060715175113Abstract_SaurabhPatankar_SUSCHEME_06-07

advertisement

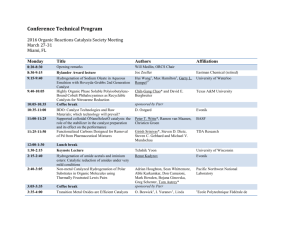

Biobased products: Selective hydrogenation of levulinic acid and γ-valerolactone on copper supported zirconia catalysts to 1,4-pentanediol and 2-methyltetrahydrofuran Saurabh. C Patankar1, Ganapati. D Yadav1*, Flora. T T Ng2 1 Department of Chemical Engineering, Institute of Chemical Technology, Matunga, Mumbai 400019, India 2 Department of Chemical Engineering, University of Waterloo, 200 University Avenue West, Waterloo, ON N2L3G1, Canada Email: scpatankar@gmail.com, gd.yadav@ictmumbai.edu.in, gdyadav@yahoo.com, fttng@uwaterloo.ca Phone: 022-3361-1001 Fax: 022-3362-1002 Introduction One of the aspects in the current strategy to utilize bio based energy is to synthesize platform chemicals from biological source which can then be valorized to compounds used as liquid fuels and intermediate chemicals. Levulinic acid (LA) and γ-valerolactone (GVL) have been developed as platform chemicals [1]. GVL and the derived compounds have properties which are suitable for handling and usage with the existing liquid fuel infrastructure [2]. The synthesis of GVL from LA involves hydrogenation of LA to form hydroxypentanoic acid and dehydration of the acid to form GVL. 1,4-pentanediol (PDO) and 2methyl tetrahydrofuran (MTHF) can be obtained by additional cycles of hydrogenation and dehydration of GVL. Direct vapour phase hydrocyclization of LA to MTHF was reported in which 1,4-dioxane was used as a solvent with nanocomposite copper/silica catalyst [3]. The objective of the current work was to study liquid phase synthesis of PDO and MTHF from LA in a single pot using eco-friendly solvents and Cu/zirconia catalyst. Hence LA hydrogenation and GVL hydrogenation using ethanol as a solvent were studied separately to understand mechanism and kinetics. The results of this study were then used to design a robust catalyst for the single pot synthesis of PDO and MTHF from LA. Materials and Methods Chemicals. Copper (II) nitrate hemipentahydrate [Cu(NO3)2.2.5 H2O], zirconium(IV)oxynitratehydrate [Zr(NO3)2. x H2O], Oxalic acid [C2H2O4], LA [C5H8O3], GVL [C5H8O2], ethanol [C2H6O] were procured from Sigma Aldrich Chemical Co. Canada. All the chemicals were of AR grade and used as received. Catalyst Synthesis. Required amount of copper (II) nitrate hemipentahydrate and zirconium(IV) oxynitrate hydrate were mixed in ethanol such that the concentration of the nitrate solution was 0.1M. 20% Molar excess of oxalic acid ethanolic solution was added rapidly to the nitrate solution. This resulted in the precipitation of copper oxalate and zirconyl oxalate. The slurry was stirred for 30 min 1 and the precipitate was separated by centrifugation. The precipitate was then calcined at 673 K for 3 h in air. The material obtained was used as the catalyst. Reaction setup and analysis. All experiments for hydrogenation of LA and hydrogenation of GVL were carried out in a 300 cm3 Parr autoclave provided with 45° pitched bladed turbine impeller ,and temperature and pressure controllers. The reaction mixture consisted of known quantities of LA or GVL dissolved in ethanol; the catalyst and n-decane as internal standard. The reactor was purged with nitrogen to remove traces of air and pressurized with hydrogen. The reactor was then heated to desired temperature. During the reaction, periodic samples were withdrawn and analyzed on GC (Agilent 7980A). A HP-INNOwax column and flame ionization detector were used. The formation of products was confirmed by matching the residence time of pure samples. Results and Discussion The synthesized catalyst was thoroughly characterized using TPD-NH3, TPD-CO2, TPR, XRD, and BET analysis (Table 2); per se and after reuse to understand the nature of active sites and their role in catalyzing the reaction. It was ensured that the reactions of LA hydrogenation and GVL hydrogenation were intrinsically kinetically controlled. Mathematical models were developed and validated to predict the rate of LA hydrogenation and GVL hydrogenation. Table 1: Surface area and pore size of fresh and used copper supported on zirconia catalyst Catalyst: Cu/ZrO2 Surface area (m2/g) Pore size (nm) Pore volume (cm3/g) Fresh 74 12.2 0.25 Reuse 1 69 12.6 0.24 Reuse 2 64 13.4 0.19 The activation energies were calculated from the reaction rate constant values at different temperatures for both LA and GVL hydrogenation reactions. The activation energy for LA hydrogenation was found to be 18.0 kcal/mol and 25.8 kcal/mol for GVL hydrogenation (Fig. 1 and Fig. 2). The reactions give 100% conversion after 6 h for reactions done at 473K. In case of levulinic acid hydrogenation, γvalerolactone was formed with 70% selectivity and ethyl levulinate was 30%. In the case of γvalerolactone hydrogenation, 1,4-pentanediol was formed with ln k4 methyltetrahydrofuran was 50%. 0 y = -13008x + 23.778 -2 R² = 0.9911 -4 -6 -8 0.0021 0.0022 0.0023 -1 1/T (K ) 2 0.0024 50% selectivity and 2- Figure 1: Arrhenius plot for LA hydrogenation reaction 0 ln k1 -2 -4 y = -9059.6x + 15.146 R² = 0.9866 -6 -8 0.0021 0.0022 0.0023 1/T (K-1) 0.0024 Figure 2: Arrhenius plot for GVL hydrogenation reaction Conclusion The GVL hydrogenation involves the breaking of the C-O bond in the furan ring and hence has higher activation energy than LA hydrogenation. It was observed that the values of adsorption constants of hydrogen on metal sites in LA hydrogenation and of GVL and hydrogen on metal sites in GVL hydrogenation were high. Thus the temperature is the critical aspect for the efficacy of the catalyst. As the temperature increases, the value of adsorption constant decreases and rate of reaction increases. In order to develop a cascade engineered process for synthesis of PDO and MTHF directly from LA, the process must operate at a high temperature ~473 K and at a higher pressure ~ 60 atm so that the reactants and products are in liquid phase. The catalyst for the cascade engineered synthesis must have metal and acid sites with higher pore size ~ 12nm or greater to eliminate the diffusion resistance. The catalyst also needs to be robust so that it doesn’t get deactivated due to multiple sequential steps. References [1]J. Bozell, L. Moens, D. Elliot, Y. Wang, S. Fitzpatrick, Res. Conserv. Recycl. 2000, 8, 227 [2] I. Horvath, H. Mehdi, V. Fabos, L. Boda, L. T. Mika, Green Chem. 2008, 10, 238 [10] P. Upare, J. M. Lee, Y. Hwang, D. Hwang, J. H. Lee, S. Halligudi, J. S. Hwang, J. S. Chang, ChemSusChem. 2011, 4, 1749 3