstration of compliance with relevant statutory provisions.… TRIM: 2015/0231007 Revised 25/9/2015 – DRAFT Owner: ED7 Page 1 of 3 SAFETY CASE ASSESSMENT - INITIAL REVIEW - Production or Non Production Installations Safety Case Nonproduction Schedule 7 Production Schedule 6 SCR2015 1 1 2 2 3 3 4 4 5 5 6 6 7 8 7 8 9 Comments to Assist Topic Assessors For Example: Has text changed from the current (previously accepted) safety case. Are there multiple sections that provide information to address the requirements etc. Content is sufficient to proceed to assessment? (Y/N) Name and address of operator / owner operator / owner as approved by DECC/OGA contact address Maximum number of persons on board expected / max / accommodated CMAPP CMAPP to be present in case Summary of worker involvement worker & safety reps involvement Description of the SEMS sufficient content to presume all regulatory requirements have been covered Description of verification scheme (incl. well examination scheme – Well Operators only) sufficient content to presume all regulatory requirements have been covered Matters raised during design notification (Production only) pNAIs and DH response to them Main requirements of design limits to safe operation, compliance with DCR Reg 4 (general integrity) & PSR reg 11 (safe operation of a pipeline), suitability of SECEs. Environmental limitations (Non Production only) environmental / meteorological, seabed/subsoil & location stationing limitations Risks from seabed and marine hazards (Non Production only) seabed / marine hazards for pipelines / moorings / wells / subsea equipment Meaning of Operator – no requirement for information (Production only) 9 10 11 Schedule Detail & Required Content Safety Case Section Reference 10 Plan of location (Production only) meteorological / oceanographic / seabed / subsoil Description of installation primary & secondary structure / plant / layout & configuration / connections to pipelines, installations, wells / transfer means TRIM: 2015/0231007 Revised 25/9/2015 – DRAFT Owner: ED7 Page 2 of 3 SAFETY CASE ASSESSMENT - INITIAL REVIEW - Production or Non Production Installations Safety Case Nonproduction Schedule 7 Production Schedule 6 SCR2015 12 11 13 12 14 15 13 16 17 14 18 15 19 16 20 21 17 22 18 23 19 24 20 Schedule Detail & Required Content Safety Case Section Reference Comments to Assist Topic Assessors For Example: Has text changed from the current (previously accepted) safety case. Are there multiple sections that provide information to address the requirements etc. Content is sufficient to proceed to assessment? (Y/N) Particulars of types of operation capability and actual Particulars of plant and arrangements well control / process safety / containment of hazardous substances / prevention of fire & explosion / protection of environment Description of pipelines (Production only) fluid conveyed / dimensions & layout / max volume / apparatus & works to secure safety Compliance with PFEER 4(1) assessment, measures and arrangements for protection from fire & explosion Particulars of PFEER and MAR (Production only) aspects of fire, explosion, emergency response and management for control of major accident hazards Information relating to the prevention of major accidents resulting in significant / serious damage to the environment potential environmental effects, technical / non-technical measures to prevent, reduce, offset & monitor Plant used and arrangements made to protect persons from hazardous substance & toxic gas Measures taken and arrangements to protect persons from fire, heat, smoke, toxic gas, fumes including: TR, escape routes, means of evacuation, monitoring & control station Maintenance of control systems on evacuation (Production only) arrangements made Description of the internal emergency response arrangements PFEER & OPEP Assessment of oil spill response effectiveness Description of OPRC assessment Particulars of combined operations arrangements for: co-ordinating SEMS, reviewing safety aspects including identification of hazards & assessment of risk, plant used, impacts on installations Other relevant details TRIM: 2015/0231007 Revised 25/9/2015 – DRAFT Owner: ED7 Page 3 of 3

![Case Title - [Safety Case Title] Operator – [Company Name]](http://s2.studylib.net/store/data/015576327_1-35a320172e84be576e8677009be0b1d7-300x300.png)