The status of this measure should be changed to Under Review.

advertisement

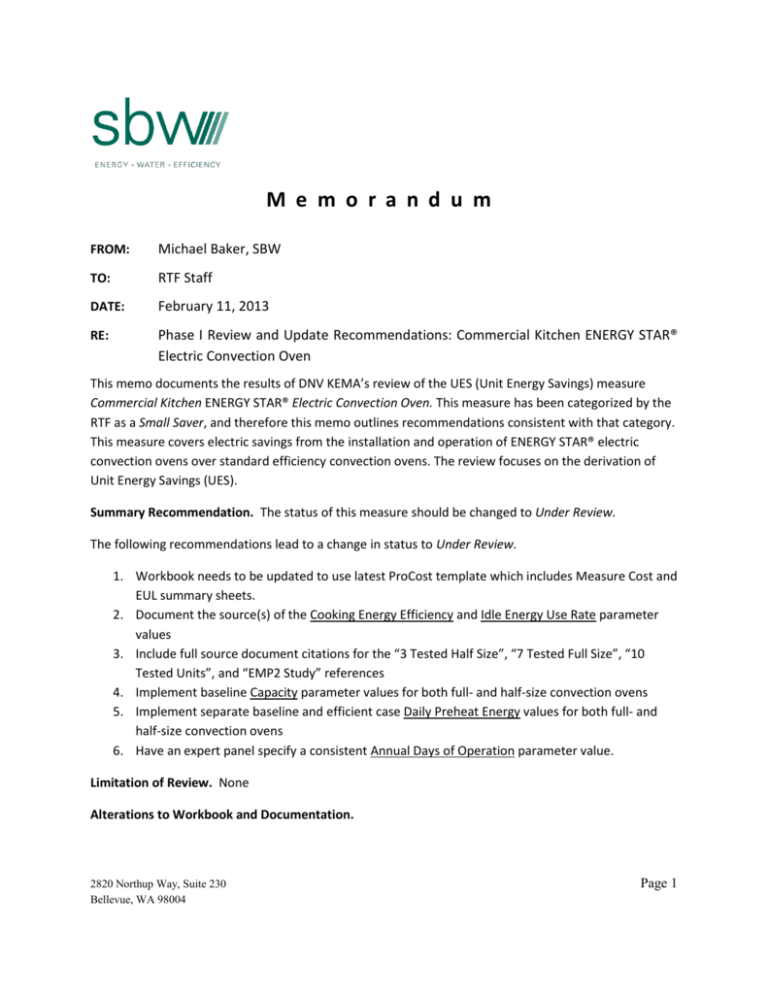

M e m o r a n d u m FROM: Michael Baker, SBW TO: RTF Staff DATE: February 11, 2013 RE: Phase I Review and Update Recommendations: Commercial Kitchen ENERGY STAR® Electric Convection Oven This memo documents the results of DNV KEMA’s review of the UES (Unit Energy Savings) measure Commercial Kitchen ENERGY STAR® Electric Convection Oven. This measure has been categorized by the RTF as a Small Saver, and therefore this memo outlines recommendations consistent with that category. This measure covers electric savings from the installation and operation of ENERGY STAR® electric convection ovens over standard efficiency convection ovens. The review focuses on the derivation of Unit Energy Savings (UES). Summary Recommendation. The status of this measure should be changed to Under Review. The following recommendations lead to a change in status to Under Review. 1. Workbook needs to be updated to use latest ProCost template which includes Measure Cost and EUL summary sheets. 2. Document the source(s) of the Cooking Energy Efficiency and Idle Energy Use Rate parameter values 3. Include full source document citations for the “3 Tested Half Size”, “7 Tested Full Size”, “10 Tested Units”, and “EMP2 Study” references 4. Implement baseline Capacity parameter values for both full- and half-size convection ovens 5. Implement separate baseline and efficient case Daily Preheat Energy values for both full- and half-size convection ovens 6. Have an expert panel specify a consistent Annual Days of Operation parameter value. Limitation of Review. None Alterations to Workbook and Documentation. 2820 Northup Way, Suite 230 Bellevue, WA 98004 Page 1 A sheet called ‘Summary” was deleted from the workbook. This sheet contained a table with measure efficiency, energy consumption, annual savings, incremental cost, TRC B/C, and TRC levelized cost values, which are all represented elsewhere in the workbook. A sheet called “Summary” has been added to the workbook. This sheet describes how measures are identified, lists important constants and their sources, describes the savings estimation algorithm and the associated baseline and efficient case parameters and their sources for each measure and UES component. The cooking energy equation was altered to reference the cells that contain the assumed parameters, instead of having the assumed values of the parameters imbedded in the equation. This allows for automatic computation of the cooking energy savings when altering assumed parameter values in the ‘Convection Oven Assumptions’ table. This change was carried out in cells F8, F12, F17, and F21 of the ‘Methodology’ worksheet. The new equation eliminated a rounding error that slightly exaggerated the cooking energy requirement for the full-size measure type. The impact of eliminating this error is a reduction in full-size convection oven annual savings by two kilowatt-hours The preheat energy equation was altered to reference the cell containing the Annual Days of Operation parameter, instead of having the assumed value imbedded in the equation. This allows for automatic computation of the preheat energy when altering the Annual Days of Operation parameter value in the ‘Convection Oven Assumptions’ table. This change was carried out in cells G8, G12, G17, and G21 of the ‘Methodology’ worksheet. The idle energy equation was simplified to eliminate referring to the Annual Hours of Operation parameter twice. This change was carried out in cells H8, H12, H17, and H21 of the ‘Methodology’ worksheet. The “Hours” headings in the four energy calculation tables of the ‘Methodology” worksheet were changed to “Annual Hours” to more accurately convey the definition of these values. This change was carried out in cells E7, E11, E16, and E20. The measure type description cells for the baseline and post-condition full-size calculation tables of the ’Methodology’ worksheet were mislabeled as “Half-size”. The measure types have been changed to correctly display “Full-size” measure type. The units under the description of the Food Cooked Half-size for the Convection Oven Assumptions of the ‘Methodology’ worksheet were missing the “per day” denominator. The units have been changed to correctly display “(lbs/day)”. The Annual Days of Operation input parameter was added to ‘Convection Oven Assumptions’ table (Cell F26 on the ‘Methodology’ worksheet) and the cell value of 360 days/year is now referenced in the cooking and idle energy equations. A table of baseline parameters from the EMP2, Inc. power point presentation to RTF on Commercial Kitchen Cooking Measures, presented November 6, 2009, was inserted into the ‘Methodology’ worksheet. Recommendations for Updates. The RTF should implement the following recommendations: 1) Workbook Structure and Formulas Page 2 a) Update workbook with latest ProCost template to include Measure Cost and Effective Useful Life (EUL) summary sheets. This deficiency causes the measure status to change to Under Review. 2) Documentation a) Document the source(s) of the efficient case Cooking Energy Efficiency and Idle Energy Use Rate parameter values. The source(s) should have a full source document citation, if available. If the source(s) were not published, provide a description of the source material, a summary of analyses performed on the raw source data, and list a contact for more information. This issue causes the measure to be Under Review. b) A sheet called “Methodology” makes reference to sources that are not presently available. Three sources are referred to as “3 Tested Half Size”, “7 Tested Full Size”, and “10 Tested Units”; these appear to have come from the Food Service Technology Center (FSTC) lab. The other source is referred to as the “EMP2 study”. These sources should have a full source document citation, if available. If the sources were not published, provide a description of the source material and list a contact for more information. This causes the measure to be Under Review 3) Measure Definition a) No changes recommended. 4) UES Savings Estimation Method a) No changes recommended. 5) Input Parameters a) Use different Capacity parameter values for baseline and efficient case full- and half-size convection ovens, since these differ as a function of the technology. The current savings methodology uses the efficient case Capacity values for both baseline and efficient case calculations. Recommend using baseline Capacity values for half- and full-size ovens from a 2012 Pacific Gas & Electric (PG&E, a California utility) work paper on commercial convection ovens1. Those baseline Capacity values are 70 lb/hr for full-size convection ovens, and 45 lb/hr for halfsize convection ovens. The currently used values of 50 lb/hr for half-size and 85 lb/hr for full-size ovens would then only be used in the efficient case calculations. This issue causes the measure to be Under Review. b) Use different Daily Preheat Energy values for baseline and efficient case full- and half-size measure types. The current savings methodology uses the efficient case Daily Preheat Energy values for both baseline and efficient case calculations. Recommend using baseline and efficient case Daily Preheat Energy values for half- and full-size ovens from a PG&E work paper on commercial convection ovens. Those baseline Daily Preheat Energy values are 1.50 kWh for fullsize and 1.0 kWh for half-size, and the efficient case Daily Preheat Energy values are 1.00 kWh 1 Work Paper PGECOFST101 Commercial Convection Oven Revision # 4, June 5, 2012 Page 3 for full-size and 0.9 kWh for the half-size measure type. This issue causes the measure to be Under Review. c) A very minor error that this review identified is an inconsistent Annual Days of Operation value. The cooking and idle energy parts of the energy savings equation use 360 days/year, while the pre-heat part of the equation uses 365 days/year. It is recommended that an expert panel choose a consistent value. This issue causes the measure to be Under Review. Additional Considerations. 1) The ENERGY STAR® Specifications for Commercial Ovens is currently under revision, as is the ASTM Standard Test Method for Performance of Convection Ovens. The exact date of these updates is unclear at the moment; however, the specifications are slated to be finalized by the ENERGY STAR® program by the beginning of fall 20122. The latest publically available draft of the specification update is Draft 2 Version 2.0 Specifications for Commercial Ovens, published July 18, 20123.When this information becomes available the sunset date for this measure should be aligned to coincide with the specification update so that when the new specifications go in to effect, the measure will have its status changed to Under Review. The specification update will likely require measure definition revisions and updates to the UES Savings Estimation Method to account for the new ASTM standard test method that the ENERGY STAR® specifications are based around. Other key variables used in the current savings methodology, such as Daily Preheat Energy, Daily Hours of Operation, the Cooking Energy Requirement (kWh/lb), and Idle Energy Use Rates will also need to be updated. All these changes will require revisions to the Workbook Structure and Formulas. 2 3 ENERGY STAR July 2012 CFS Newsletter The ENERGY STAR® Draft Specification documents are available online at http://www.energystar.gov/index.cfm?c=revisions.commercial_oven_spec (Last accessed August 3, 2012) Page 4