samples deformation

advertisement

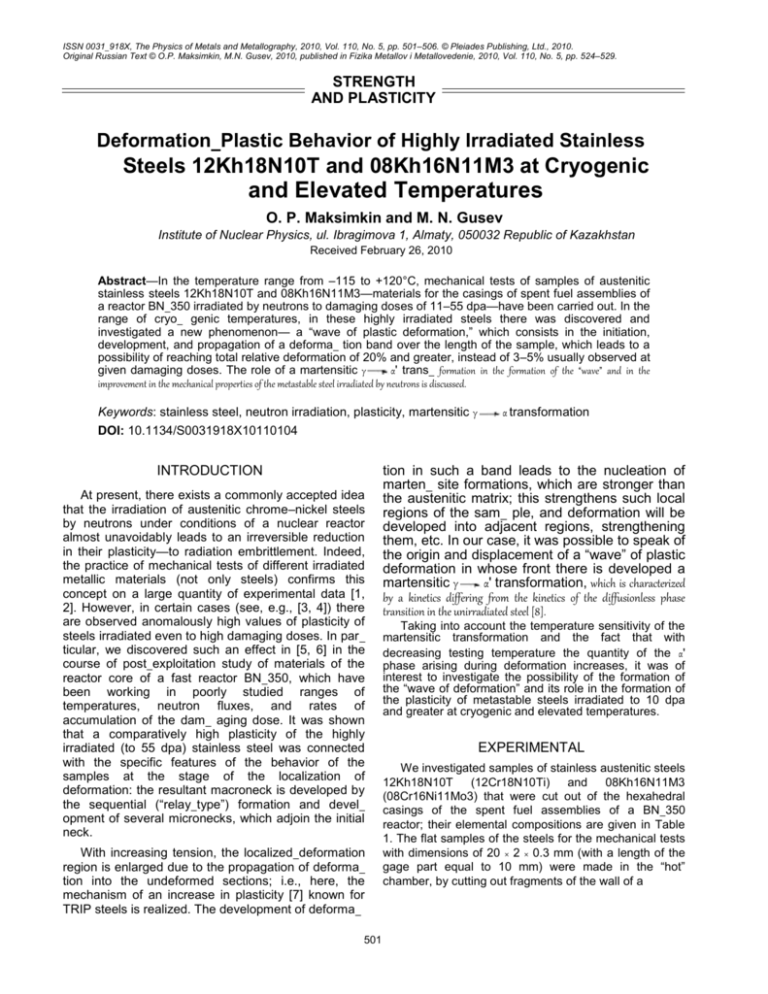

ISSN 0031_918X, The Physics of Metals and Metallography, 2010, Vol. 110, No. 5, pp. 501–506. © Pleiades Publishing, Ltd., 2010. Original Russian Text © O.P. Maksimkin, M.N. Gusev, 2010, published in Fizika Metallov i Metallovedenie, 2010, Vol. 110, No. 5, pp. 524–529. STRENGTH AND PLASTICITY Deformation_Plastic Behavior of Highly Irradiated Stainless Steels 12Kh18N10T and 08Kh16N11M3 at Cryogenic and Elevated Temperatures O. P. Maksimkin and M. N. Gusev Institute of Nuclear Physics, ul. Ibragimova 1, Almaty, 050032 Republic of Kazakhstan Received February 26, 2010 Abstract—In the temperature range from –115 to +120°C, mechanical tests of samples of austenitic stainless steels 12Kh18N10T and 08Kh16N11M3—materials for the casings of spent fuel assemblies of a reactor BN_350 irradiated by neutrons to damaging doses of 11–55 dpa—have been carried out. In the range of cryo_ genic temperatures, in these highly irradiated steels there was discovered and investigated a new phenomenon— a “wave of plastic deformation,” which consists in the initiation, development, and propagation of a deforma_ tion band over the length of the sample, which leads to a possibility of reaching total relative deformation of 20% and greater, instead of 3–5% usually observed at given damaging doses. The role of a martensitic γ α' trans_ formation in the formation of the “wave” and in the improvement in the mechanical properties of the metastable steel irradiated by neutrons is discussed. Keywords: stainless steel, neutron irradiation, plasticity, martensitic γ DOI: 10.1134/S0031918X10110104 INTRODUCTION At present, there exists a commonly accepted idea that the irradiation of austenitic chrome–nickel steels by neutrons under conditions of a nuclear reactor almost unavoidably leads to an irreversible reduction in their plasticity—to radiation embrittlement. Indeed, the practice of mechanical tests of different irradiated metallic materials (not only steels) confirms this concept on a large quantity of experimental data [1, 2]. However, in certain cases (see, e.g., [3, 4]) there are observed anomalously high values of plasticity of steels irradiated even to high damaging doses. In par_ ticular, we discovered such an effect in [5, 6] in the course of post_exploitation study of materials of the reactor core of a fast reactor BN_350, which have been working in poorly studied ranges of temperatures, neutron fluxes, and rates of accumulation of the dam_ aging dose. It was shown that a comparatively high plasticity of the highly irradiated (to 55 dpa) stainless steel was connected with the specific features of the behavior of the samples at the stage of the localization of deformation: the resultant macroneck is developed by the sequential (“relay_type”) formation and devel_ opment of several micronecks, which adjoin the initial neck. With increasing tension, the localized_deformation region is enlarged due to the propagation of deforma_ tion into the undeformed sections; i.e., here, the mechanism of an increase in plasticity [7] known for TRIP steels is realized. The development of deforma_ 501 α transformation tion in such a band leads to the nucleation of marten_ site formations, which are stronger than the austenitic matrix; this strengthens such local regions of the sam_ ple, and deformation will be developed into adjacent regions, strengthening them, etc. In our case, it was possible to speak of the origin and displacement of a “wave” of plastic deformation in whose front there is developed a martensitic γ α' transformation, which is characterized by a kinetics differing from the kinetics of the diffusionless phase transition in the unirradiated steel [8]. Taking into account the temperature sensitivity of the martensitic transformation and the fact that with decreasing testing temperature the quantity of the α' phase arising during deformation increases, it was of interest to investigate the possibility of the formation of the “wave of deformation” and its role in the formation of the plasticity of metastable steels irradiated to 10 dpa and greater at cryogenic and elevated temperatures. EXPERIMENTAL We investigated samples of stainless austenitic steels 12Kh18N10T (12Cr18N10Ti) and 08Kh16N11M3 (08Cr16Ni11Mo3) that were cut out of the hexahedral casings of the spent fuel assemblies of a BN_350 reactor; their elemental compositions are given in Table 1. The flat samples of the steels for the mechanical tests with dimensions of 20 × 2 × 0.3 mm (with a length of the gage part equal to 10 mm) were made in the “hot” chamber, by cutting out fragments of the wall of a 502 MAKSIMKIN, GUSEV Table 1. Chemical composition of stainless steels under investigation (wt %) Element Steel C 08Kh16N11M3 12Kh18N10T Ni 0.08 11–12 0.12 10.7 Cr Mn 15–17 17.0 1–2 1.7 Mo Ti Si – 0.5 2.5–3 – 0.5–1 0.34 B 0.005 – S P Fe 0.02 0.01 0.01 0.03 For balance For balance Table 2. Parameters of the irradiation of the investigated samples of steels 12Kh18N10T and 08Kh16N11M3 Assembly Steel Mark (distance from the center of the core), mm Irradiation temperature, °C Damaging dose, dpa –300 290 13.2 TsTs_19 '' +500 423 26 TsTs_19 '' –160 330 55 N_214(1) '' 0 337 17 –500 302 11 12 N_42 12Kh18N10T V_300 08Kh16N11M3 V_337 '' –500 305 N_214(2) '' –900 281 ,σ MPa hexahedral casing from different “marks”—sites located at different distances from the center of the core. In a number of cases, samples with a length of the gage part of 6–7 mm were also used. The parameters of the irradiation of the samples investigated are given in Table 2. Before the irradiation, the steels were sub_ jected to a thermomechanical treatment, which con_ sisted in cold deformation to 15–20% with a subse_ quent annealing at 800°С for 1 h. 1100 1000 900 800 700 600 500 400 300 200 100 0 1 3 4 2 1.27 The mechanical tests of the irradiated and unirra_ diated samples (for the uniaxial tension) at a strain rate of V = 8.4 × 10–4 s–1 (0.5 mm/min) were carried out on an Instron_1195 machine additionally equipped with pneumatic grips and a temperature chamber, which makes it possible to carry out experiments in the range of temperatures from –120 to +300°С. For studying the specific features of the deformation_plastic behav_ ior of the highly irradiated steel, the method of “digital marker extensometry” was employed [9]. The use of this method, which includes a digital filming of a min_ iature continuously deformed irradiated sample, makes it possible to trace the development of the local_ ized deformation and to calculate true_stress–true_ strain dependences. After the termination of tension, the content of the magnetic α' phase was measured in the sample with the aid of a ferroprobe and the distribution of this phase along the working length was analyzed. ini RESULTS AND DISCUSSION 10 20 30 40 ε, % 50 60 Fig. 1. Engineering diagrams for the unirradiated and irra_ diated samples of steels 12Kh18N10T and 08Kh16N11M3: (ini) unirradiated steel 12Kh18N10T after austenitizing (1050°С); (1) steel 08Kh16N11M3, V_337 (mark, “–500”; dose, 12 dpa); (2) steel 08Kh16N11M3, N_214(2) (mark, “–900”; dose, 1.27 dpa); (3) steel 12Kh18N10T, TsTs_19 (mark, “–160”; dose, 55 dpa); (4) steel 12Kh18N10T, TsTs_19 (mark, “+500”; dose, 26 dpa). Phenomenon of the “Wave of Deformation” in Highly Irradiated Steels Figure 1 displays engineering diagrams obtained in uniaxial tensile tests of the unirradiated and irradiated samples. As follows from the figure, the unirradiated stainless steel is characterized by a comparatively high plasticity and a significant capability for strain harden_ ing: its ultimate strength 2.5–3 times exceeds the yield stress. Upon irradiation, the yield stress grows with increasing damaging dose, and the plasticity is THE PHYSICS OF METALS AND METALLOGRAPHY Vol. 110 No. 5 2010 DEFORMATION_PLASTIC BEHAVIOR 503 σ, dσ/dε 2.200 5 2.000 1.800 4 1.600 1 . 4 0 0 1 . 2 0 0 1 1 2 3 4 5 6 7 Fig. 2. Films taken during the deformation of the sample of steel 12Kh18N10T irradiated to 55 dpa (TsTs_19, “ 160 mm”). White rounded elements, markers (drop_ lets of a coloring substance), which facilitate the analysis of images and conducting calculations [9]. Arrows near photos 5–7 note the second (immobile) neck near one of the grips. The images were subjected to a digital processing for increasing contrast. 2 1.000 800 3 600 400 200 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 ε Fig. 3. True_stress–true_strain (σ–ε) diagrams for reduced, being approximately 3–7% at 5–15 dpa [10]. This fact is illustrated by curves 1 and 2 in Fig. 1. It is also seen from the figure that the highly irradiated (to 12 dpa) steels 12Kh18N10T and 08Kh16N11M3 have low plasticity; deformation occurs locally and, according to the data of videofilming, almost immedi_ ately after the yield stress is reached, there is developed a neck [9, 10]. This result agrees with the data of other authors, who investigated the effects of radiation on analogous steels [11]. Taking into account these data, we expected that the plasticity for steel 12Kh18N10T irradiated to doses 26–55 dpa will be no more than a few percent and that in the highly irradiated sample a region of localized deformation (neck) will be formed immediately after the yield stress is reached. However, the experiments showed a considerably larger plastic_ steel 12Kh18N10T irradiated to (1) 55 dpa, (2) 26 dpa and (3) unirradiated. The dσ/dε [MPa]–ε [rel. units] curves for the samples irradiated to (4) 55 dpa and (5) 26 dpa are also shown. It is obvious that to “decelerate” the development of a neck and to prevent the premature fracture or, as a minimum, the translation of deformation into an adjacent, undeformed volume, it is necessary that the law of strain hardening be changed, i.e., that after a certain degree of deformation the relationship (1) would cease to be fulfilled. For the unirradiated metals and pure metals irradiated by neutrons, this, as a rule, does not occur; the value of dσ/dε diminishes with increasing ε and the material fails rapidly. To increase plasticity, it is necessary that a certain process occurr, which can change the structural_phase state of ity: to 20% and more, and the engineering diagrams the material and would ensure additional local (Fig. 1, curves 3, 4) had long yield plateaus. strengthen_ An analysis of the photographs that were made ing. Such a process in stainless metastable steel is a sequentially in the course of experiment (Fig. 2) deformation_induced martensitic γ α transforma_ showed that in the steel sample irradiated to high dam_ tion, where the resultant α' phase is somewhat stronger aging doses (55 dpa) there is observed a “deformation than the γ matrix. wave” (running neck), which, moving along the sam_ Figure 3 displays stress–strain curves obtained ple, passes more than half its gage part. Upon the using the method presented in [9] (the curves are pas_ cal_ sage of the “wave,” the local deformation almost culated in the approximation of a uniaxial state of jumpwise increases (by the value of the “wave stress). Graphs of derivatives dσ/dε, which character_ ampli_ tude”) and after this—outside of the wave—the mate_ ize the intensity of the strain hardening, are also rial practically is not deformed. shown. The condition for the appearance and development It is seen from Fig. 3 that for steel 12Kh18N10T of localized deformation is, as is known, determined by an inequality [12] irradiated to 26 and 55 dpa, almost immediately after the yield point the magnitude of dσ/dε is reduced to dσ/dε ≤ σ. (1) values less than the operating stresses σ, which, taking In accordance with condition (1), the localization into account expression (1), leads to the development of deformation begins when the local strain hardening of a neck. However, at the degree of local deformation does not compensate the “geometric softening,” of ~20–25% in the σ–ε curve there is observed a which occurs as a result of the reduction in the area of break, after which dσ/dε grows and its value soon the sample section upon tension. becomes more than the working stress σ. Note that an THE PHYSICS OF METALS AND METALLOGRAPHY Vol. 110 No. 5 2010 504 MAKSIMKIN, GUSEV Table 3. Mechanical properties of samples of steels 12Kh18N10T and 08Kh16N11M3 deformed at different temperatures Steel, assembly, mark 12Kh18N10T N_42, –300 mm 12Kh18N10T N_214(1), 0 mm 12Kh18N10T TsTs_19, +500 mm 12Kh18N10T TsTs_19, –160 mm 08Kh16N11M3 V_300, –500 mm 08Kh16N11M3 V_300, –500 mm 08Kh16N11M3 V_300, –500 mm 08Kh16N11M3 V_337, –500 mm Dose, dpa 13 Testing tempera_ ture, °C σ , 0.2 MPa σu, MPa ε ð, % Presence of a “deforma_ ε, % tion wave” 20 830 1020 <2 5 –40 1030 1110 ~1 53 20 970 1100 <2 5 No –50 980 1120 23 Yes 60 740 850 40 43 Yes* 20 780 930 18 18.5 Yes 120 940 980 ~1 <4 No 20 960 1070 20 22 Yes 11 20 970 1100 1.6 4 No 11 –40 1200 1270 1.5 12 No 11 –80 1110 1270 1 7 No 12 –115 1130 1370 27 28 17 26 55 2.1 No Yes* Yes* * Samples with two "deformation waves” are observed see Fig. 4. can be called a “macrowave” in stainless chrome– nickel steel irradiated to a high damaging dose. analogous increase in the rate of strain hardening was observed in unirradiated steels of this class in the course of deformation at cryogenic temperatures [12]. Furthermore, a similar phenomenon—local strength_ ening and the formation of a “running neck”—was also noted for the manganese steels such as Hadfield steel and for TRIP steels [7]. It is possible to assume that an increase in strengthening (dσ/dε) reflects an increase in the rate of the γ α' phase transition and leads to a displacement of the deformation zone into the adjacent undeformed volume. Let us emphasize a difference of the “wave of defor_ mation” that is considered in this work for highly irradi_ ated steels, from similar phenomena described earlier. This difference is in the fact that the γ α' transfor_ mation, which takes place in the wave front, in highly irradiated steel is characterized by a high intensity of the formation of the α' phase. This is connected with a developed structure of radiation defects and, in turn, it influences the velocity of the displacement of the wave front. Another important difference is the circumstance that the amplitude of deformation in the “wave” is extremely high—in our case the local deformation reaches 30–35%. For comparison, in the Chernov– Luders bands (waves) the deformation amplitude on the yield plateau during the deformation, for example, of Armco iron is on average no more than 4–6%, and the waves of deformation in the unirradiated polycrys_ tals (see, e.g., [13]) have an amplitude of deformation on the order of a fraction of percent or less. This means that the phenomenon considered in our work Effect of the Temperature of Testing on the “Waves of Plastic Deformation” As is known [14], the occurrence of the γ α' transformation is strongly affected by the testing tem_ perature. The lower the temperature, the greater the amount of α' martensite formed during the deformation in the metastable chrome–nickel steel. The tempera_ ture equal to 100°С is maximum for the unirradiated steel 12Kh18N10T; at higher temperatures, no marten_ sitic transformation occurs during deformation. Taking into account these facts, we performed a series of exper_ iments with irradiated steel samples in the range of tem_ peratures of tensile tests from–115 to +120°С. The data obtained are given in Table 3, from which it is seen that the variation of the damaging dose and temperature of testing qualitatively changes the nature of plastic defor_ mation and the value of plasticity. Thus, for steel 12Kh18N10T irradiated to doses more than 10 dpa, the passage from room temperature of testing to –40 and –50°С led to a sharp increase in the plasticity of the material from a few percent (Fig. 5, curve 1) to 20 and 50% (Fig. 5, curves 2 and 3). The data of the videofilming of the surface of the sam_ ples deformed in a cryogenic chamber make it possible to assert that in this case there appears and propagates along the sample a “wave of deformation” which was absent at 20°С. A single “wave” appears near the grip and passes approximately 2/3 of the sample length. Sometimes (approximately in 20% of cases) after the first wave there arises a second wave, which starts from the second grip. In this case, no undeformed space remains in the sample (see Fig. 4). Taking into account the results of magnetometry and the conclusions of the work [4], we can suppose THE PHYSICS OF METALS AND METALLOGRAPHY Vol. 110 No. 5 2010 DEFORMATION_PLASTIC BEHAVIOR 505 Fig. 4. Diagrams of the displacement of the “wave of deformation” in the case of a single wave (to the left) and a double wave (to the right) in the irradiated samples deformed at cryogenic temperatures (the deformed part is noted by dark gray; the undeformed part, by white. The directions of the wave displacements are indicated by arrows). that the reason for the effect noted is the occurrence of a martensitic γ α' transformation in the deformed steel. Its kinetics and degree of influence on the strain hardening have been studied insufficiently for the highly irradiated material, but nevertheless it is obvi_ ous that they can differ significantly from those observed in the unirradiated or weakly irradiated steel. The results obtained attest to the fact that the low_ temperature stimulation of a “wave of deformation” makes it possible to remove or to considerably decrease the effect of radiation embrittlement. the stimulation of a “wave” is substantially lower (–115°С), 0 ,σ MPa For steel 08Kh16N11M3 (Table 3), the tempera_ ture of 1100 1050 1000 950 900 850 800 750 700 650 600 550 2 1 4 10 20 α' transformation in comparison with 12Kh18N10T. For the samples irradiated to 55 dpa, with increas_ ing testing temperature to above 20°С, the “wave” (and the related high plasticity) still is retained at +60°С, but disappears at +120°С (Fig. 5, curve 4). The total plasticity at 120°С is no more than 4–6%. The fact of the suppression of the “wave of deformation” at temperatures exceeding 100°С, which is close to the Md temperature for steel 12Kh18N10T, can indicate the key role of the martensitic γ α transformation in the development of this phenomenon. As follows from the above results, the “wave of deformation” can be both stimulated (by decreasing the temperature to below 20°С) and suppressed (by increasing the temperature to above 100°С). Let us emphasize that the effect of the “wave of deformation” was observed in steel samples cut out from the walls of casings of five different fuel assemblies, which have been exploited in the reactor BN_350 in different times. Accordingly, it cannot be related to the occa_ sional events caused, for example, by a deviation from the steel_grade composition. As a “successful circum_ stance,” which could favor the manifestation of the effect, the fact can be indicated that the largest dam_ aging dose (~55 dpa) was accumulated in the reactor BN_350 at a relatively low temperature of irradiation (330°C), when the swelling of the material is absent. THE PHYSICS OF METALS AND METALLOGRAPHY 30 40 50 ε, % which is caused by the larger stability of this steel with respect to the γ 3 Fig. 5. Engineering diagrams of deformation for highly irradiated steel 12Kh18N10T: (1) assembly, N_42; “mark, "–300 mm”; 13 dpa; testing at 20°С; (2) N_214(1); mark, “0 mm”; 17 dpa; testing at –50°С; (3) N_42; mark, “ 300 mm”; 13 dpa; testing at –40°С; and (4) TsTs_19; mark, “–160 mm”; 55 dpa; testing at +120°С. CONCLUSIONS The above results of materials_science studies of the stainless steels 12Kh18N10T and 08Kh16N11M3 carried out at the stage of decommissioning of the fast reactor BN_350 indicate that the characteristics of strength and plasticity of the materials exploited in the core after prolonged irradiation (55 dpa) are very sen_ sitive not only to the parameters of irradiation (tem_ perature, damaging dose), but also to the testing tem_ perature. As a rule, an increase in the testing tempera_ ture led to a worsening, and a decrease in temperature, to an improvement in the plastic characteristics of highly irradiated steels. It has been experimentally shown that in this case in the sample there arises and propagates along its gage part a deformation band (or several bands)—a “wave,” in the front of which there occurs a deformation_induced γ α' phase transfor_ mation. Apparently, during the deformation of highly irra_ diated metastable stainless steels under consideration, Vol. 110 No. 5 2010 506 MAKSIMKIN, GUSEV at some damaging doses, temperatures, and tensile strain rates there is achieved an optimum combination of the parameters of the defect structure, rate of nucle_ ation of martensite α' phase at radiation defects, etc., which in total ensures a strengthening level that com_ pensates for the geometric softening in the place of localization of plastic flow. 7. 8. REFERENCES 1. A. M. Parshin, “Structure, Strength and Radiation Damageability of Corrosion_Resistant Steels and Alloys,” (Metallurgiya, Chelyabinsk, 1988) [in Rus_ sian]. 2. V. Barabash, “Materials Challenges for ITER— Cur_ rent Status and Future Activities,” in Abstr. 12th Int. Conf. of Fusion Reactor Materials (Santa_Barbara, 2005). 3. A. N. Lapin, V. A. Nikolaev, and I. A. Razov, “Mechan_ ical Properties of 12Kh18N10T Steel after Neutron Irradiation and Their Recovery upon Annealing,” Fiz. Khim. Obrab. Mater., No. 1, 8–12 (1970). 4. A. M. Pecherin, V. K. Shamardin, Yu. D. Gon_ charenko, and V. A. Krasnoselov, “Formation of Mar_ tensite of Deformation in 07Kh18N9 Steels and Radia_ tion_Stimulated Structure_Phase Transformations,” Vopr. At. Nauki Tekh., Ser.: Fiz. Radiats. Povrezhd. Radiats. Materialoved., No. 5 (47), 36–44 (1988). 5. M. N. Gusev, “A New and Unusual Deformation Behavior Observed in 12Cr18Ni10Ti Stainless Steel Irradiated at 10°C to 55 dpa in BN_350,” in Proc. 13th Int. Conf. on Fusion Reactor Materials (Nice, 2007), pp. 362–368. 6. M. N. Gusev, O. P. Maksimkin, I. S. Osipov, and F. A. Garner, “Anomalously Large Deformation of 9. 10. 11. 12. 13. 12Cr18Ni10Ti Austenitic Steel Irradiated to 55 dpa at 310°C in the BN_350 Reactor,” J. Nuclear Mater 386– 388, 273–276 (2009). I. Ya. Georgieva, “High_Strength Steels with a Marten_ sitic_Transformation_Induced Plasticity,” in Itogi Nauki Tekhniki, ser “Metalloved. Term. Obrab.” (Mos_ cow, 1982), Vol. 16, pp. 69–105 [in Russian]. M. N. Gusev, O. P. Maksimkin, and D. A. Toktogulova, “New Physical Effect in Highly Irradiated Stainless Steels—“Waves of Plastic Deformation”—and Its Practical Use,” Vestnik Nat. Yad. Tsentr Resp. Kazakh_ stan, No. 4, 27–33 (2008). O. P. Maksimkin, M. N. Gusev, and I. S. Osipov, “Method of Study of Localization of Deformation in Metal Materials Irradiated to High Damaging Doses,” Zavod. Lab., Diagn. Mater. 72 (11), 52–55 (2006). M. N. Gusev, O. P. Maksimkin, and I. S. Osipov, “New Results of Materials_Science Studies Using Miniature Samples of Iron, Molybdenum, and Stainless Steels Irradiated by High_Energy Particles,” in 5th Int. Conf. “Nuclear Radiation Physics”, ICNRP_05 (Almaty, 2005), Vol. 2, pp. 359– 367. V. S. Neustroev, “Low_Temperature Radiation Dam_ ageability of Austenitic Steels Irradiated in Research and Power Reactors,” Abstract of the Doctoral Disserta_ tion in Technical Sciences (Moscow, 2006). T. S. Byun, “Plastic Instability Behavior of BCC and HCP Metals after Low Temperature Neutron Irradia_ tion,” J. Nucl. Mater. 329–333, 998–1002 (2004). T. M. Poletika, “Localization of Deformation in Zirco_ nium_Based Alloys,” Materialovedenie, No. 10, 32–36 (1999). 14. V. V. Sagaradze and A. I. Uvarov, Strengthening of Aus_ tenitic Steels (Nauka, Moscow, 1989) [in Russian]. THE PHYSICS OF METALS AND METALLOGRAPHY Vol. 110 No. 5 2010