Sample Biological Material Standard Operating Procedure

advertisement

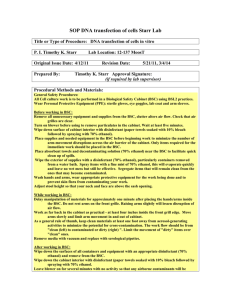

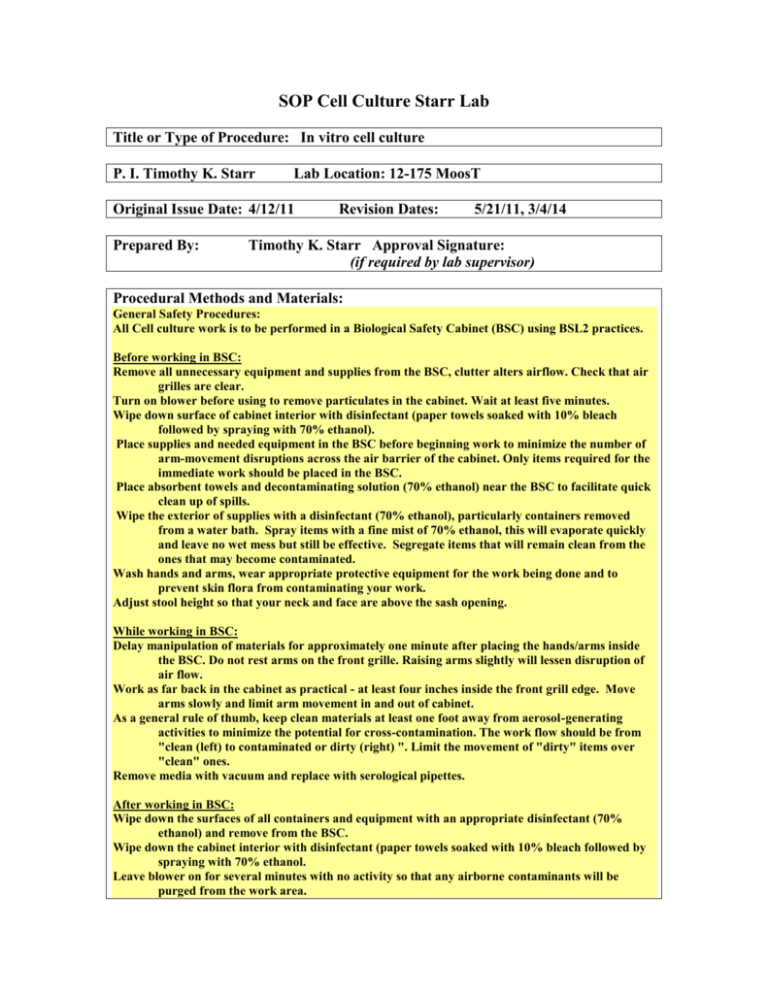

SOP Cell Culture Starr Lab Title or Type of Procedure: In vitro cell culture P. I. Timothy K. Starr Lab Location: 12-175 MoosT Original Issue Date: 4/12/11 Prepared By: Revision Dates: 5/21/11, 3/4/14 Timothy K. Starr Approval Signature: (if required by lab supervisor) Procedural Methods and Materials: General Safety Procedures: All Cell culture work is to be performed in a Biological Safety Cabinet (BSC) using BSL2 practices. Before working in BSC: Remove all unnecessary equipment and supplies from the BSC, clutter alters airflow. Check that air grilles are clear. Turn on blower before using to remove particulates in the cabinet. Wait at least five minutes. Wipe down surface of cabinet interior with disinfectant (paper towels soaked with 10% bleach followed by spraying with 70% ethanol). Place supplies and needed equipment in the BSC before beginning work to minimize the number of arm-movement disruptions across the air barrier of the cabinet. Only items required for the immediate work should be placed in the BSC. Place absorbent towels and decontaminating solution (70% ethanol) near the BSC to facilitate quick clean up of spills. Wipe the exterior of supplies with a disinfectant (70% ethanol), particularly containers removed from a water bath. Spray items with a fine mist of 70% ethanol, this will evaporate quickly and leave no wet mess but still be effective. Segregate items that will remain clean from the ones that may become contaminated. Wash hands and arms, wear appropriate protective equipment for the work being done and to prevent skin flora from contaminating your work. Adjust stool height so that your neck and face are above the sash opening. While working in BSC: Delay manipulation of materials for approximately one minute after placing the hands/arms inside the BSC. Do not rest arms on the front grille. Raising arms slightly will lessen disruption of air flow. Work as far back in the cabinet as practical - at least four inches inside the front grill edge. Move arms slowly and limit arm movement in and out of cabinet. As a general rule of thumb, keep clean materials at least one foot away from aerosol-generating activities to minimize the potential for cross-contamination. The work flow should be from "clean (left) to contaminated or dirty (right) ". Limit the movement of "dirty" items over "clean" ones. Remove media with vacuum and replace with serological pipettes. After working in BSC: Wipe down the surfaces of all containers and equipment with an appropriate disinfectant (70% ethanol) and remove from the BSC. Wipe down the cabinet interior with disinfectant (paper towels soaked with 10% bleach followed by spraying with 70% ethanol. Leave blower on for several minutes with no activity so that any airborne contaminants will be purged from the work area. Remove gloves and dispose in Biological Hazards bag and wash hands. Tips to prevent contamination: Clean water baths frequently and/or treat water in bath. Clean the inside of incubators frequently, particularly the water tray. Use treated di water in the bottom of the incubator or water tray. Use HEPA filters on incubator CO2 and air intake lines. Replace regularly. Lab coat sleeves can introduce contaminants to biological safety cabinets and incubators. Use coats designated for working in the biological safety cabinet or tissue culture area, launder frequently. Use disposable sleeve guards if contamination has been a problem. Never pour media, remove with vacuum and replace with disposable pipettes. Do not leave flasks of waste media in cabinet, clean after every use. On a regular basis, decontaminate under the air grilles and wherever parts are removable. Media is commonly splattered on the front grille allowing fungus to grow undetected on the under surface of the grille. Decontaminate the surface of carts or trays used to transfer culture flasks between the incubator and the biological safety cabinet or microscope. Keep pipette aids cleaned, especially the nosepiece, and replace filters regularly. Clean and disinfect vacuum tubing. This should be done by sucking up the disinfectant we place in the bottom of the waste flask after we have emptied it and reattached it. Keep the water in the incubator's water jacket full. If water levels in the jacket drop, the ceiling of the incubator will be cooler causing condensate to form. Water then drops onto shelves and cell culture containers. Check port plugs and septums for contamination in incubator interior; they may trap moisture and harbor fungi. Standard Media (NIH3T3, HEK293T/17, HeLa, anything else unless otherwise noted) 500 ml DMEM 50 ml FBS + 5 ml 1x Pen/Strep Freezing cells viably: Freezing media (depends on cell type) Standard: 90% DMEM + 10% DMSO Delicate: 40% growing media, 50% FBS, 10% DMSO 1) Spin cells down and resuspend in freezing media at 1.5e6 cells/ml 2) Aliquot ~ 1.5 ml into freezing vials and place in isopropanol chambers at -80º C overnight. 3) Transfer tubes to cell tank and record in cell tank. Thawing frozen cells 1) Place frozen vial of cells in 37ºC water bath for ~1 minute until cells are almost completely thawed 2) Transfer vial contents to a 15 ml conical tube containing 9 mls pre-warmed media 3) Centrifuge 5 min 1,500 rpm to pellet cells. Discard supernatant 4) Resuspend cell pellet in 10 mls of media and transfer to dish or flask. 5) Place cells in incubator (generally 37ºC with 5% CO2). Passaging (splitting) cells Adherent cells: 1) Aspirate media from cells 2) Place 1 ml Trypsin/EDTA on cells and distribute evenly 3) Incubate 37ºC for 10 min. 4) Add 9 ml media to dish using a serological pipette and mix cells 5) Transfer 1 ml of cell solution to a new plate containing 9 mls of media (effectively splitting cells 1:10) 6) Place cells in incubator Hazard Identification and Risk of Exposure to the Hazards: Sharps Possible exposure to bloodborne pathogens Possible exposure to viral vectors expressing oncogenes and proto-oncogenes (Note: this is especially hazardous for immunosupressed or pregnant laboratory staff) Exposure Controls Specific to Above Risk of Exposure: PPE - Lab coats, safety goggles, mask, gloves, sleeves and sharps containers. Biologic Safety Cabinet during all cell culture work Secondary containment during centrifugation with metal buckets and during transport All sharps and glass waste will be disposed of in an approved hard plastic sharps container (U Stores # CX40245, MS07407 or similar), No Cardboard sharps pouches. Waste Generated and Disposal Methods: Liquid waste will be collected in a flask or beaker containing bleach 10% (v/v) and will soak for 30 minutes before being sewered. Solid waste (petri dishes, pipette tips, other disposables) will be disposed of in a Biohazards bag and incinerated. Sharps containers will be sealed when ¾ full and placed in designated waste area. Refer to the Biological Waste Disposal procedures posted on the Tissue Culture room door for more information Spill Response Procedures: For spill, splash or aerosol clean up: Use paper towels to cover then gently and carefully soak them with 1/10 total volume with appropriate decontaminating agent. When decomintaminating is finished carefully place any and all materials in appropriate bio hazard bin/bag or autoclave bag Refer to the Biological Decontamination and Spill Clean-up Plan posted on the Tissue culture room door for more information Accident Response Procedures: If Incident Results in a Hazard Exposure ( i.e. face or eye splash, cut or puncture with sharps, contact with non-intact skin): • Encourage needle sticks and cuts to bleed, gently wash with soap and water for 5 minutes; flush splashes to the nose, mouth, or skin with water; and flush eyes at the nearest eyewash station with clean water for 15 minutes. • Call 911 or seek medical attention. - For urgent care employees may go to HealthPartners Occupational and Environmental Medicine (M/F day time or Urgent Care after hours), or UMMCFairview Hospital (24 hrs). You may seek medical attention at the closest available medical facility or your own healthcare provider. - Follow-up must be done by HealthPartners Occupational and Environmental Medicine. • Report the incident to your supervisor as soon as possible, fill out the appropriate documentation. - Employee First Report of Injury - Supervisor Incident Investigation Report • Send Incident Report Form to the IBC if exposure has occurred during work on an IBC protocol. • Report all biohazard exposures to the Office of Occupational Health and Safety (612626-5008) or uohs@umn.edu. Note: It is important to fill out all of the appropriate documents to be eligible to collect workers compensation should any complications from the hazardous exposure arise in the future. Notes: References: For further information view the UMN DEHS website containing Bio Basic Fact Sheets at http://www.dehs.umn.edu/bio_basicfacts.htm. For general information on Biosafety, access the Biosafety in Microbiological and Biomedical Laboratories (BMBL) 5th Edition from the CDC at BMBL http://www.cdc.gov/biosafety/publications/bmbl5/index.htm For Material Safety Data Sheets access the Public Health agency of Canada website MSDS http://www.phac-aspc.gc.ca/lab-bio/res/psds-ftss/index-eng.php.