TEAP - June 2015 Progress Report (Volume 1)

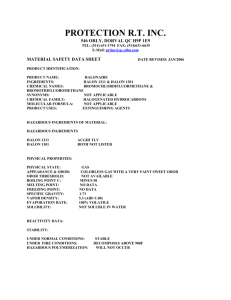

advertisement