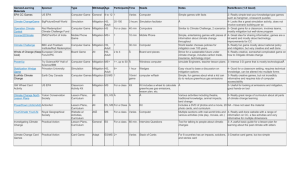

RISK ANALYSIS

advertisement

SCU-FEL RISK ANALYSIS Nov. 25, 2014 The SCU-FEL Risk Management Plan (RMP) conforms to the site-wide SLAC Risk Management Plan (SLAC-I-PMO-0005). The SLAC plan has incorporated lessons learned in several recent SLAC projects, including the LCLS project. The SCU-FEL RMP describes the risk identification and management approach. Some of the higher-level risks are identified below including their mitigation. 1. Schedule estimate inaccurate or not sufficiently mature leading to delay of LCLS-II project. Mitigation Measures: Include milestones for critical project dependencies in the baseline planning. Production might be increased to two shifts per day to overcome schedule slip. 2. The transverse alignment of adjacent undulator segments within a single cryostat must be very precise (~50 m) and well maintained during cryostat cool-down. Mitigation Measures: Prototype testing… ??? 3. The field integrals and phasing along each undulator segment must be precisely measured and corrected. Mitigation Measures: Experience at APS (SCU1) has shown that precise core machining and accurate conductor winding practices may eliminate the need to apply phasing corrections along the magnet. Magnet-prototype testing and, in the future, full cryostat-prototype testing… Independent correction magnets… HTS-tape field correction scheme will be tested on the magnet prototypes, but may not be necessary on the final production magnets. 4. The K-value (peak field) of each undulator segment must be controlled from segment to segment within ~0.03%, requiring very precise measurements. Mitigation Measures: Prototype testing… High-precision measurement tools… 5. A cold, high-resolution cavity beam position monitor (BPM) must be developed, which will likely be contained in the cold cryostat. Mitigation Measures: 1 Testing of existing cavity BPM in Dewar? The… 6. Beam-induced heat loads on the cryogenics system are not known with high confidence. Mitigation Measures: New calculations of the wakefield-induced heat loads have been completed which are applicable to a cold bore and an extremely short bunch length. The head load estimates are made for the absolute worst case conditions and we also include a large safety factor (~2) on the capacity of the cryogenics plant. 7. Experience at ANL on a 1-m long SCU suggests that ~100 quench cycles are needed to train the magnet up to full current, which would be a considerable slow-down in production. Mitigation Measures: The… The… 8. The present magnet correction schemes do not allow for out-of-plane trajectory corrections. Mitigation Measures: The… The… 9. The... Mitigation Measures: The… The… 10. The... Mitigation Measures: The… The… Risk identification and analyses will continue throughout the planning and execution processes. Each of the identified risks will be monitored to ensure they are effectively analyzed and handled as appropriate. The risks identified are used to assess the contingency. The risk-based contingency assessment will continue through the project lifecycle to ensure sufficient contingency to mitigate remaining risks. As appropriate, simulation tools will be utilized to gauge the risk-based cost and schedule contingencies. 2