Design of Nano-scale Tunnel Diode with High Peak-to

advertisement

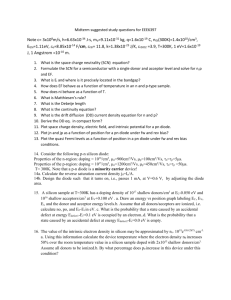

Design of Nano-scale Tunnel Diode with High Peak-to-Valley Current Ratio (PVCR) Gaurav Patel1, Vimal Kumar Mishra2, R.K. Chauhan3 Department of Electronics and Communication Engineering Madan Mohan Malaviya University of Technology, Gorakhpur UP India 273010 dgauravm@gmail.com1, vimal.mishra34@gmail.com2, rkchauhan27@yahoo.com3 Abstract: A nano-scale resonant interband tunnel diode with high peak-to-valley current ratio is proposed. The device shows negative differential resistance with peak to valley current ratio of 3.735. The peak current density is 43.7mA/µm2 and the valley current density is 11.7mA/µm2 at room temperature. The tunnel diode shows very low negative biasing current of 0.376nA, which is almost constant in reverse biasing. This paper also includes study of peak to valley current ratio of the RITD model at different doping profiles. Index Terms— Peak to valley current ratio (PVCR), negative differential resistance (NDR), resonant interband tunnel diode (RITD), CMOS, HBT. Introduction: Rapid development in the fields of computer and communications led to the need for large memory units and very fast processors. The continuing miniaturization of the conventional CMOS technology faces increasing technological difficulties. These difficulties, such as quantum effect problem, will force the miniaturization process to reach its limit. Therefore we need alternative technologies that can provide the required large memories and fast processors. Technologies that contain RITD devices can offer a good alternative technology for high speed applications. RITD has many advantages that make it a promising device. Its operation depends on tunneling process [1] which is a very fast process, so it is a suitable device for ultra high speed applications [2]-[3]. Also RITD can be integrated with CMOS, HFET, and HBT technologies. Its Negative Differential Resistance (NDR) property makes a remarkable reduction in logic circuits' complexity. Since the initial proposal and fabrication of resonant interband tunneling diodes (RITDs), extensive efforts have been made to improve the current-voltage (I-V) characteristics of these devices. Much of this effort has been focused on improving the peak-tovalley current ratios of these structures, and significant progress has been made. It has been shown that once a satisfactory peak-to-valley ratio has been achieved, further improvements in device performance must come from lowering the device capacitance and increasing the peak current density of the device. The performance of semiconductor devices depends on their physical properties, chemical composition as well as on the arrangements of atoms in the crystal [4-5]. Inspite of these properties, the semiconductor nanostructures possess the features of a highly ordered structure within extremely confined geometries [6-7]. Nano-scale diodes exhibit a wide variety of applications in electronic and communication systems, such as in sensors, low power and other optical applications. Besides the synthesis of these devices, the study of electrical transport properties is another important parameter for characterizing nano-devices for potential applications in the area of electronics. Moreover, the electrical properties of the diodes can be controlled by selective doping [8]. The most efficient design of nano p-n junction is a core-shell structure, where the injection occurs uniformly over the entire cross section of the device. I-V characterization of nano-electronic devices requires low level current measurements in the range of nano-amperes to femto-amperes [9-11]. Thus, high sensitive instruments are required, and appropriate measurement and connection techniques must be employed to avoid errors. In recent times, resonant tunneling diode is considered as an element of a future low power, high density integrated circuit because of a possible ultra low power operation with a few electrons [12]. For the practical application, it is necessary for RITD to be operated at room temperature. For this purpose the dimensions of the device must be as small as possible. Therefore, we propose very small size resonant interband tunnel diode model with high peak to valley ratios using Visual TCAD Lab (Cogenda). Results and Discussion The device is a simple hetrojuction architecture of SiGe material. This is a 2-Dimensional model formed on the Visual TCADLAB. Firstly an intrinsic Si substrate of 1nmx1nm (length×width) is taken and n type doping is done on Si substrate, above this 1nm×1nm intrinsic Ge substrate is placed and two contact points are made by attaching(placing) 1nm×1nm Al at both the ends (Anode and Cathode). The device is shielded by 0.5nm layer of HFO2, which reduces the leakage current of the RITD. 4 PVCR 3.5 3 2.5 2 1.5 1 0.5 doping concentartion 0 0 1 2 3 4 5 6 7 8 9 10 Figure 2 Peak to Valley ratio versus donor doping concentration (1018/cm3) inside Si with intrinsic Ge. Figure 1 Schematic diagram of the Si/Ge Tunnel Diode The doping concentration of donor atom inside the Si is varied from the 1x1018 to 1x1019 and various peak-to-valley current ratio is obtained at different doping concentration as shown in the Table1 and Figure 2. No tunnelling current and peak to valley ratio is observed at donor concentration 1x10 18/cm3 to 2x1018/cm3. The tunnelling current observed at 3x1018 doping concentration and there is no current is observed below this doping concentration. The peakto-valley ratio of 3.66 with peak current 39.7 µA and valley current of 10.8 µA and is constant over the doping concentration 3x1018 to 4 x1018/cm3. Different PVCR, peak current and valley current obtained at different doping concentration is shown in Table 1 and graph is shown in Figure 2. Doping Concentration (1018/cm3) 1 Peak Current (µA) 0 Valley Current (µA) - 2 0 - 0 3 39.7 10.8 3.66 4 39.7 10.8 3.66 5 33.0 11.3 2.92 6 37.8 11.4 3.28 7 42.1 11.6 3.62 8 27.2 11.7 2.34 9 27.3 11.8 2.31 10 28.5 12.0 2.37 PVCR 0 Table 1 Peak-to-valley current ratio peak current and valley current at donor concentration inside Si with intrinsic Ge. 12.5 Valley current 12 11.5 11 10.5 10 3 4 5 6 7 8 9 10 doping concentration Figure 3 Valley current (µA) at different donor doping concentration (1018/cm3) inside Si with intrinsic Ge. 45 40 35 30 25 20 15 10 5 0 Peak current 3 4 5 6 7 8 9 10 doping concentration Figure 4 Peak current (µA) at different donor doping concentration (1018/cm3) inside Si with intrinsic Ge. From the Table 1, Figure 3 and Figure 4 it can be seen that the valley current increases on increasing the doping concentration whereas the peak current may increase or decrease on increasing the doping concentration of doping inside the Si. We get a high peak-to-valley current ratio of 3.735 at donor concentration of 7.5x1018/cm3 is achieved as shown in Figure 5. The peak current of 43.7µA is achieved at peak voltage 0.32V and the valley current of 11.7µA is achieved at 0.42V which corresponds to very high current density of 43.7mA/µm2 and 11.7mA/µm2 for peak and valley current respectively. The high current density is achieved due very short length of tunnel diode. The region from 0.32V to 0.42V shows negative differential resistance because current decreases on increasing the voltage. There is almost a constant current of 0.376nA in the reverse bias condition and 0.859nA reverse current at zero biasing voltage. We get a high peak-to-valley current ratio of 3.725 at donor concentration of 4.1x1019/cm3 is achieved as shown in Figure 6. The peak current of 50.3µA is achieved at peak voltage 0.311V and the valley current of 13.5µA is achieved at 0.408V which corresponds to very high current density of 50.3mA/µm2 and 13.5mA/µm2 for peak and valley current respectively. The high current density is achieved due very short length of tunnel diode. The region from 0.311V to 0.408V shows negative differential resistance because current decreases on increasing the voltage. There is almost a constant current of 0.377nA in the reverse bias condition and 0.281nA reverse current at zero biasing voltage. PVCR 3.735 PVCR 3.725 Peak Current (IP) 43.7µA Peak Current(IP) 50.3 µA Valley Current (IV) 11.7 µA Valley Current(IV) 13.5 µA IP - IV 32 µA IP - IV 36.8 µA Peak Voltage (VP) 0.32V Peak Voltage(VP) 0.311 V Valley Voltage (VV) 0.42V Valley Voltage(VV) 0.408 V VP - VV 0.1V VP - VV 0.097 V Maximum Reverse Current 0.376nA Maximum Reverse Current 0.377nA Current at zero bias voltage -0.859nA Current at zero bias voltage -0.281nA Table 2 Different parameter obtained from simulation at donor concentration 7.5x1018/cm3 inside Si with intrinsic Ge. 50 (µA) Anode Current Table 3 Different parameter obtained from simulation at donor concentration 4.1x1019/cm3 inside Si with intrinsic Ge. 60 (µA) Anode Current 50 40 40 30 30 20 20 10 10 Anode Voltage (V) 0 -0.2 -0.1 0 0.1 0.2 0.3 0.4 0.5 -10 Figure 5 Current-voltage characteristic of tunnel diode at doping concentration 7.5x1018/cm3 inside Si with intrinsic Ge showing PVCR of 3.735 at room temperature (Voltage is applied at Anode with grounded Cathode). Anode Voltage (V) 0 -0.2 -0.1 0 -10 0.1 0.2 0.3 0.4 0.5 Figure 6 Current-voltage characteristic of tunnel diode at doping concentration 4.1x1019/cm3 inside Si with intrinsic Ge showing PVCR of 3.725 at room temperature (Voltage is applied at Anode with grounded Cathode). Conclusion: The device shows almost constant reverse current at each doping concentration. The device have almost a constant Vp-Vv for all doping profiles and shows a varying PVCR. Maximum PVCR is observed at 7.5x1018/cm3 and 4.1x1019/cm3 which are 3.735 and 3.725. On increasing the doping concentration the valley current increases whereas peak current can increase or decrease. Due to small size of the tunnel diode it can be easily used in the SRAM, MOSFETs’ for reducing the size and enhancing the speed of the device. Since the difference between the peak voltage and valley voltage is very low (0.1V) hence it can be used in the high speed operation. References [1] J. P. Sun, G. I. Haddad, P. Mazumder, and J. N. Schulman, “Resonant tunneling Diodes: Models and Properties,” proceedings of the IEEE, VOL. 86, NO. 4, APRIL 1998. [2] N. Muramatsu, H. Okazaki, and T. Waho, “A Novel Oscillation Circuit Using a Resonant-Tunneling Diode,” Circuits and Systems, ISCAS 2005 IEEE International Symposium on pages: 2341 - 2344 Vol. 3, 2005. [3] T. Waho, T. Itoh, M. Yamamoto, “Ultra high-Speed Resonant Tunneling Circuits,” Second International Workshop on Physics and Modeling of Devices Based on Low-Dimensional Structures p.73, 1998. [4] International Journal Of Engineering And Computer Science ISSN: 2319-7242 Volume 2 Issue 12 December, 2013 Page No. 3580-3583. [5] J. Song, W. Dongmok, M. C. McAlpine, R. S. Friedman, W. Yue, and C. M. Lieber, “Scalable interconnection and integration of nanowire devices without registration,” Nano Letters, vol. 4, pp. 915919, 2004. [6] S. Perisanu, P. Vincent, A. Ayari, M. Choueib, S. T. Purcell, M. Bechelany, and D. Cornu, “High Q factor for mechanical resonances of batch-fabricated SiC nanowires,” Applied Physics Letters, vol. 90, 43113, 2007. [7] A. Husain, J. Hone, H. W. C. Postma, X. M. H. Huang, T. Drake, M. Barbic, A. Scherer, and M. L. Roukes, “Nanowire-based very-high-frequency electromechanical resonator,” Applied Physics Letters, vol. 83, pp. 1240 -1242, 2003. [8] R. Tu, L. Zhang, Y. Nishi, H. J. Dai, “Measuring the capacitance of individual semiconductor nanowires for carrier mobility assessment”, Nano Letters, vol. 7, pp. 1561-1565, 2007. [9] P. Sun, G. Haddad, “Resonant Tunneling Diodes: Models and Properties,” Proceedings of the IEEE, vol. 86, pp. 641-660, 1998. [10] H. Sheng, S. Chua, “Shot noise characteristics of a resonant tunneling diode,” J. Phys. D: Appl. Phys, vol. 27, pp. 137-141, 1994. [11] T. Akeyoshi, H. Matsuzaki, T. Itoh, T. Waho, J. Osaka, M. Yamamoto, “Applications of ResonantTunneling Diodes to High-Speed Digital ICs,” Indium Phosphide and Related Materials, vol. 11, pp. 405-410, 1999. [12] A. Afzalian, “A New Fast-CMS Algorithm for Efficient Three-Dimensional NEGF Simulations of Arbitrarily Shaped Silicon Nanowire MUGFETs” International Conference on Simulation of Semiconductor Processes and Devices, pp. 1-4, 2009.