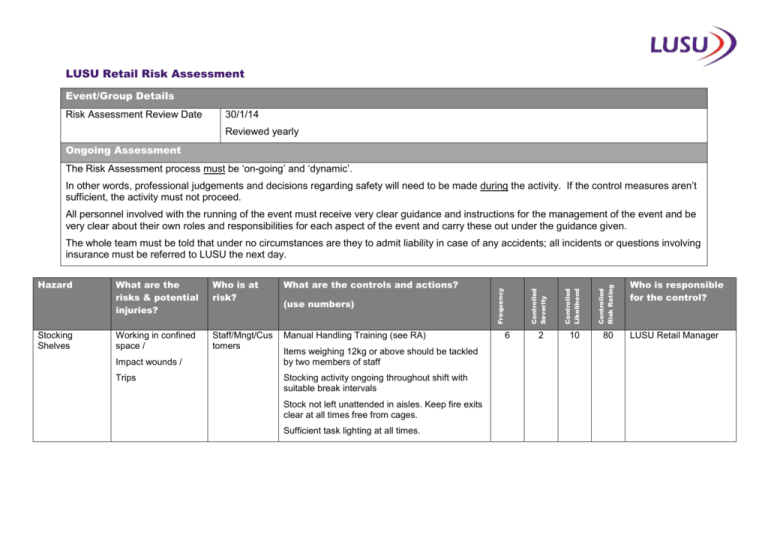

Who is at risk?

advertisement

LUSU Retail Risk Assessment Event/Group Details Risk Assessment Review Date 30/1/14 Reviewed yearly Ongoing Assessment The Risk Assessment process must be ‘on-going’ and ‘dynamic’. In other words, professional judgements and decisions regarding safety will need to be made during the activity. If the control measures aren’t sufficient, the activity must not proceed. All personnel involved with the running of the event must receive very clear guidance and instructions for the management of the event and be very clear about their own roles and responsibilities for each aspect of the event and carry these out under the guidance given. What are the controls and actions? Working in confined space / Staff/Mngt/Cus tomers Manual Handling Training (see RA) Impact wounds / Trips (use numbers) Items weighing 12kg or above should be tackled by two members of staff Stocking activity ongoing throughout shift with suitable break intervals Stock not left unattended in aisles. Keep fire exits clear at all times free from cages. Sufficient task lighting at all times. 6 2 Controlled Risk Rating Who is at risk? Controlled Likelihood Stocking Shelves What are the risks & potential injuries? Controlled Severity Hazard Frequency The whole team must be told that under no circumstances are they to admit liability in case of any accidents; all incidents or questions involving insurance must be referred to LUSU the next day. 10 80 Who is responsible for the control? LUSU Retail Manager Stock on shop floor Slipping Staff/ Sufficient lighting throughout. Tripping Customers Appropriate foot wear for work. Falling (use numbers) Controlled Risk Rating What are the controls and actions? Controlled Likelihood Who is at risk? Controlled Severity What are the risks & potential injuries? Frequency Hazard Who is responsible for the control? 5 2 7 49 LUSU Retail Manager 5 1 7 42 LUSU Retail Manager 5 1 1 6 LUSU Retail Manager Staff trained in relevant manual handling (see MH training – shelving units) when moving stock through from stockroom and stacking units use sack truck were necessary. Unshelved / moving stock not left in centre of walkways. Ensure all fire exits are left clear. Wet floor signs used where necessary. Stock room floor area Slipping Staff/ Tripping Delivery Staff Keep area free from debris and spillages removed immediately. Appropriate footwear wore at work. Stock stored appropriately on shelving units or designated storage areas. Wet floor signs used where necessary. Sufficient task lighting. Third party users provide RA for tasks carried out in stock area; subject to approval by reviewer. No unauthorised personnel allowed in stock room or kitchen area. Moving of stock to different storage locations Strains Tripping Staff Designated moving equipment (sack truck, large wheeled trolley) should be used – avoiding overloading. 2 people to be involved in moving large/heavy items Route should be assessed prior to task to ensure (use numbers) Controlled Risk Rating What are the controls and actions? Controlled Likelihood Who is at risk? Controlled Severity What are the risks & potential injuries? Frequency Hazard Who is responsible for the control? no risk of obstructions or uneven surfaces. MH techniques should be adhered to when loading. Regular recovery time following task High rise shelving units Crushing Staff Strains Lighter weight products stacked higher up. 5 1 4 24 LUSU Retail Manager 5 2 7 49 LUSU Retail Manager Heavier products stacked towards the bottom. Stock packaging checked prior to stacking for damage; damaged packaging removed and products stored suitably. Maximum weight exceeding Staff trained in steps / ladder use. MH training followed at all times. Waste Disposal Strains Slipping Tripping Falling Staff Waste removed from premises in appropriate containers. A Manual Handling Training (see RA) Sufficient task lighting. Size of load and bulky nature of load reasonable and sensible. Use of PPE, eg gloves to improve grip, handle sharps and reduce risk of injury. Regular recovery time following repetitive actions. Route to bins should be known in advance. Where waste is to be removed to external bins, two people will be involved in the lifting of heavy (use numbers) Controlled Risk Rating What are the controls and actions? Controlled Likelihood Who is at risk? Controlled Severity What are the risks & potential injuries? Frequency Hazard Who is responsible for the control? loads. Out of Date/Perishable Items Food poisoning Customers Mild Stomach Upsets 5 2 2 20 LUSU Retail Manager 5 1 4 24 LUSU Retail Manager 5 2 2 20 LUSU Retail Manager 1 5 1 6 LUSU Retail Manager Health & Safety procedures adhered to, regular temp checks taken and recorded Temp Controlled Foods Light cleaning duties All perishable foods disposed as date expires Regular maintenance contract on display fridges to ensure controlled temps Bruising / allergens / slips Staff / Mngt Manual Handling Training (see RA) Use of PPE and refer to COSHH assessments. Mopping of floors only takes place during closed hours wet floor signs must be displayed Sufficient task lighting All spillages to be mopped up immediately Coffee Machine Burns Staff/ Scalds Customers Cleaning to take place during closed or quiet periods Tasks to be completed according to manufacturer’s instructions Staff trained for cleaning/restocking purposes Mains Power Electrocution Staff Annual electrical safety testing. Mains power units display warning signs and relevant safety information. No accessible or trailing cables. Access to authorised personnel only. All portable appliances to carry dated PAT certification. All fridges are maintained through contract with (use numbers) Controlled Risk Rating What are the controls and actions? Controlled Likelihood Who is at risk? Controlled Severity What are the risks & potential injuries? Frequency Hazard Who is responsible for the control? Allcool Refrigeration Ltd. Bi-annual clean and maintenance visit. Central Moving stock in cages/Deliveries Sprains / Strain / Musculoskeletal injuries / Staff/Mngt/ Customers Fully stocked cages delivered directly onto shop floor by drivers with use of Master Mover (co-op provided) 6 2 7 56 LUSU Retail Manager 5 2 7 49 LUSU Retail Manager Quality and security checked on arrival Manual Handling Training (see RA) Cage moved gently and with fluidity in accordance with training. Sufficient task lighting during movement of cages, full or otherwise. Weight of load should not exceed 500kg Stock in cage not stocked above sight line, where this is unavoidable, two people will be involved in moving the cage. Tiled surface on shop floor clear of all hazards and dry at all times. Newspaper delivery Musculoskeletal injury / trips Staff/ Manual Handling Training (see RA) Mngt Sufficient task lighting. One person involved in the task and bundle size lifted kept to a minimum. Use of mechanical lifting equipment unless stairs (use numbers) Controlled Risk Rating What are the controls and actions? Controlled Likelihood Who is at risk? Controlled Severity What are the risks & potential injuries? Frequency Hazard Who is responsible for the control? are a part of the route. Regular recovery time following repetitive lifting actions. LUSU Shop Deliveries Strains Delivery Staff/ Staff All arriving stock deposited by delivery persons in stock room. 5 1 1 6 LUSU Retail Manager 5 2 1 7 LUSU Retail Manager 5 2 2 20 LUSU Retail Manager Subsequent storage of stock to follow previous assessment. Electric Pastry Oven Burns Staff Electrocution No accessible or trailing cables. Access to authorised personnel only Appliances to carry dated PAT certification. Full training for staff using manufacturer’s instructions Water Dispenser Electrocution Staff/ Slips Customers Contaminated water Annual electrical safety testing. Mains power units display warning signs and relevant safety information. No accessible or trailing cables. Appliance to carry dated PAT certification. Overflow checked regularly to avoid overspills University Legionnaire testing to verify water quality Maintenance contract to cover bi annual cleaning and general maintenance of dispenser Rear Loading Bay Falling Slipping Tripping Staff/ Hazard nosing to steps. Delivery Staff Hazard tape across front of bay (use numbers) Controlled Risk Rating What are the controls and actions? Controlled Likelihood Who is at risk? Controlled Severity What are the risks & potential injuries? Frequency Hazard Who is responsible for the control? 5 2 7 49 LUSU Retail Manager 5 1 7 42 LUSU Retail Manager Removable barrier across loading area (chain barrier). Area kept clear of debris. Designated stacking area for surplus crates. No unauthorised persons allowed. Rear stocking area / Boxed products Crushing Strains Staff Clothes boxes stocked on shelving provided. Alternatively no more than 3 units high. Quality of box packaging checked prior to stacking; unstable boxes removed and alternate storage used. Staff trained in manual handling (see MH training). Sufficient task lighting. Sign Off The undersigned believe this assessment to cover all significant risks associated with the above activity and accept their responsibilities for ensuring associated controls are in place Authorisation Position Print Name Risk Assessor Allison Cooke Sign Date 30/1/14 Person Responsible for Health & Safety in this Area of LUSU Please detail how this risk assessment will be communicated to all parties who must comply: Communication Who needs to understand this assessment? How will this be communicated to them? Staff Briefing meeting Students Briefing meeting Person Responsible Date Risk Rating Guide Below is a simple guide to help risk assessors determine the risk rating of each hazard identified. A Risk Assessment should be ‘Suitable and Sufficient’. That is to say: It should identify the risks arising in connection with the activity. The level of detail included should be proportionate to the risk. It must consider all those who might be affected i.e. staff, students, etc. It should be appropriate to the activity and should identify the period of time for which it is to remain valid. Risk = (Frequency + Severity) X Likelihood FREQUENCY OF EXPOSURE + SEVERITY OF INJURY X LIKELIHOOD OF OCCURRENCE = RISK 1 VERY RARE ANNUALLY OR LESS 1 MINOR INJURY – POSSIBLE FIRST AID ONLY 1 ALMOST IMPOSSIBLE 2 NO ACTION – BUT MONITOR 2 SEVERAL TIMES PER YEAR 2 SEVEN DAY INJURY – RIDDOR 4 REMOTE 50 RISK PERHAPS ACCEPTABLE - MONITOR 3 ONCE A MONTH 3 MAJOR INJURY – REPORTABLE TO RIDDOR 7 UNUSUAL YET POSSIBLE 90 MODERATE RISK – POSSIBLE ACTION 10 QUITE POSSIBLE 120 SUBSTANTIAL RISK – CORRECTION REQUIRED 13 PROBABLE 180 HIGH RISK – TAKE URGENT ACTION VERY LIKELY 247 VERY HIGH RISK – TAKE IMMEDIATE ACTION 4 ONCE A WEEK 4 SEVERE INJURY PERMANENT DISABLITLITY 5 FREQUENT – FEW TIMES A WEEK 5 FATALITY 6 VERY FREQUENT – SEVERAL TIMES A DAY 6 MULTIPLE FATALITIES 7 CONTINOUS/ REPEATEDLY GRADE (L) Low (M) Medium 16 19 CERTAIN (H) High