Study guide for quiz 2

advertisement

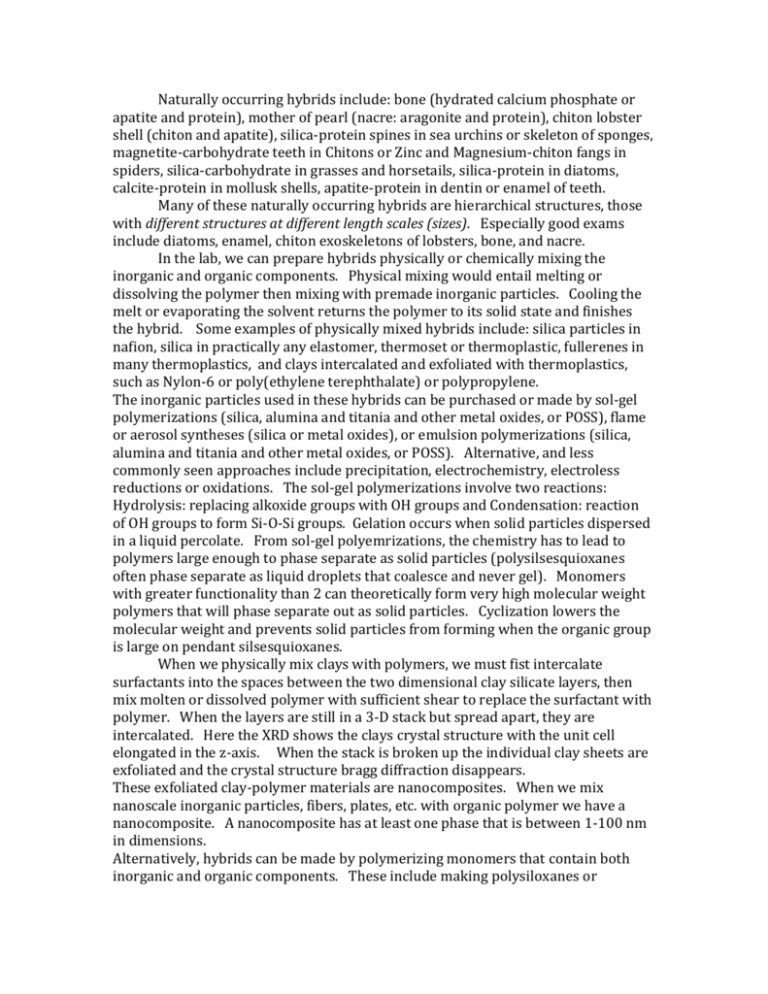

Naturally occurring hybrids include: bone (hydrated calcium phosphate or apatite and protein), mother of pearl (nacre: aragonite and protein), chiton lobster shell (chiton and apatite), silica-protein spines in sea urchins or skeleton of sponges, magnetite-carbohydrate teeth in Chitons or Zinc and Magnesium-chiton fangs in spiders, silica-carbohydrate in grasses and horsetails, silica-protein in diatoms, calcite-protein in mollusk shells, apatite-protein in dentin or enamel of teeth. Many of these naturally occurring hybrids are hierarchical structures, those with different structures at different length scales (sizes). Especially good exams include diatoms, enamel, chiton exoskeletons of lobsters, bone, and nacre. In the lab, we can prepare hybrids physically or chemically mixing the inorganic and organic components. Physical mixing would entail melting or dissolving the polymer then mixing with premade inorganic particles. Cooling the melt or evaporating the solvent returns the polymer to its solid state and finishes the hybrid. Some examples of physically mixed hybrids include: silica particles in nafion, silica in practically any elastomer, thermoset or thermoplastic, fullerenes in many thermoplastics, and clays intercalated and exfoliated with thermoplastics, such as Nylon-6 or poly(ethylene terephthalate) or polypropylene. The inorganic particles used in these hybrids can be purchased or made by sol-gel polymerizations (silica, alumina and titania and other metal oxides, or POSS), flame or aerosol syntheses (silica or metal oxides), or emulsion polymerizations (silica, alumina and titania and other metal oxides, or POSS). Alternative, and less commonly seen approaches include precipitation, electrochemistry, electroless reductions or oxidations. The sol-gel polymerizations involve two reactions: Hydrolysis: replacing alkoxide groups with OH groups and Condensation: reaction of OH groups to form Si-O-Si groups. Gelation occurs when solid particles dispersed in a liquid percolate. From sol-gel polyemrizations, the chemistry has to lead to polymers large enough to phase separate as solid particles (polysilsesquioxanes often phase separate as liquid droplets that coalesce and never gel). Monomers with greater functionality than 2 can theoretically form very high molecular weight polymers that will phase separate out as solid particles. Cyclization lowers the molecular weight and prevents solid particles from forming when the organic group is large on pendant silsesquioxanes. When we physically mix clays with polymers, we must fist intercalate surfactants into the spaces between the two dimensional clay silicate layers, then mix molten or dissolved polymer with sufficient shear to replace the surfactant with polymer. When the layers are still in a 3-D stack but spread apart, they are intercalated. Here the XRD shows the clays crystal structure with the unit cell elongated in the z-axis. When the stack is broken up the individual clay sheets are exfoliated and the crystal structure bragg diffraction disappears. These exfoliated clay-polymer materials are nanocomposites. When we mix nanoscale inorganic particles, fibers, plates, etc. with organic polymer we have a nanocomposite. A nanocomposite has at least one phase that is between 1-100 nm in dimensions. Alternatively, hybrids can be made by polymerizing monomers that contain both inorganic and organic components. These include making polysiloxanes or polysilanes from dichlorosilanes, polysilsesquioxanes from organotrialkoxysilanes, and polyphosphaazenes from hexachlorocyclotriphosphazene,

![LAB 4 FB Safety [BH]](http://s3.studylib.net/store/data/007109339_1-10edf2f99cf9e3f5eb5770ce96c065cf-300x300.png)