Caltech, 2013-04-05

advertisement

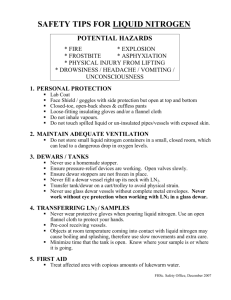

Pumping efficiency of activated carbon getters as a function of temperature. Roger Smith Caltech, 2013-04-05 Introduction The ability of activated carbon (charcoal) to adsorb air when cooled to liquid Nitrogen 77K or thereabouts is fundamental to the successful operation of cryogenic vacuum systems using elastomeric seals since all such seals allow some degree of gas permeation. For example, Viton, one of the better materials, allows about 0.5 µTorr-Liter/s of air to pass through each meter of O-ring length. Depending on dewar volume and O-ring length a typical astronomical detector dewar will experience a pressure rise rate between 1 and 10 mT/day (at room temperature). Eg. the dewar used for these tests has a vacuum volume around 6 liters, and about 2.5m of Viton O-ring length, resulting in a pressure rise rate (at room temperature around 0.6mT/hour, implying O-ring diffusion (plus any residual outgassing) is only 0.4µT-liter/s/m. Without a getter to adsorb this gas, pressures will be reached where gas conduction will dominate the thermal load in less than a day. An ion pump is an alternative to a getter but is expensive, requires power to operate, has to be baffled to block the light it emits, has limited capacity and life, and can be damaged by overload. Furthermore the ion pump’s self protection interlocks prevent it from turning on until the pressure gets low enough so the dewar has to be pumped longer before cooling than a charcoal getter which can be cooled from quite high pressures. Zeolites have also been used as getters but as they retain water vapor very efficiently at room temperature, they become saturated (poisoned) over time and thus lose their gas pumping capacity. Charcoal, by contrast, will desorb both air and water vapor at room temperature so that the mere act of warming and pumping the dewar is sufficient to regenerate its pumping capacity. They require no intervention by those operating the system. As a result of these features, it is common practice to locate a charcoal getter deep within the dewar at its coldest location, while also mounting a zeolite container in an easily removed container on the outer wall to act as a desiccant. In this configuration the charcoal is never saturated by pumping water and thus will pump air reliably. The zeolite may need to be removed and heated (we use a solder pot) to regenerate it, but this is usually only necessary during the early life of a dewar when water vapor may be outgassing or the dewar is exposed to humid air during commissioning activities. The problem Closed cycle Joule Thompson cryocoolers such as the Polycold Cryotiger or ARS Orca are being used in several instruments at Palomar and Keck observatories. For the Polycold with PT30 refrigerant, the getter temperature may be in the 130-140K range and not 77K as for liquid nitrogen cooled dewars. Does the getter bind Nitrogen and Oxygen sufficiently efficiently (or at all) at these temperatures? Literature on the pumping efficiency of activated carbon at these intermediate temperatures has not been found. Most data is focused on industrial refrigeration (food processing, water purification etc) or cryosorption pumps cooled by helium closed cycle coolers operating at well below liquid nitrogen temperature. The experiment In an ideal situation one would test adsorption capacity by mounting a getter on a thermally controlled platform while introducing various quantities of gas onto the dewar and measuring the pressure as a function of both getter temperature and gas load. In such an arrangement one could maintain a constant getter temperature for long periods to be assured that thermal and pressure equilibria have been reached. A simpler approach using existing equipment was adopted. Dry Nitrogen was introduced into a CCD dewar (Palomar’s DBSP-R), by first evacuating the plumbing between the dry Nitrogen cylinder and the dewar through a T-piece. After the valve to the pump was shut off, the valve from the gas cylinder was opened partially to allow a small amount of Nitrogen to enter the line, while monitoring the pressure in the line with a Granville Phillips Convectron (pirani) gauge. The valve to the Nitrogen cylinder was closed, then the valve to the dewar was opened to share the gas in the line with the dewar. This procedure was repeated to meter a controlled quantity of gas until the desired pressure in the dewar was reached. During this process, water vapor was prevented from entering the dewar by introducing pure Nitrogen via a closed path which had been pumped down. In addition a cold trap (liquid Nitrogen cooled bulb) was installed in the line to condense water and any organic molecules. Finally the zeolite desiccant in the dewar was present to adsorb any outgassed moisture evading the other measures. As testimony to the effectiveness, it was observed that the when the gas was finally removed from the dewar after the experiment, via a 2 meter length of 25mm diameter stainless steel vacuum hose to a turbo pump, the pressure in the dewar dropped from 10 Torr to less than 0.1mT in less than 2 minutes. This would not have been possible with any significant water vapor present. The dewar exhibited only 0.6mT/hour pressure rise after closing the dewar valve (averaged over 12 hours). Dewar pressure and temperature of the Nitrogen tank, to which the getter was connected, were logged to a file and graphed on a web page every minute for the duration of all experiments as shown in Figure 1 and Figure 2, and in detail in Figure 3. After partially filling with dry gas, the dewar was cooled with liquid Nitrogen as quickly as possible (about 6 minutes). In all cases the pressure dropped to “zero” (ie less then 0.1mT) on the Convectron gauge within 4 minutes of Nitrogen accumulation, thanks to the pumping action of the getter. Clearly the thermal time constant for the getter to settle to the tank temperature is on the order of minutes or less. Once thermal equilibrium was reached, the final boiloff rate was measured. The tank was then actively heated to dump the liquid Nitrogen: the tank heater servo’s setpoint was set to 79K, resulting in automatic shutdown of the heaters as soon as the liquid nitrogen was exhausted. Thereafter the tank warmed passively (initially 0.3K/min). At this low rate the getter temperature should have been within a degree or so of the tank temperature sensor, which was being logged. At ~130K the pressure began to rise sharply as the getter released the adsorbed gas. The resulting gas conduction caused the rate of temperature rise to increase. This intern resulted in gas being released more quickly. This accelerated temperature rise creates some uncertainty in the correlation between getter temperature (not measured directly) and the tank temperature (measured), however this error should be small at the onset of the gas release, the regime of most interest, since the gas pressure is still low. Figure 1: Tank/getter temperature (B) and radiation sheild (A) temperatures in Kelvin. Figure 2: Pressure measured by Granville Phillips Convectron (Pirani) gauge. Results Figure 1 shows temperature logs for the tank (sensor B) and radiation shield (sensor A), while Figure 2 shows the corresponding pressure versus time. In Figure 4, pressure is plotted verses getter (tank) temperature for each of the warm ups. The initial gas pressures in the IR-Labs ND5 dewar were 20mT, 850mT, 890mT and 10.6 Torr. The 20mT curve is suspect due to reduced accuracy of the Convectron gauge at low pressures. (Unfortunately our full range gauge was out for repair). Clearly charcoal getters do work at temperatures well above the boiling point of Nitrogen, confirming that carbon does indeed bind Nitrogen. Presumably the release of gas, beginning at 130K, occurs when the Van der Waals force is overcome by lattice vibration at that temperature. Figure 5 shows the fraction of gas released, on a linear scale. The data in Figure 4 has been normalized to the final pressure. A correction has been applied to scale each pressure that which would be observed if the gas released was at 295K. To produce a flat top at the upper temperatures (where the getter has released all the gas), it was found that the gas temperature would have to be 1/3 of the way between ambient and the tank temperature, which is quite reasonable given the geometry so this weighting was used to estimate the effect of the gas cooling on the pressure reading. Figure 3: First cooling and warming cycle. Note how the temperature slew rate increases as the gas is released by the getter at 12:30. Figure 4: Pressure versus temperature of the Nitrogen tank to which the getter container is attached. Figure 5: Fraction of the Nitrogen gas, which has been released. Data in figure 3 has been normalized by the final pressure and a correction for gas expansion has been applied to reference the pressure to that which would be seen if the gas warmed to room temperature. Pumping capacity Two to three hours after the dewar was filled, the boiloff rate was seen to settle to 1.7 standard cubic feet per hour, the normal boiloff for this dewar. This was so whether the starting pressure was 20mT, 850mT or 10.6 Torr. Clearly the ~20ml volume of activated carbon is capable of pumping even larger gas quantities to sufficiently low pressure. Given the observed room pressure rise rate due to O-ring permeation plus outgassing, 0.6mT/hour, and the ability of the getter to easily achieve normal boiloff rate after pumping down from 10.6 Torr, the dewar would need to be pumped only after intervals significantly exceeding 10.6T/(0.6mT/hour) = 2 years. Charcoal getters in Joule Thompson cooled dewars In PTF, a 250mm by 125mm CCD mosaic (15-18W load) is cooled by a single Polycold Compact Cooler with PT30 refrigerant. While the Polycold cooling curves promise a cold head temperature around 128K, the measured getter temperature is seen to be in the 139K to 142K range, where the getter begins to relase Nitrogen. The large getter volume in PTF <value?> offsets the getter inefficiency, and probably explains how we have achieved a vacuum service interval greater than 2 years. Nonetheless, it would be desirable to improve the safety margin by improving the thermal contact between the cold head and the heat spreader in which the getter is embedded. In an emergency we can run the CCDs slightly colder to reduce heater power flowing through the contact resistance of the joint between getter and cold head. For ZTF, which has a much larger focal plane area and two Polycold coolers, the getter temperature can be reduced by attaching the getter to the cold head by a separate path rather than placing the getter container between the thermal link to the detector and the cold head. In this way the heat extracted from the entire system will not flow through the getter to cold head joint, but will take a parallel path. With little power flow from getter to cold head in this configuration, the contact resistance will no longer be critical. In ZTF, a further 10K reduction in getter temperature might be achieved by switching to the PT16 gas, which reaches a lower ultimate temperature, albeit with a smaller power margin. A decision on this will depend on the final assessment of thermal load, which in turn depends on whether we will have field flatteners mounted on each CCD and thus awaits a decision on the optics.