Guidelines for Full Papers

advertisement

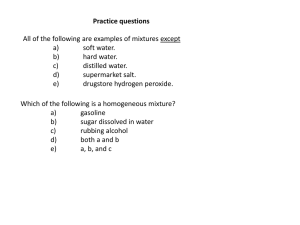

The 9th International Chemical Engineering Congress & Exhibition (IChEC 2015) Shiraz, Iran, 26-28 December, 2015 ----- 5 line Space (Times New Roman 16 pt. Bold)----- Application of Van’t Hoff and Arrhenius equation in determining temperature dependency of butyl oleate ester synthesis using loofa-immobilized Rhizopus oryzae ----- 1 line Space (Times New Roman 16 pt. Bold)----Shabnam Shahhoseyni, Bahram Nasernejad, Farzaneh Vahabzadeh Chemical Engineering Department, Amirkabir University of Technology far@aut.ac.ir ----- 4 line Space (Times New Roman 10 pt. Italic) ----- Abstract Catalytic production of butyl oleate ester from oleic acid and butyl alcohol with use of Rhizopus oryzae (PTCC5174) as a lipase producer fungus was performed in this work, where the fungal cells were immobilized in loofa sponge. The specific activity of the cell-bound lipase of whole cell biocatalyst (loofa- immobilized cells “LIC”) was 0.07 U/mgbiomass . In the present study initial reaction rate and final yield of butyl oleate ester synthesis in four different reaction temperatures, were determined. The temperature dependency of reactions is determined by calculating activation energy at the temperature level of the reaction. Then with using the thermodynamic relationships of Van’t Hoff and Arrhenius, ∆S, ∆H, ∆G and activation energy of esterification reaction were computed. 43.3 Kj/mol , 163.7 j/mol K are anthalpy and entropy respectively, gibbs energy was in range of -3.6 to -8.3 and activation energy of reaction was 18.98 Kj/mol. ----- 1 line Space (Times New Roman 10 pt.) ----Keywords: Rhyzopus oryzae, Loofa, whole cell, Van’t Hoff equation, Arrhenius equation ----- 2 line Space (Times New Roman 10 pt.) ----- Introduction Biotechnological production of fatty acid esters with lipase enzymes has recently drown much attention with respect to the chemical methods. Lipases (glycerol esters hydrolase, E.C.3.1.1.3) have been widely used to produce fatty acid esters that this esters can use for biofuel additive, biosurfactants production [1], aroma and flavor compounds [2,3]. Among these esters, the 1-butyl oleate was useful as a diesel additive, a polyvinyl chloride plasticizer, a water-resisting agent and in hydraulic fluids. Lipase and other enzymes tend to be high in cost due to purification procedures, making the process uneconomical. So an alternative to purified lipase enzyme is to use the enzymeproducing organisms directly as biocatalysts. In this case, intracellular enzymes expressed on the cell wall or membrane is used instead of extracellular enzymes that require extraction and purification from the culture medium. Whole cell biocatalyst can also be immobilized to extent its life. Immobilized cells can be easily handled and make easier the separation of the catalyst from the reaction mixture and its reuse. The main advantages of using immobilized cells are, among others, high yields, easy recovery and reusability of the catalyst [4]. The 9th International Chemical Engineering Congress & Exhibition (IChEC 2015) Shiraz, Iran, 26-28 December, 2015 The thermodynamics of biochemical reactions provide important information on the state of progress in the reaction. Some parameters like Enthalpy, entropy, Gibbs free energy and activation energy of the reactions give us the ability to assess the behavior of reactants in a biochemical reaction, so the experimental measurement of these parameters has very high importance. These thermodynamic parameters could be found with the help of Vent Hoff and Arhnyvs equations. Spontaneity of a reaction determined by its free energy change is useful criterion in measuring thermodynamic parameters influencing the process of the interest. In the present study the equilibrium constant of the butyl oleate ester synthesize with use of the whole cell catalyst (loofa-immobilized Rhizopus oryzae as the lipase producer fungus) was determined on the four different reaction temperature and using Van’t Hoff and arrhenius equation extents of enthalpy and entropy change, gibbs free energy, and Activation energy were determined. Materials and method Microorganism and media: All experiments were carried out using the filamentous fungus R. oryzae (PTCC 5174) as the lipase producer. The strain of Rhizopus oryzae was purchased from “Persian Type Culture Collection (PTCC)” and then was routinely maintained on an agar slant made from 4% potato dextrose agar and 2% agar. Per liter of distilled water, the basal medium contained: polypepton 70 g; NaNO3 1.0 g; KH2PO4 1.0 g; and MgSO4·7H2O 0.5 g. olive oil as sole carbon source was added to the medium at a concentration of 30 g/l. The pH of the medium was initially adjusted to 5.6 and then allowed to follow its natural course [5]. Immobilization of cells: Loofa sponge was used as the immobilization structure for the Rhizopus oryzae fungi in this study. These structures were prepared in the following steps. First the loofa was cut in the form of disks with a diameter of 1.5 cm, boiled in distilled water for 10 minutes and dried at 80 degrees Celsius in an oven. Next, 6 of these disks were put in an Erlenmeyer flask (250 ml) containing 50 ml of the basal medium and after sterilization, spores were inoculated from a fresh slant to the flask. The temperature during cultivation was controlled at 30 degrees Celsius on a reciprocal shaker at 150 rpm for 48 hours. In the final step the LICs were separated from the broth and washed with tap water followed by Acetone and dried under vacuum for 72 hours [6]. Experimental procedure for the enzymatic synthesis: The reactions were performed in screw-capped flasks with a working volume of 10 ml containing tow substrate (oleic acid and butanol) dissolved in n-hexane. The reaction mixture was incubated at different temperature in range of 15-55 C, in presence of tow loofa pieces containing 200 mg of R-oryzae cells with shaking (250 rpm). Analytical methods: Aliquots of the reaction mixture were withdrawn periodically and the residual acid content was assayed by the colorimetric method with use of cupric acetate- pyridine aqueous solution as the color reagent [7]. The absorbance of samples was measured at wavelength of 715 nm using a JASCO V-550 spectrophotometer. The percentage conversion in ester synthesis was based on the amount of acid consumed. The 9th International Chemical Engineering Congress & Exhibition (IChEC 2015) Shiraz, Iran, 26-28 December, 2015 Calculation of thermodynamic parameters: The van't Hoff equation may be derived from the Gibbs-Helmholtz equation, which gives the temperature dependence of the Gibbs free energy. Van’t hoff equation is defined by: From this form of the van't Hoff equation, we see that a plot with lnKeq on the y-axis and 1/ T on the x-axis has a slope given by –dH/ R and entropy will be calculated too. Gibbs free energy also defined by : Arrhenius' equation gives the dependence of the initial reaction rate (v) of a chemical reaction on the absolute temperature T (in kelvins), where A is the pre-exponential factor, Ea is the activation energy, and R is the universal gas constant: A plot of ln(v) versus T −1 gives a straight line, whose gradient and intercept can be used to determine Ea. Results and discussion The effect of reaction temperature on the yield and initial rate of butyl oleate ester synthesis was studied by varying the reaction temperature from 15 to 45 ◦C. Change in reaction temperature can affect the activity and stability of the enzymes, subsequently the rate of reaction. Fig. 1 shows yield and initial rate of butyl oleate ester synthesis at different temperature. The yield and initial rate of the reaction increased linearity with the increase of reaction temperature, up to 35 C and after this point was not significant change. 100 15 25 35 45 60 140 40 Ester concentration (mM) Ester yield (%) 80 20 120 100 80 60 40 20 0 0 0 10 20 30 40 50 60 70 Time (min) 0 100 200 300 400 500 600 700 Time (min) Fig 1. Effect of reaction temperature on the yield and initial rate of butyl oleate ester synthesis Fig. 2 shows the Arrhenius plot made on basis of ln V vs 1/T. The value of activation energy was calculated based from Eq. (2) and the value obtained as 18.89 kJ/mol, Activation energy of 20.2 kJ/mol was reported in the production of fatty acid methyl ester (FAME) from oleic acid and ethanol using Novozyme 435 [8]. The 9th International Chemical Engineering Congress & Exhibition (IChEC 2015) Shiraz, Iran, 26-28 December, 2015 -3.2 3.5 ln V= -2283.58 (1/T) +3.88 ln K= -5210 (1/T) + 19.69 -3.4 3.0 -3.6 ln K ln V 2.5 -3.8 2.0 -4.0 1.5 -4.2 -4.4 0.0031 1.0 0.0032 0.0033 0.0034 0.0035 0.0031 0.0032 0.0033 1/T 0.0034 0.0035 1/T Fig 2. Plots of arrhenius (left) and Van’t Hoff (right) equations The effect produced by variation of temperature on the constant is given by Van’t Hoff’s equation, which permits the estimation of enthalpy changes. The thermodynamic parameters in the process, using the Van’t Hoff equation, Eq. (3), the enthalpy and entropy are 43.3 KJ/mol and 163.7 J/mol/K, respectively. Table 1 summarizes the thermodynamic parameter of esterification reaction to produce butyl oleate ester using LIC. Table 1. Thermodynamic values of esterification reaction _ Temperature (K) ΔG (kJ/mol) ΔH (kJ/mol) ΔS (J/mol K) Ea (Kj/mol) 288 298 308 318 -3.6 -5.3 -6.9 -8.5 43.3 163.7 18.89 Conclusions This study deals with the evaluation of activation energy, entropy, enthalpy and gibbs free energy of reaction involved in the whole cell-catalysed oleic acid transesterification reactions. Loofa immobilized Rhizopus oryzae was used as biocatalyst of butyl oleate ester synthesis. The activation energy for butyl oleate ester synthesis were found to be18.8 Kj/mol, enthalpy and entropy were found to be 163.7 j/mol K and 43.3 Kj/mol respectively and gibbs free energy was found to be in range of -1 to -6 Kj/mol. References [1]Dossat V, Combes D, Marty A. Efficient lipase catalyzed production of a lubricant and surfactant formulation using a continues solvent free process. J Biotechnol ;97:117-24 (2002) [2]Karra-Chaˆabouni M, Zouari N, Frikha O, Sayari A, Gargouri Y. Synthèse d’arˆomes et désacidification d’une huile acide en milieusans solvant. OCL ;9:260–3 (2002) [3] Abbas H, Comeau L. Aroma synthesis by immobilized lipase from Mucor sp. Enzyme Microb Technol ;32:589–95 (2003) [4] Jin, G., Bierma, T. J., Hamaker, C. G., Mucha, R., Schola, V., Stewart, J., Wade, C., Use of a whole-cell biocatalyst to produce biodiesel in a water-containing system. Journal of Environmental Science and Health. Part A, Toxic/Hazardous Substances and Environmental Engineering, 44, 21-28 (2009) [5] Kazuhiro Ban, Masaru Kaieda, Takeshi Matsumoto, Akihiko Kondo, Hideki Fukuda , “Whole cell biocatalyst for biodiesel fuel production utilizing Rhizopus oryzae cells immobilized within biomass support particles”, Biochemical Engineering Journal 8, 39– 43, (2001) [6] S. Sattari, F. Vahabzadeh* and H. K. Aghtaei “performance of loofa-immobilized rhizopus oryzae in the enzymatic production of biodiesel with use of oleic acid in n-hexane medium”, Vol. 32, No. 02, pp. 367 - 376, April - June, (2015) [7] Lowry, R.R., Tinsley, I.J., "Rapid colorimetric determination of free fatty acids", J. Am. Oil Chem. Soc. Vol. 53, pp. 470-472, (1976) [8] G. Trubiano , D. Borio, A. Errazu, ‘Influence of the operating conditions and the external mass transfer limitations on the synthesis of fatty acid esters using a Candida antarctica lipase’, Enzyme and Microbial Technology 40, 716–722, (2007)