Analysis of Fatty Acid

advertisement

Supplementary Materials and Methods

Plasmid Construction

The plasmid pA58c-TR (Supplementary Figure 1) used for constructing the fatty acid producing E.

coli strain was constructed from pE8a-fadR and pKS1 using a modified Golden Gate DNA

assembly method (Steen et al., 2010; Zhang et al., 2012a; Zhang et al., 2012b). The araC gene

together with the PBAD-fadR operon from pE8a-fadR was PCR amplified using the following

primers: FZ_fRP5, TTTTTTGGTCTCACTCATTATGACAACTT GAC GGCTACATC; FZ_fRP3,

TTTTTTGGTCTCACGAAGCGGGGTTTTTTGCGTTTGGA TCCT TATCGCCCCTG. Similarly,

pKS1 was linearized by PCR amplification using the following primers: FZ_A5c3,

TTTTTTGGTCTCATGAGCGCAACGCAATTAATGTAAG;

FZ_A5c5,

TTTTTTGGTCTCATTCGGCGGGGTTTTTTCGCCGATCTTCCCCATCGGTGP CR. Products

were purified and followed by one-pot BsaI digestion and DNA T4 ligase ligation. A synthetic

terminator BBa_B1002 (Registry for Standard Biological Parts, http://partsregistry. org/Main_Page)

was split and embedded in both primer FZ_fRP3 and FZ_A5c5. Upon ligation, BBa_B1002 was

placed 3’ of the fadR gene. The E. coli fadR is under the control of PBAD. A truncated version of

the E. coli thioesterase gene tesA ('tesA; leader sequence deleted) is under the control of PlacUV5.

Composition of M9 MOPS Minimal Medium

M9 MOPS minimal medium (Neidhardt et al., 1974) was used in this study. The medium contained

per liter: 30 g [1,2-13C]glucose (99% isotopic purity, Sigma-Aldrich), 6.8 g Na2HPO4, 3.0 g

KH2PO4, 0.58 g NaCl, 3.96 g (NH4)2SO4, supplemented with 50 ml of 1 M MOPS with pH

adjusted to 7.4 with KOH, 1 ml of 1 M MgSO4, 1 ml of 0.1 mM CaCl2, 1ml of trace elemental

solution containing 2.4 g MnSO4·4H2O, 2.4 g ZnSO4·7H2O, 0.26 g CoCl2, 0.48 g CuSO4·5H2O,

0.24 g Na2MoO4·2H2O, 3 g H3BO3, 8.4 g FeSO4·7H2O, 20.6 g Na3EDTA per liter, 10 ml of RPMI1640 [100X] vitamin solution (R7256, Sigma-Aldrich) and 1 ml of 25 mg∙l-1 of chloramphenicol.

1

The supplements were filter-sterilized and added separately. All chemicals were purchased from

Sigma-Aldrich.

Analysis of Cell Growth and Growth Parameters

The optical density of the cell culture was measured on a Cary 60 UV-Vis spectrophotometer

(Agilent Technologies) at 600 nm (OD600). The relationship of dry cell weight (DCW) and OD600

was determined from 5 ml of chilled culture broth of known OD600 in triplicate (0.34 g·l-1·OD600-1

was determined). Exactly, the culture broth was centrifuged at 13,000 × g for 10 min at 4 °C,

washed three times with 0.9% NaCl, resuspended in 5 ml of double distilled water, and dried on a

pre-weighted aluminum plate at 90 °C to constant weight. Glucose and acetate concentrations were

measured using commercial kits (Roche). The rates of biomass formation, substrate consumption

and product formation were determined by linear regression of the concentrations of the

corresponding substances versus time during the exponential growth phase with the rates as the

regression coefficients (Sauer et al., 1999). The yields of biomass, fatty acid, and acetic acid on

glucose were determined as the regression coefficients of the concentrations of biomass, acetic acid,

and fatty acid versus the concentration of glucose during the time course of the exponential growth

phase. The biomass elemental compositions of the control and the engineered E. coli were assumed

to be the same and remained constant during cell growth (Leighty and Antoniewicz, 2012).

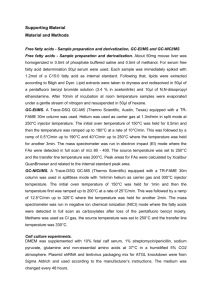

Analysis of Fatty Acid

175 μl of culture spiked with 100 mg∙l-1 of pentadecanoic acid (C15:0) as the internal standard was

acidified using 5 µl of concentrated HCl and extracted with 400 µl of methanol-chloroform (1:1).

The organic phase containing fatty acids separated by centrifugation was transferred to a new tube

and the solvent evaporated under vacuum. Fatty acids were methylated in a solution containing 10

µl of concentrated HCl, 20 µl of 2 M of (trimethyulsily) diazomethane solution and 170 µl of

methanol at 40 ºC for 2 h. The methyl esters of fatty acids were extracted by dual phase separation

in 200 µl of 0.9% NaCl and 350 µl of ethyl acetate and analyzed using a gas chromatograph mass

2

spectrometer (GC-MS) (Hewlett Packard 7890A and 5975C, Agilent Technologies) equipped with a

DB5-MS column (J&W Scientific). The GC-MS program was as follows: the column temperature

initially held at 80 ºC for 1 min, raised to 280 ºC at 30 ºC·min-1 and held at 280 ºC for 3 min.

Helium was used as the carrier gas. The mass spectra were analyzed using the Enhanced Data

Analysis software (Agilent Technologies). The fatty acids were quantified based on the standard

curve of methyl fatty acid (F.A.M.E. Mix, C8-C24, Sigma-Aldrich).

References

Neidhardt, FC, Bloch, PL, Smith, DF. 1974. Culture Medium for Enterobacteria. J Bacteriol

119:736-747.

Sauer, U, Lasko, DR, Fiaux, J, Hochuli, M, Glaser, R, Szyperski, T, Wüthrich, K, Bailey, JE. 1999.

Metabolic flux ratio analysis of genetic and environmental modulations of Escherichia coli

central carbon metabolism. J Bacteriol 181:6679-6688.

Steen, EJ, Kang, Y, Bokinsky, G, Hu, Z, Schirmer, A, McClure, A, del Cardayre, SB, Keasling, JD.

2010. Microbial production of fatty-acid-derived fuels and chemicals from plant biomass.

Nature 463:559-562.

Zhang, F, Carothers, JM, Keasling, JD. 2012a. Design of a dynamic sensor-regulator system for

production of chemicals and fuels derived from fatty acids. Nat Biotechnol 30:354-359.

Zhang, F, Ouellet, M, Batth, TS, Adams, PD, Petzold, CJ, Mukhopadhyay, A, Keasling, JD. 2012b.

Enhancing fatty acid production by the expression of the regulatory transcription factor FadR.

Metab Eng 14:653-660.

3