SHWPCE - Homework 7

advertisement

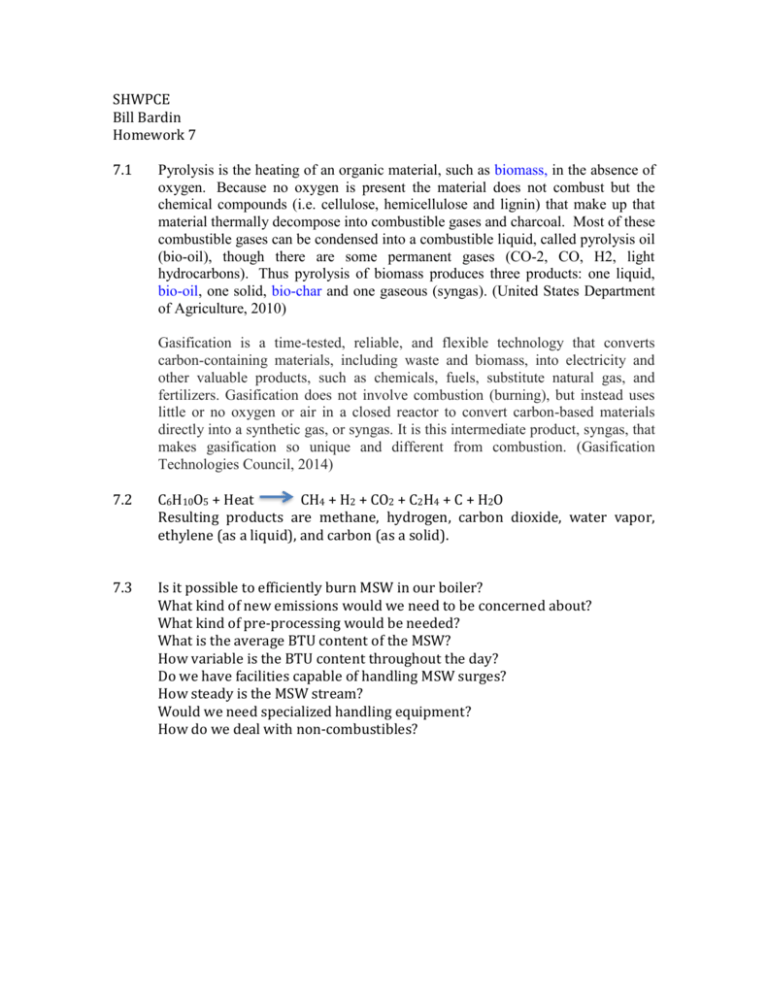

SHWPCE Bill Bardin Homework 7 7.1 Pyrolysis is the heating of an organic material, such as biomass, in the absence of oxygen. Because no oxygen is present the material does not combust but the chemical compounds (i.e. cellulose, hemicellulose and lignin) that make up that material thermally decompose into combustible gases and charcoal. Most of these combustible gases can be condensed into a combustible liquid, called pyrolysis oil (bio-oil), though there are some permanent gases (CO-2, CO, H2, light hydrocarbons). Thus pyrolysis of biomass produces three products: one liquid, bio-oil, one solid, bio-char and one gaseous (syngas). (United States Department of Agriculture, 2010) Gasification is a time-tested, reliable, and flexible technology that converts carbon-containing materials, including waste and biomass, into electricity and other valuable products, such as chemicals, fuels, substitute natural gas, and fertilizers. Gasification does not involve combustion (burning), but instead uses little or no oxygen or air in a closed reactor to convert carbon-based materials directly into a synthetic gas, or syngas. It is this intermediate product, syngas, that makes gasification so unique and different from combustion. (Gasification Technologies Council, 2014) 7.2 C6H10O5 + Heat CH4 + H2 + CO2 + C2H4 + C + H2O Resulting products are methane, hydrogen, carbon dioxide, water vapor, ethylene (as a liquid), and carbon (as a solid). 7.3 Is it possible to efficiently burn MSW in our boiler? What kind of new emissions would we need to be concerned about? What kind of pre-processing would be needed? What is the average BTU content of the MSW? How variable is the BTU content throughout the day? Do we have facilities capable of handling MSW surges? How steady is the MSW stream? Would we need specialized handling equipment? How do we deal with non-combustibles? 7.5 Raw MSW (RDF1) FIne Shred Organic MSW (RDF-4) Organic Seperation Shredding (RDF2) Organic Portion of Shredded MSW (RDF-3) 7.6 MSW is transported to the waste-to-energy plant where it is dumped into storage pits. The waste is typically sorted then further processed by shredding and classification to produce refuse derived fuel (RDF). The RDF is burned to heat water to produce steam which is used to drive a turbine which in turn drives a generator to produce electricity. In some cases, excess steam is used by local companies for process heat. The products of combustion are scrubbed or otherwise extracted form the stack, treated (if needed) and disposed of. 7.7 The burning of tires results in significant amounts of soot, particulate matter, and other air pollutants. Because tires contain much more than just rubber, there are issues with steel cord, and processing additives that also produce toxins. 7.8 Notify the authorities. Take steps to ensure the safety of the protesters. Involve state DEP and other applicable entities. Assemble public data showing the proper operation of the facility. Provide a single point of contact for all press inquiries. Prepare and issue press statements. 7.9 Polyethylene does produce toxic gasses when burned but the plant would have proper pollution control equipment to deal with it. It should also be pointed out that during the screening process, these plastics are culled from the waste stream and recycled rather than be incinerated. 7.10 The EPA has implemented Maximum Achievable Control Technology (MACT) to deal with emissions including dioxins. Dioxin emissions from Municipal Waste Combustors in 1987 totaled 18 pounds, they are expected to be down to ½ ounce in 2014. 7.13 The substance to be tested is placed in the calorimeter The “bomb” is placed in the calorimeter water bath. Electrical ignition wires are placed in the sample Pure oxygen is injected into the calorimeter under pressure. An electrical current is applied to the sample, igniting it. The heat from the combustion heats the water. The temperature profile is recorded over time. The heat energy is calculated form the data. 7.14 The lower heating value (also known as net calorific value) of a fuel is defined as the amount of heat released by combusting a specified quantity (initially at 25°C) and returning the temperature of the combustion products to 150°C, which assumes the latent heat of vaporization of water in the reaction products is not recovered. The LHV are the useful calorific values in boiler combustion plants and are frequently used in Europe. The higher heating value (also known as gross calorific value or gross energy) of a fuel is defined as the amount of heat released by a specified quantity (initially at 25°C) once it is combusted and the products have returned to a temperature of 25°C, which takes into account the latent heat of vaporization of water in the combustion products. The HHV are derived only under laboratory conditions, and are frequently used in the US for solid fuels. 7.16 In a mass-burn unit since there is no classification of the waste there needs to be excess air to insure complete combustion. In an RDF unit, less air is required since the feed stream has been reduced to a more uniform feed supply. 7.17 Bridgeport Resco is a Mass-Burn unit.