View/Open - University of New Mexico

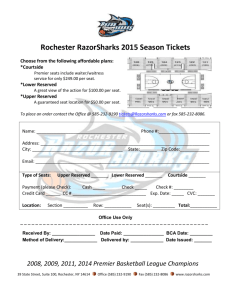

advertisement

Research in Progress: Review of Tractor Seating Issues Related to Ergonomics of Difference C.S. Wilhite, University of New Mexico W.E. Field, Purdue University Paper Presented at the International Society of Agricultural Safety and Health Annual Conference 2014 June 24, 2014 Omaha, Nebraska Funded Research: Southwest Center for Agricultural Health, Injury Prevention, and Education, NIOSH-2U540H007541, CFDA# 93. 262 Financial Interest Disclosures: C. Wilhite-No other disclosures W. Field-No other disclosures 1 Abstract Agricultural machinery technology is rapidly evolving, but seating, seat materials, and management of seated pressure has remained largely unchanged, and may not conform to the needs of most seated individuals who vary by size, weight, posture, gender, or health status (ergonomics of difference). People with ergonomics of difference, including those with disabilities, find they have to incorporate after-market accommodations to try to fit themselves to the seating conditions, which changes the dynamics of the seating system in ways that have not been researched to determine the risk/benefits. The paper explores problems and issues in seating, research in progress, and concludes with recommendations to increase the range of adaptability and customization of agricultural seating. 2 Introduction According to ergonomist Karl Kroemer (2006), the majority of product designs for industry, workplace, homes, and jobs are based on data (anthropometrics) for average human size and abilities, when in fact; many people vary from the average because they have ergonomics of difference. Ergonomics of difference include factors such as size, gender, age, disability, body shape, and health status that vary for each person over the natural course of time (Kroemer, 2006, p. 1-6). Kroemer states that a majority of people will vary from “normal” in one or more ways. In absence of design for human variance at the forefront of product design, accommodations for ergonomics of difference must be considered afterward (or aftermarket) in order to enable an individual’s participation in tasks and activities. Such alterations may perturb subtle or large effects to the original product’s design integrity, with potential for both harm and/or benefit. The effort to accommodate ergonomics of difference as an aftermarket strategy is hampered by lack of accepted standards or knowledge base to support modifications. Many examples of modifications to accommodate disability are found in the work of USDA grant-funded AgrAbility Projects, including the ingress/egress of the agricultural machinery operators’ platform using an aftermarket commercial manlift (or, in some instances a homemade lift), versus factory designed stairs or ladders (Wilkinson & Field, 1987; Yoder, Stoller, & Field, 2000). Once seated in the agricultural machine, additional accommodations are often necessary to address individual variance regarding posture, mobility, strength, size, reach, control, and seating support needs. In addition, modifications may be needed to allow the operator to communicate with co-workers, and adequately monitor attached equipment and the space immediately surrounding the machine (Yoder, Stoller, & Field, 2000). 3 The seating support needs of individuals with spinal cord injuries or similar neurological health issues are of special concern because conditions of paralysis create changes in sensation, motor function, circulation, and tissue health that can pre-dispose the person to skin tears, lacerations, and pressure-related ulcers (Minkel, 2000). Tissue injuries range from minor epithelial blanching to deep tissue and non-stage-able decubitus ulcers that involve muscle and bone (National Pressure Ulcer Advisory Panel-NPUAP, 2009). Severe decubitus ulcers can result in costly medical and rehabilitation treatment, or result in death of the individual (Hunter & Sakar, 2011). Often individuals with a spinal cord injury operating an agricultural machine will select a seat cushioning material of their preference (typically a wheelchair cushion of gel, foam, fiber, or air inflation), or whatever is at hand, to use as a support surface on top of the seat. The use of the wheelchair cushion accommodation presumes that the original seating provided by the manufacturers, often a contour foam seat, is insufficient to distribute pressure at the seat interface and may predispose the operator with spinal cord injury to a pressure-related skin injury; and secondly, the selected aftermarket cushion is sufficient to prevent a pressure-related skin injury. Testing the accuracy of such presumptions is necessary and urgent. Review of Literature A scoping review of the literature over a broad area of research was conducted. The scoping enables the broad mapping of an issue and if there are gaps in the research record (Armstrong, Hall, Doyle, & Waters, 2011). This review scoped the fields of agricultural machinery seating, ergonomics, wheelchair seating, spinal cord injury, pressure and decubitus ulcer to produce a sufficiently broad picture of the issues produced in the introduction, and to help identify research gaps, if any, so that researchable questions could be created to test the 4 above presumptions. Databases used in the scoping review search included: PubMed, CINAHL, ProQuest, and the ASABE Technical Library. Search terms included: agricultural machinery seat*, tractor seat*, seat standards, seat vibration, seat design, seat interface, wheelchair seat*, wheelchair support surfaces, wheelchair seat standards, wheelchair seat interface, pressure mapping, spinal cord injury, pressure ulcer, and decubitus ulcer. The terms were used in various combinations to undercover as many articles as possible strongly relevant to seating. The search produced approximately 90 articles in the area of agricultural machinery seating issues. Hundreds of articles were available in relation to spinal cord injury and decubitus ulcer, and a preliminary review aided in delimiting these to about 50 articles related to aspects of decubitus/pressure ulcers, about 53 articles related to spinal cord injury sequelae, and approximately 12 articles on the use of pressure mapping instrumentation in wheelchair seating assessment. In addition, additional evidence-based information was gathered from reliable entities such as the National Pressure Ulcer Advisory Panel (NPUAP), International Standards Organization (ISO), and National Institute on Disability and Rehabilitation Research (NIDRR). The complete bibliography is available upon request from the first author. Issues in the literature. Agricultural engineering, ergonomists, and the wheelchair seating fields share a central concern for the health effects of seating on the human body. Various standards for testing the acceptability of tractor seating are provided by ASABE and ISO (e.g. ASABE/ISO 5007:2003; ASABE/ISO 5008:2002 w/Cor. 1; ISO 10326-1:1992, 9.1). There are also ISO standards for wheelchair seating support interfaces (e.g. ISO 16840-1; ISO 16840-2). However, the extent of translation of knowledge from one field to other is relatively unexamined. For example, a primary seating support for an individual seated in a tractor, beyond the seat materials and contour seat design, may be a seatbelt which is required on nearly all tractors 5 equipped with Roll-over Protective Structures (ROPS). The primary purpose of the seatbelt is for protection and safety within the dynamic system of the tractor environment. In addition, a major objective in agricultural machinery seating design is to decrease the transmission of whole body vibration, which can produce back pain, cumulative trauma, and permanent injury on operators (Balasubramanian, Burks, Lehtola, & Lee, 2006). The majority of seating interventions focus on the suspension of the seat, the cab, and profile of the seat in ways that dampen vibration forces (Donati, 2002). All current environmentally controlled tractor cabs are isolated from the chassis of the tractor to reduce the transmission of vibration and shock to the operator. Conversely, the primary seating supports for an individual with a spinal cord injury may include lap belt, wedges, lateral supports, trunk harness, and head supports that comprise a system of support that promotes safety, comfort, health, attributes of pressure distribution, and facilitates function. Researchers in the field of wheelchair seating supports consider forces primarily in the seat interface (e.g. shear, moisture, temperature, pressure) and individual physiology (e.g. circulation, integument, sensation) occurring between the cushion, skin, and bony anatomy (Gefen, 2007; Eslami, Saadat, Arejan, Vaccaro, Ghodsi, & Rahimi-Movaghar, 2012; Linder-Ganz, Shabshin, Itzchak, Yizhar, Siev-Ner & Gefen, 2008). Only one article was found that demonstrated some overlap between agricultural and wheelchair seating fields of research. The article in an ergonomics journal (Hostens, Papaionou, Spaepen, & Ramon, 2001) looked at seated pressure on four different contour foam-based agricultural machinery seats. The foam seats were compared to an air-based cushion system with a grid of multiple individual air blocks. The air cushion was customized to ensure air blocks were placed underneath the ischial tuberosities (IT) and the air blocks varied in size to conform 6 to the individual anatomy of the test subject. Ten healthy male subjects took part in the protocol to acquire data on each of the seating conditions under static conditions using repeated measures. The foam seats indicated mean pressures over or approaching 200 mmHg under each IT, while the air cushion halved those numbers and were statistically significant. Pressures above 30mmHg are estimated to be sufficient to occlude capillaries in the human body, although Gefen (2007) has more recently estimated a range closer to 60-90mmHg around the IT as problematic if pressure is unrelieved for greater than one hour. In discussion, Hostens, Papaionou, Spaepen, and Ramon (2001) recommended that a seating system should provide postural control and pressure relief, however, the foam contour seats used in the study did not meet both conditions. The air-based cushion allowed maximal contouring and individualized customization. The study referenced 20 articles, with six of them from the wheelchair or rehabilitation engineering field. Lastly, there has been no known research on the effects of modifications needed by an operator with a spinal cord injury and the zone of protection provided by current ROPS standards for agricultural tractors (ASABE, 2014). In addition, no studies in wheelchair seating were uncovered in this scoping review that subjected users to the extreme conditions of terrain and forces like those found in tractors under field conditions. The scoping review confirmed there is a large gap in the research record pertaining to accommodations for ergonomics of difference in agricultural machinery seating, although significant amounts of work has been done on the dynamics of tractor systems, operation, seating, and the effects of forces on the average human operator. Equally, there are gaps in the literature for wheelchair seating support surfaces, especially when exploring exposures to 7 vibration and other robust forces that occur beyond laboratory or sidewalk wheeling of cushion users. The gap in literature and lack of evidence creates difficulty for those working in AgrAbility Projects to accommodate ergonomics of difference for individuals with disabilities. Supported by letters from National AgrAbility at Purdue University, state AgrAbility Projects, and farmers with spinal cord injury, funding from the Southwest Center for Agricultural Health, Injury Prevention, and Education allowed the first author to undertake a feasibility study to open a line of research to address the gap. Purpose The purpose of the study was to measure seated pressure on an average original equipment foam contour tractor seat, with and without intervention wheelchair cushions (representing an aftermarket accommodation), using subjects with paraplegia creating sensory and motor loss in the lower extremities. The University of New Mexico-Health Sciences Center Institutional Review Board (#13-129) approved the research. Methods Sample: The study sample of eight individuals (5 Male, 3 Female) was a convenience sample drawn from individuals with paraplegia who use wheelchairs with specialized cushions from the University of New Mexico Health Sciences service area who were able to give consent, including individuals from rural and agricultural communities. Subject inclusion criteria included adults with paraplegia who do not currently have an unhealed pressure ulcer or decubitus ulcer on the posterior or current underlying health issues that would compromise the integumentary system. Exclusion included people with unhealed/unstable decubitus ulcers, persons unable to 8 give consent, or inability to aid in their own transfer to/from the study platform. All subjects were capable of driving automobiles, vans, or trucks with adaptations for access and operation. Instruments: Braden Scale: Subjects were screened using the Braden Scale (Bergstrom, Braden, Laguzza, & Holman, 1987) a well-known scale used to predict pressure sore risk. The scale is a one page questionnaire on which respondents estimate their mobility, ability to perform pressure relief, level of sensory impairment, exposure to moisture, and nutritional intake. Answers correspond to a numerical scale, which predict risk for pressure ulcer. Scores less than twelve represent high risk, and scores over twelve represent lower risk. A high risk Braden Scale score (12 or less) did not necessarily exclude subjects from the sample, but served as an additional protection to the human subject who could benefit from educational materials to reduce their risk score or who needed to make an informed decision on whether or not to participate in the study based on decubitus ulcer risk. FSA Pressure Mapping System and FSA4.1.001 Software: The primary instrument used was a pressure mapping system widely used in the assessment of wheelchair seating surfaces manufactured by Vista Medical, Inc. and designed to discern relative pressure levels of a mass on a support surface. The pressure sensors in the FSA array are accurate to +/- 20%. The pressure mapping equipment consists of a laptop computer running pressure mapping software, a peripheral cable, and sensor mat. The sensor mat contains numerous sensors capable of measuring mmHg (or in Newton and Psi) in discrete units and groups of selected sensors, especially around bony prominences. The graphical display provides a real-time observable picture of sensor measurement ranging from blue (low pressure) to green (moderate pressure) to red (very high pressure). The FSA can also record pressure across real time through video and provides the average pressures of each trial at selected intervals through capturing a graphic 9 image. For example, the color red would indicate that pressure exceeds the body’s ability to reperfuse the tissue with blood, putting them at risk for tissue injury. The mathematical data captured from the instrument can be converted into statistical information. Interventions: The equipment necessary to perform the research interventions included a new Sears manufactured contour tractor seat with seatbelt, one new 2 inch thick reticulated foam wheelchair cushion, and one each of a new low, mid, and high profile ROHO® Quadtro air cushions designed as wheelchair support surfaces. Lab & Apparatus: The research was conducted in a lab environment at the university with an average temperature of 72, and humidity of 20%. A research platform was constructed that allowed mounting of the tractor seat on top of a low-profile air suspension system (Figure 1.). A deep cycle battery operated the air suspension. The platform floated, but the excursion of the platform was limited by four springs. A half-dome inflated therapy ball was placed underneath the platform and was situated under the seats designated center of gravity. The platform could be locked into place and was accessible by wheelchair ramp. Tilt of the platform was limited to ten degrees fore/aft, and side to side. In the unlocked position, the platform could be perturbed, tilted, jostled, and vibrated in four directions while the subject steered during a looped video of plowing a field. 10 Figure 1. Procedures: After consenting to participate in the study, subjects were safely transferred from the platform to the tractor seat. Depending on the randomization of the cushion order, the subject transferred to the tractor contour foam seat or one of the other four cushions (two inch reticulated foam cushion, low-mid-or high profile ROHO® Quadtro cushion). Once the transfer was completed, the FSA pressure mat was placed underneath the subject. Every effort was made to smooth the folds in clothing and wrinkles of the FSA mat to allow only the natural contours of the body to rest on the surfaces of the cushion and minimize the potential for inaccurate sensor readings. The subjects used the available seat belt. Additional postural adjustments were made (e.g. raising armrests) and adding support underneath the feet after the air suspension was inflated to ensure contact of the feet for weight bearing. The seatback was kept in an upright position (although Subject Five reclined the seat approximately five degrees for comfort), and the fore/aft control was used to slide the seat forward or back so the subject could comfortably reach the steering wheel. Depending on the cushion intervention, the subjects settled on the seats for fifteen minutes (foam) or five minutes (air cushions). Settling allows the subject to immerse fully into the seating material and maximize contact between the body and the seat. The deformation of foam takes longer to accomplish than 11 the air cushion envelope of neoprene rubber. After settling, the platform was unlocked. The platform was perturbed for one minute each on the left, right, back, and front. Pressure map images and data were collected at each interval. This procedure was repeated for each cushion condition, resulting in five different sets of data. The FSA system was operated by a consultant physical therapist with 25 years of experience in pressure mapping for wheelchair seating interfaces and customization of seating, and is an acknowledged expert in seating issues for people with disabilities. Results The research procedures produced data of the independent variable of five different seating conditions with a series of single-subjects, using repeated measures (Portnoy & Watkins, 2000). Each single subject operated as their own control, thus strengthening internal validity of results, and multiple single subjects strengthens the rigor of the research and confidence in results (Des Jarlais, et al., 2004). The dependent variable was represented by the pressure sensors registering pressure, and the outcome was the pressure image graphics recorded in real time at different intervals. For this presentation, only the images will be discussed as an input to making clinical judgments about the seating situation for each individual. All the produced images were transformed using FSA software. Sensor readings under 5mm Hg were eliminated from the image, which are considered less reliable measures by the manufacturer of the sensor mat. Numerical data is still under analysis. Demographics of participants are in Table 1 and exemplars of results for each subject in the study are found in Figures 2-9: Images are oriented so that the top of the image shows the rear of the seat, and bottom of image is the front of the seat. Therefore, left and right sides are reversed. 12 Table 1. Demographic information. Subject Age Gender Height Weight (inches) (lbs.) Level of Lesion One 35 M 73 280 C7-Incomplete Two 32 M 70 160 C4-Incomplete Three 58 F 64 125 T8-Complete Four 28 M 73 190 Cerebral Palsy-Paraplegia Five 52 M 70 145 T12-Incomplete Six 56 M 65 198 T4- Complete Seven 56 F 64 190 T12-Incomplete Eight 59 F 67 170 T12-Incomplete Figure 2. Subject One Comparisons on Sears Contour Foam Tractor Seat. Contour tractor seat (settle). Contour tractor seat (completion). Subject One (Figure 2.) shows the subject on the foam contour tractor seat after settle. The settle image on the left shows a relatively benign map with the higher pressures represented in green (range of 69-107 mmHg). The image on right is the endpoint of the perturbation period. 13 The image reveals a number of sensors reading in the high-pressure range (yellow and red, 110190mmHg). The areas of high pressure seen in this image were most likely caused by shearing between the seated subject, the sensor map, and the seat. The shearing resulted in an accumulating ridge of pressure as the map wrinkled beneath the excursion of the subjects bottom on the seat, accounting for the red areas on the map. Figure 3. Subject One Comparisons on Hi-Profile ROHO® Quadtro Cushion. Hi-Profile ROHO® (settle) Hi-Profile ROHO® (completion) Figure 3 images compare the high profile air cushion before and after perturbation. The image on the left represents a map with some low to moderate pressures in green around both IT with peak pressures of 84 mmHg on the right IT, and 86 mmHg on the left IT. Visually, the mass of the subject appears well distributed across the cushion, representing good immersion and seat contact. The image on the right was taken after the final platform perturbation. In this image, the peak pressures have diminished under the sacrum and both IT, but there may be less surface contact. As compared to images in Figure 2, the use of the high profile air cushion would be preferable to the contour foam tractor seat alone. 14 Figure 4. Subject Two Comparisons on Sears Contour Foam Tractor Seat. Contour Seat (settle) Contour Seat (completion) Subject Two demonstrates higher-pressure readings before and after platform perturbations on the contour foam tractor seat. The image on the left represents the settle condition with peak pressures of 180 mmHg underneath each IT. After perturbation of the platform, the pressures have diminished to approximately 160 mmHg for right IT, and 156 mm Hg for left IT. Notice the geographic migration of the IT areas by approximately 1-1.5 inches from the back of the seat toward the front when comparing left/right images, and a slight shift to the right. Possible cause for the migration could represent shear, or the volitional effort of the subject to re-adjust seat position. Maintaining or regaining trunk stability and balance was a recurring need by the Subject Two (C-4 tetraplegia, incomplete). 15 Figure 5. Subject Two Comparisons on Hi-Profile ROHO® Quadtro Cushion. High Profile ROHO® (settle) High Profile ROHO® (completion) Visual inspections of Subject Two’s settle image show high-pressures of 167 mmHg under the left IT, and 165 mmHg under the right IT. The settle image also shows the pelvis is slightly rotated forward on the right, which conforms to the hands on observation of the researcher. After platform perturbations were completed, pressure under the IT’s have diminished to a peak of 106 mm Hg under the left IT. However, note that the subject appears to be displacing more body weight on the left versus right side in the completion image. Clinical considerations for seating may need to include additional seating supports for the individual with tetraplegia. Visual inspection of the images tends to support selection of the high profile air cushion over the contour foam tractor seat. 16 Figure 6. Subject Three Comparisons on Sears Contour Foam Tractor Seat. Contour Seat (settle) Contour Seat (completion) The settle image for Subject Three, a female, represents peak pressures at 168 mmHg under the right IT and 109 mmHg under the left. At completion, the left and right IT have migrated forward approximately 1.5-2 inches and shifted to the left. Pressures of 195 mmHg are observed under the left IT, and 83 mmHg under the right IT area. 17 Figure 7. Subject Three Comparisons on Hi-Profile ROHO® Quadtro Cushion. High-Profile ROHO® (settle) High-Profile ROHO® (completion) Subject Three images on the high profile air cushion show peak pressure readings of 82 mmHg under the left IT and 58 mmHg under the right IT during settle. After completion, the left IT reads 62 mmHG, and right is 41 mmHg. The images show relatively no migration of the IT and Sacrum. Clinical observation would support the use of the high profile air cushion over the contour foam tractor seat alone. 18 Figure 8. Subject Four Comparisons for Contour Foam Tractor Seat. Contour seat (settle) Contour seat (completed) Subject Four’s image on the left shows the seated pressures at settle, and image on the right was recorded after completion of perturbations. The image on left shows a peak pressure under the left IT of 103 mmHg, and 55 mmHg under right IT. The overall map is benign. The image on the right represents shearing on the seat, which shows as a ridge of high pressure under the seat and thighs. Subject Four has also migrated slightly to the rear of the seat and to the right edge of seat. Figure 9. Subject Four Comparisons on Hi-Profile ROHO® Quadtro Cushion. High-Profile ROHO® (settle) High-Profile ROHO® (completed) 19 Subject Four in left and right images shows a good distribution of the seated pressure with no areas of moderate or high-pressure areas evolving at settle or completion. The subject is essentially seated in the same area, with very little or no migration. Visual comparison of Figure 8 to Figure 9 would support recommending the high profile air cushion over the contour foam tractor seat. Figure 10. Subject Five Comparisons on Contour Foam Tractor Seat. Contour Seat (settle) Contour Seat (completed) 20 Subject Five demonstrates a very consistent profile from settle to completion and no high pressures above 80 mmHg are found on the settle image, and none over 95 mmHg on the right image. Figure 11. Subject Five Comparisons on Hi-Profile ROHO® Quadtro Cushion. High-Profile ROHO® (settle) High-Profile ROHO® (completed) The images obtained for Subject Five on the high profile air cushion demonstrate overall lower pressures than on the contour foam tractor seat. The highest peak pressure on the settle image is 52 mmHg, while the highest pressure after completion is 47 mmHg. Some migration toward the rear of the seat occurred on the completion image. Potential causes for the migration could be from the person re-adjusting in the seat, or from some small amount of shear. In comparing Figure 10 and 11, the high profile air cushion shows the lowest pressures. 21 Figure 12. Subject Six Comparisons on the Contour Foam Tractor Seat. Contour Seat (settle) Contour Seat (completed) Subject Six’s images reveal concerning high-pressure areas on the contour foam tractor seat, at settle and at completion. On the settle image, a peak pressure of 156 mmHg is shown for the right IT and 191 mmHg for the left IT. After completion, peak pressures of 190 mmHg are found under each IT. In addition, notice the subject has a noticeable pelvic rotation toward the right. Physical examination confirmed the rotation, along with pelvic obliquity (right side higher than left). 22 Figure 13. Subject Six Comparisons on Hi-Profile ROHO® Quadtro Cushion. High-Profile ROHO® (settle) High-Profile ROHO® (completed) Subject Six demonstrates fewer high pressures and greater immersion into the high profile air cushion surface. The highest recorded pressure at settle was 102 mmHg, and 106 mmHg at completion. Compared to Figure 12, the high profile air cushion appears preferable to the contour foam tractor seat. Figure 14. Subject Seven Comparisons on a Contour Foam Tractor Seat. Contour Seat (settle) Contour Seat (completed) 23 Images collected from Subject Seven on the contour foam tractor seat demonstrate areas of high pressure underneath the IT at settle and conclusion. At settle, peak pressure under the right IT is 190mmHg, and 189 mmHg. At completion, a high-pressure ridge has developed with pressures over 190 mmHg recorded under both IT, and most likely represent some frictional force in the seat interface. No geographical migration appears to have occurred. Figure 15. Subject Seven Comparisons on Hi-Profile ROHO® Quadtro Cushion. High-Profile ROHO® (settle) High-Profile ROHO® (completed) Subject Seven’s pressures have greatly reduced at settle and completion. On the image at settle, a peak pressure under the left IT is recorded at 130 mmHg, and 83 mmHg after completion. When comparing Figure 14 images to Figure 15, it appears the high profile air cushion is performing better at distributing pressure. 24 Figure 16. Subject Eight Comparisons on Contour Foam Seat. Contour Seat (settle) Contour Seat (completed) Subject Eight’s pressures at time of settling are 77 mmHg under the right IT and 49mmHg under the left IT. After completion, pressures are 64 mmHg under the right IT and 29 mmHg under the left IT. Overall, the seat conditions appear acceptable. Figure 17. Subject Eight Comparisons on Hi-Profile ROHO® Quadtro Cushion. High-Profile ROHO® (settle) High-Profile ROHO® (completed) 25 Subject Eight’s settle and completion values for pressure are close to Figure 16. It is possible either seating condition would be acceptable based on images alone. Ultimately, further clinical measurement and further trials between the seating conditions could confirm if both seating conditions remained acceptable. Summary of Data. Seven out of eight subjects demonstrated better distribution of pressure, minimal migration, and better immersion with the high profile air cushion. One subject appeared to have acceptable outcomes on both seating conditions. The data shared here represents the extreme poles of the seating interventions, and intermediate seating conditions were not provided as examples. Further comparisons will demonstrate how intermediate conditions provided by the two-inch foam cushion, low profile air cushion, and medium profile air cushions worked for a few, but not all subjects. Only the high profile cushion worked for all subjects. Limitations of Research Several limitations must be acknowledged. First, data gathered in this preliminary research were collected under laboratory rather than field conditions. Conditions under which an operator of an agricultural machine may be exposed would be substantially different, and in most cases, be highly unpredictable and harsh. Second, under field conditions subjects would be exposed to much higher ranges of ambient temperatures, humidity, and a wider range of irregular whole body vibration and acceleration forces, which could significantly influence outcomes. In addition, additional research is needed to assess the efficiency of pressure mapping methods under field conditions in order to ensure the reliability of captured data. Another limiting factor may be the use of only one seat design. Seating configurations within the industry vary considerably and differ in shapes, cushioning material, coverings, and 26 load capacities, design of armrests, and ability to rotate to allow for easier rear viewing. Some of these variables may contribute to different pressure readings, especially under field conditions. Other limitations include: Limited sample size; non-randomized subjects. The researcher is a new investigator; researcher not blind to the research. Subjects did not perform repeated trials on the same intervention cushions, which would have strengthened results. Variations in clothing and clothing wrinkles, as well as the pressure map wrinkling could have affected the reliability of the numerical data. Variations in adjusting the air pressure in the ROHO® Quadtro cushions could have affected the data through over or under inflation. Repeated trials on the same cushions could have ameliorated this effect on the data. Individual factors of subjects could also have affected the data, such as the use of abdominal binders, adult briefs, catheter tubing, or feminine hygiene pads. Other variables pre-disposing to decubitus ulcer not measured at the seat interface (i.e. temperature, moisture, tissue oxygenation). Discussion Application to Field Research. The feasibility study tested the presumptions of whether a contour foam tractor seat would demonstrate unacceptable pressure distribution for people with spinal cord injuries compared to four other seating conditions using wheelchair cushions to accommodate ergonomics of difference. When comparing the contour foam tractor seat to a high profile air cushion in eight examples, the data confirms the presumptions are correct. Further analysis is warranted and replication is necessary. 27 Agricultural machinery is rapidly evolving, but seating, seat materials, and management of seat pressure has remained unchanged or under studied over the past decade. Current product design of seats may not conform to a majority of individuals who vary by size, weight, posture, gender, disability, or health status. Aftermarket accommodations like air cushions demonstrate positive reduction of seating interface pressures under laboratory conditions, but the application of an aftermarket cushion may change the seating system in ways that have not been empirically proven safe and effective, especially under field conditions. There have also been changes in anthropometric data of operators that may not be included in more recent seat designs. This includes physical characteristics associated with aging, increased number of female operators and the physical mass of operators. For example, it is not uncommon to find operators who weigh in excess of 300 pounds attempting to operate from a seat designed for someone weighing 150-225 pounds. The authors address the following questions to the field of agricultural health and safety, ergonomics, industrial hygiene and agricultural and bio-systems engineering: 1. Are there practical limitations on how much front-end design can accommodate the variances involved in ergonomics of difference (e.g. weight, gender, size, postural asymmetries, and disability)? 2. What new materials, structures, contours, and dimensions can be incorporated into front-end design to widen the variance for ergonomics of difference? 28 3. What should be the role of aftermarket and custom design solutions that “fit” into existing front-end design? What research needs to be performed to ensure aftermarket solutions are effective in resolving seating issues, without creating other problems? 3. What body of knowledge and standardization of process needs to be developed for recommending aftermarket accommodations for people with ergonomics of difference? 4. Who needs to perform the work (i.e. designers, engineers, ergonomists, researchers, occupational health nurses, and others)? Will the work be performed in isolation or best performed through multi-disciplinary teams? 29 References Armstrong, R., Hall, B. J., Doyle, J., and Waters, E. (2011). Cochrane update: ‘Scoping the scope’ of a Cochrane review. Journal of Public Health, 33(1), 147-150. doi: 10.1093/pubmed/dr015 Balasubramanian, K., Burks, T. F., Lehtola, C. J., & Lee, W.S. (2006). Shock and vibration data acquisition system for off-road vehicle operator health and safety assessment. Journal of Agricultural Safety and Health, 12(4), 293−313. Bergstrom, N., Braden, B. J., Laguzza, A., & Holman, V. (1987). The Braden Scale for predicting pressure sore risk. Nursing Research, 36(4), 205-210. Retrieved from http://www.ncbi.nlm.nih.gov/pubmed/3299278 Des Jarlais, D. C., Lyles, C., Crepaz, N. (2004). Improving the reporting quality of nonrandomized evaluations of behavioral and public health interventions: The TREND statement. American Journal of Public Health, 94, 361-366. Donati, P. (2002). Survey of technical preventative measures to reduce whole body vibration effects when designing mobile machinery. Journal of Sound and Vibration, 253(1), 169183. doi:10.1006/jsvi.2001.4254 Eslami, V., Saadat, S., Habibi-Arejan, Vaccaro, A. R., Ghodsi, S. M., & Rahimi-Movaghar, V. (2012). Factors associated with the development of pressure ulcers After spinal cord injury. Spinal Cord, 50, 899–903. doi.org/10.1038/sc.2012.75 Gefen, A. (2007). The biomechanics of sitting-acquired pressure ulcers in patients with spinal cord injury or lesions. International Wound Journal, 4(3), 222-231. Hostens, I., Papaioannou, G., Spaepen, A., & Ramon, H. (2001). Buttock and back pressure distribution tests on seats of mobile agricultural machinery. Applied Ergonomics, 32, 347-355. Retrieved from Elsevier at http://www.elsevier.com/locate/apergo Hunter, I. A., & Sakar, R. (2011). Managing pressure sores. Surgery, 29(2), 518-522. Kroemer, K. H. E. (2006). Extra-ordinary ergonomics: How to accommodate small and big persons, the disabled and elderly, expectant mothers, and children. New York, NY: Taylor & Francis. Linder-Ganz, E., Shabshin, N., Itzchak, Y., Yizhar, Z., Siev-Ner, I., & Gefen, A. (2008). Strains and stresses in sub-dermal tissues of the buttocks are greater in paraplegics than in healthy during sitting. Journal of Biomechanics, 41, 567–580. doi.org/10.1016/j.jbiomech.2007.10.011 Minkel, J. L. (2000). Seating and mobility considerations for people with spinal cord injury. Physical Therapy, 80(7), 701-709. Retrieved from http://ptjournal.apta.org 30 National Pressure Ulcer Advisory Panel (2009). International guideline: Prevention of pressure ulcers quick reference guide. Retrieved from http://www.npuap.org Portnoy, L. G., & Watkins, M. P. (2000). Foundations of clinical research: Applications to practice (2nd ed.). Upper Saddleback, NJ: Prentice-Hall. Vista Medical. (2022). User manual for Boditrack and FSA Systems (1st ed.). Winnipeg: Vista Medical, LTD. Wilkinson, T. L. & Field, W.E . (1987). Modified agricultural equipment: Agricultural manlifts for farmers and ranchers with physical handicaps. West Lafayette, IN: Breaking New Ground. Yoder, A., Stoller, N., & Field, W.E. (2000). Plowshares #8: New concepts in lift attachments for tractors and combines. West Lafayette, IN: Breaking New Ground. 31