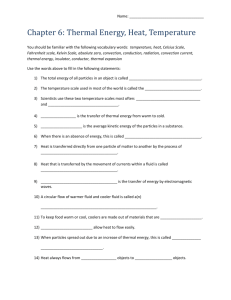

16081

advertisement

MULTIPHYSICS MODELLING OF VARIABLE CONFINEMENT COOKOFF TEST (VCCT) Dr. Charles Dubois Mr. Pierre Pelletier* Professor Chemical Engineering Department École Polytechnique de Montréal 2900 Boul. Édouard Montpetit Montréal, QC, Canada H3T 1J4 Special Project Manager General Dynamics Ordnance and Tactical System Canada Inc. 5 Montée des Arsenaux, Repentigny, QC, Canada, J5Z 2P4 ABSTRACT The overall objectives of this project were to built and assess multiphysics finite elements models for simulating cook-off experiments performed with the small scale variable confinement cook-off test (VCCT) apparatus. The COMSOL Multiphysics modelling software was selected to obtain a numerical description of the tests geometry and then employed to calculate the time evolution of temperature and pressure within the test sample for several energetic materials composition. This work was achieved by simultaneously solving the equation of changes for momentum, heat and mass transfer. In the latter case, kinetics models were incorporated to reflect the early decomposition of the energetic materials found in the system. Composition B, PBXN-109, CX-85 and IMX-104 high explosive formulations were simulated and the results were confronted to experimental results from VCCT conducted in GD-OTS Canada laboratories. Heat losses to the environment were accounted for by considering natural convection and radiant energy, using COMSOL’s built-in correlations to estimate the local heat transfer coefficient. Additional details such as solidsolid contact thermal resistance, melting enthalpies and temperature dependant physical properties were also included in the model. Whenever possible, the specific kinetics of the decomposition behavior of the energetic materials used was obtained from DSC measurements using an isoconversional analysis method. Different heating rates were simulated as part of this project. The analysis showed that simulated temperatures were close to experimental measurements from thermocouples positioned in the VCCT system. The estimations of time to onset of runaway reaction were also in good agreement with experimental data. As a whole, the study tends to confirm that a simulation approach could eventually be used as a screening tool to reduce the experimental workload associated with the assessment of thermal sensitivity of energetic materials and could be applied to full scale munitions following calibration of the model with small scale VCCT test. This simulation work has also been instrumental in the development of a modified version of the VCCT apparatus. * Point of contact for paper 16081 Pierre Pelletier General Dynamics Ordnance and Tactical Systems Canada (GD-OTS Canada) Tel: (450) 582-6345 Fax: (450) 582-9771 e-mail: Pierre.Pelletier@can.gd-ots.com 1 Multiphysics Modelling of Variable Confinement Cook-off Test (VCCT) 1. INTRODUCTION Studies to reduce the reaction level of high explosives when exposed directly or indirectly to heat sources has been motivated by major accidents involving undesired detonation of ordnance and ammunition that could happen at different moments in their life cycle. The development of the “Insensitive Munitions” (IM for short) concept was the subject of a sustained level of R&D activities over the past forty years and will remain of interest, as several countries are implementing IM policies. The means of validating the efforts invested in IM technologies are not so easily available however for those stimuli due to the elevated cost to realize them at full scale. In order to ensure that progress is made and could be assessed, a few reduced sample size protocols have been established to help in energetic material formulations development and preliminary selection prior to the performance of full scale standardized IM tests with the munitions of interest. NATO Standardization Agreement (STANAG) 4491 [1]) describes several explosives, thermal sensitiveness and explosiveness tests. One of them, “the Variable Confinement Test” (VCCT) has been implemented at GDOTS Canada in Repentigny following discussions with Defence Research and Development Canada (DRDC) Valcartier regarding their experience with such a test. No matter the scale however, one of the drawbacks of the cook-off experiments when medium and slow heating rates (typically 3.3 to 25°C/hr) are considered is the required duration time that can span over several hours. A numerical technique to estimate the detonation time in a VCCT assembly would therefore be a useful tool for planning cook-off experiments and obtain preliminary data. The goal of this work was to establish such simulation models and assess their accuracy. The simulation work was also instrumental in the development of an improved version of the test described in a related paper [2]. 2. BACKGROUND Heat transfer is a transit of thermal energy due to a temperature difference. It is customary to refer to three heat transfer modes: conduction, convection and thermal radiation. Figure 1 depicts the standard Variable Confinement Cook-off Test (VCCT) [1] setup with arrows representing the heat transfer modes at different locations. In the following section we will detail the mathematical treatment for each of these modes. FIGURE 1: Schematic view of the standard VCCT setup and corresponding heat transfer modes 2 In order to remain general in the treatment of the problem, we refrained from using an axisymmetric modeling framework, to reflect the fact that experimental conditions (such as uneven heat source or localized contact with a metallic surface) may bring asymmetry in the internal temperature profiles. 2.1. Theoretical framework and simulation approach The heat diffusion through a solid can be simply expressed by a 3D generalization of Fourier’s law [2]: Cp T k 2T t (1) In this work we considered the density, the heat capacity and the conductivity to be a function of temperature (T). In order to solve equation (1), appropriate boundary conditions must be provided [3, 4]. Three scenarios were encountered in our case: a) For a solid A to solid B interface where the thermal contact resistance can be neglected, the conditions were continuity of heat flux and temperature: TA = TB qA = qB (2) b) The contact between two surfaces is never perfect therefore a discontinuity in the temperature profile of an assembled part may exist. For a solid A to solid B interface where the thermal contact resistance cannot be neglected; this is expressed by the following equations [2]: q hc T1 T3 xA 1 x B k A A hc A k B A 1 AC 2k AkB AV kf Lg A k A kB A (3) (4) c) For solid (A) to fluid (C) interface with convection and thermal radiation may take place:, the Newton cooling law was assumed to apply: kA dT dx q hA(Tw T ) F FG A TW4 TS4 (5) W In equation (5), the heat transfer coefficient h has to be estimated. This is often done using correlations considering the following factors [2]: Nu hD f Re,Pr M Rea Pr b k (6) 3 The values of M, a and b in (6) are correlation specific and depend on the shape of the surface, its orientation, etc…In our model, the correlations were taken from the built-in coefficients library in COMSOL software [5] and were directly calculated based on geometrical factors and fluid conditions when the boundary condition “convective cooling” was incorporated in the model. The other circumstance where convection needed to be considered was when the sample tested in the VCCT experiment was a melt pour explosive with a relatively low melting temperature such as Composition B or IMX-104. When the energetic material undergoes a phase change, the computational domain is no longer purely a solid and also contains a liquid component. Even in the absence of mechanical action or pressure effect, the fluid can be put in motion due to the temperature induced density gradient in the sample. If a primary vertical motion is assumed, the general form of the energy transport equation for a system under natural convection conditions is given by the following equations [4]: Z component of the equation of motion v z v z v v z v z 2u vr vz g T T t r r z y 2 inertia (7) buoyancy viscous forces energy equation T T v T T k vr vz t r r z Cp convection 1 r r 2 2 T 1 T T r r r 2 2 z 2 (8) conduction It is observed that these two partial differential equations (PDE) are coupled through the variable T. Therefore, under conditions of natural convection, equations (7) and (8) have to be solved simultaneously. One additional difficulty of considering the convection during the melting process is the fact that the relative fraction of liquid to solid increases with time. In order to avoid using advanced meshing techniques, it was decided to solve the equations of motion over the entire cylindrical shape of the sample, but to depict the non-molten portion of the explosive as a fluid of very high viscosity, and thus artificially prevent its movement by effect of natural convection. Therefore, a smoothed step function in the viscosity was used to approximate the melting process. For example, in the case of Composition B, the viscosity function used was: 50 for T 80C (Pa.s ) 7391 273.15 T 17.6 for T 80C (9) In order to account for the large amount of energy involved with the melting process when a melt pour composition is heated in the VCCT set-up, an approach inspired from the work of Groulx et al [6] was put in place. This was accomplished by introducing a discontinuity in the specific heat Cp of the material [7, 8]. In the case of the Composition B formulation, as used in this study, the enthalpy of fusion with a value of 11.149 kJ/kg (8 cal/g) [7] was used and we assumed that the melting process occurs over a 3K temperature 4 range (from 352 K to 355 K) in order to avoid having strong non-linearity in the system of equations to solve. The specific heat of the explosive was therefore modified in the following way: 921.3 3.929T 0.06354T 2 J kg C Cp 11149 J kg C for 79C T 82C 2 1483.9 9.698T 0.1150T J kg C for T 82C (10) Another melt cast explosive considered in this work, IMX-104, contains about 32% of DNAN. The latent heat of DNAN has been reported to have a value of 99 kJ/kg [9], and therefore IMX-104 overall latent heat was estimated at 31.7 kJ/kg. Again, if one assumes that the melting process occurs over a 3K temperature range (from 365 K to 368 K), the specific heat of the explosive can be expressed in the following way: 2.25T 862.5 J kg C for 20C T 94C Cp 11636 J kg C for 94C T 96C 2.25T 862.5 J kg C for 96C T 200C (11) In order to perform adequately the computer simulations, several physical properties were required. Those were readily obtained from open sources publications and therefore, the details are not reported here. Results of cook-off experiments are normally described in terms of the level of the reaction observed in the sample. This event is a macroscopic evidence of a process taking place at the molecular level. As the sample is gradually heated up, the energetic materials begin to decompose. These degradation reactions are accompanied by thermal effects. As for any chemical reaction, the heat involved in the process can be released (exothermic) or absorbed (endothermic). In the case of an exothermic process, the energy released by the chemical reaction will serve to heat up the material even more. This, in turn, will increase the rate of the degradation and thus liberate a larger amount of energy. An autocatalytic effect associated to exothermic reactions that may result in a thermal runaway event (or eventually an explosion) is therefore observed if no special measures are taken to cool the decomposing sample. The modelling of a decomposition process can be conducted either as a mechanistic or an empirical point of view. Empirical models depict the decomposition process as either a single step or a few steps reaction and no information is sought about the chemical species involved in the transient states of the materials. For the purpose of this work, we used both approaches. When available from the literature, data for stepwise reactions involved in the decomposition process have been used and, in some instances, completed by additional DSC experiments. It is possible to summarize the use of kinetics and thermal data in the modelling of a cook-off experiment by considering a hypothetical energetic material that decomposes in three consecutive steps, as shown in equation (12). Each of these steps will normally involve a heat of reaction which can be either positive or negative. According to chemical thermodynamics, when the heat transport equation is applied to an experimental sample, it needs to be modified to include a source term (W/m3) combining the heat effects of these three reactions, as shown in equations (13) and (14): Q3 Q1 Q2 A B C D (12) 5 Cp T k 2T q t (13) q 1 riQi (14) 3 where: Qi = the molar heat of reaction (J/mole) Ri = reaction rate (mole/m3.s) The reaction rates are expressed empirically by an “n” order kinetics: dCi k iCini dt (15) and the effect of the temperature on the rate constant is assumed to follow an Arrhenius relation: ki Zi e Eai RT (16) Therefore, the first step in attempting to simulate the thermal effects associated with the decomposition of an energetic material is to obtain a stepwise kinetics model of the process. Obviously, the number of “i” equations has to be adjusted to a specific formulation or energetic material. For the purpose of this work, some of these models are already available in the literature for both melt pour (composition B) and cast cure (PBXN-109) explosives, while for more recent formulations, such as IMX-104 (melt pour) and CX-85 (cast cure), we used DSC analysis to characterize the decomposition process. There are different approaches to obtain kinetics information from DSC data. This method used to obtain the kinetics models from DSC experiments will be the subject of a future paper since its applicability and limitations are still being studied. Table 1 : Kinetics parameter for PBXN-109 decomposition [10] ln Zi (s-1) Eai (kJ/mol) ni Q/ (J/g) AB (solid) 43.7 197 1 268 B2C (gas) 38.9 185 1 -803 2C2D (gas) 32.7 143 2 -6560 Table 2 : Apparent kinetics parameters for IMX-104 decomposition process ln Zi (s-1) Eai (kJ/mol) Q/ (J/g) AB 56 253 -742 BC 34 155 -934 6 3. Experimental studies For the purpose of verifying and calibrating the simulation and modelling process, experimental data from VCCT were collected in a large variety of environmental conditions, materials and sample types. A set of three experiments will be described here and then compared with the modelling results. The first experiment consisted in heating a Teflon cylinder inserted in the VCCT thermal sleeve. The cylinder was drilled in order to insert two thermocouples and monitor the temperature in the sample as a function of time. Two surface thermocouples were also located on the VCCT endplates while two other surface thermocouples were positioned at mid-height of two opposite retaining bolts. A schematic of the thermocouples positions is given in Figure 2 a). FIGURE 2: Schematic of a) the original VCCT and b) modified VCCT set-up used at GD-OTS Canada – Repentigny. The second and third experiments discussed were conducted in a modified VCCT test set-up shown in Figure 2 b). The second experiment used Composition B as an energetic material and the sample was submitted to a medium heating rate test using the following steps: a) a 3°C/min temperature sample pre-heating ramp for 30 minutes, b) a plateau at 108°C for about 1 hour for “soaking” of the sample, and then a 0.5°C/min ramp until detonation. The third experiment was performed with IMX-104 as the explosive sample and it was submitted to a fast heating rate. 4. Simulations and results The calculated values for the temperatures at positions where experimental data were available are presented in Figure 3 for the VCCT experiment conducted on the inert Teflon sample. The purpose of this test was to assess the correctness of the COMSOL heat transfer models in the VCCT arrangement regardless of any other effects such as sample decomposition or sample melting process. A general examination of the figure shows that 7 there is a fairly good agreement between the calculated values and experimental data, even though it may seem to be not as good for thermocouples located on extended surfaces of the set-up, i.e. the endplates and retaining bolts. This can be explained by the fact that these thermocouples are positioned far from the heating elements. In the VCCT set-up, heat flows from the confinement sleeves to the endplates, who act as extended surface to dissipate thermal energy. Several thermal resistances are found along the path of these streamlines: material thermal conductivities, thermal contact resistances and heat transfer coefficients. Accordingly, since these resistances are essentially in a serial configuration, all the errors in estimating them will be cumulative. Therefore, the farther the position of interest is from the heating bands, the more likely the calculated temperature at this point deviates from the experimental observation. Another distinctive feature apparent from these data is the effect of having the VCCT setup standing on a metallic surface. It is clearly seen that the bottom endplate is always at a lower temperature than the upper endplate. 250 200 Temperature (oC) 150 CH1 CH2 CH3 Probe A Probe C Probe B 100 Probe D paroi centre offset A 50 C B 0 0 5000 10000 15000 20000 25000 Time (s) FIGURE 4: Intermediate heating rate experiment conducted on a TEFLON sample: Experimental (lines) and calculated values (markers) The comparison between simulated and experimental cook-offs for Composition B is presented in Figures 5. An inspection of Figure 5 b), where the concentration in decomposition products of the explosive is presented shows that the initiation point of the runaway reaction occurs at the mid-height of the sample, near or at the surface of the sample. When modelling for fast heating rates, the concentration profiles are a better indicator of the reaction onset than the temperature, since the simulation never converges when the exponential temperature raise really starts up. A comparison of the calculated and measured temperatures at three points on the VCCT test arrangement gives a good agreement between the two sets of data The COMSOL model overestimates the onset time by about 15 % (Figure 5 a)). 8 FIGURE 5: a) Calculated (line) and measured (symbols) surface temperatures of a Composition B cook-off experiment under a fast heating rate at t= 115 sec (calculated onset); and b) Calculated decomposition products concentration at onset The assessment of the COMSOL models against the experimental data for cook-off tests on IMX-104 samples is presented in Figure 6 for a medium heating rate. The initiation point is clearly at the center of the sample, as shown on part b), while part a) indicates that the calculated time to reach detonation is underestimated by only a few minutes. FIGURE 6 a) Calculated (line) and measured (symbols) surface temperatures of a IMX-104 cook-off experiment under a medium heating rate at t= 18700 sec (calculated onset); and b) Calculated midplane temperature profile at onset The calculated slow cook-off experiment for the 105mm shell is presented in Figure 7. Only one internal temperature of the sample was experimentally available for comparison purposes. It is seen that the agreement with the model is rather good in terms of the sample temperature, while the time to achieve detonation is slightly underestimated. 9 FIGURE 7: Calculated and measured temperatures in a Composition B filled 105 mm shell during a cook-off experiment (lines end at cook-off event). 5. Conclusion The work presented in this paper summarizes recent efforts aimed at conducting a finite elements based modeling exercise of the VCCT experiments and on a standard artillery projectile. The use of COMSOL simulation environment software proved to be particularly convenient for this task, mainly because of the built-in heat coefficient library and the availability of a dedicated Heat Transfer module. The multi-physics capability of COMSOL is also an asset for carrying out a simultaneous solution of heat and momentum transport problems, such as the one encountered during the slow heating cycle of a melt-cast explosive formulation such as Composition B. The modelling process was successful in predicting the time-dependent temperature profiles in the VCCT assembly when used with a Teflon sample, as confirmed from experimental data for medium and fast heating rate cycle. Similar calculations were also conducted on a virtual Composition B sample, but for these simulations, no experimental temperature values inside the sample were available to validate the numerical results. A mathematical model representing the melting process as a pulse in the heat capacity of the sample material is believed to provide a physically sound approximation of the phase change. When employed in the simulation of the VCCT experiment, the model provided a description of the transient melting process along with internal motion due to internal convection. While the results presented in this paper are encouraging, it must be recognized that a complete simulation of the cook-off experiment will require additional efforts to include the chemical reactions associated to the thermal degradation. It is our intend to investigate these aspects by considering PBXs. For doing so, the heat of reaction should be included as a source term in the equation energy and the mechanical effect of the gas evolved from the decomposition process will be considered by a structural analysis of the sample confinement in the VCCT set-up. 10 6. References [1] The North Atlantic Treaty Organization (NATO) Standardization Agreement (STANAG) #4491 Explosives, Thermal sensitiveness and Explosiveness tests, August 2002. [2] F. P. Incropera, F.P., Introduction to Heat Transfer, 5th edition, Wiley, New York, USA, 2006. [3] R. W. Lewis R.W., Ken Morgan, K.,, H. R. Thomas H.R., Seetharamu, K., The Finite Element Method in Heat Transfer Analysis, Wiley, New York, USA, 1996. [4] Bird, R.B., Warren E. Stewart, W.E., Edwin N. Lightfoot, E.N.,, Transport Phenomena (2nd ed), John Wiley & Sons, 2001. [5] COMSOL - Heat transfer module User Guide [6] Groulx, D., Ogoh, W., “Solid-Liquid Phase Change Simulation Applied to a Cylindrical Latent Heat Energy Storage System”, Proceedings of the COMSOL Conf., Boston, USA, 2009. [7] Determination of cooling of Comp-B Poured 81mm and 120mm mortar shells by thermocouples and by finite element thermal model, AMSTA-AR-QAT-T, 28 [8] Vasilakis, J.D., Computer Model for the Solidification of Composition B, Technical Report ARCCB-TR-85003, December 1985. [9] Davies, P.J., Provatas, A., Characterisation of 2,4-Dinitroanisole: An Ingredient for use in Low Sensitivity Melt Cast Formulations, DSTO-TR-1904, Defence Science and Technology Organisation, Weapons Systems Division, 2006. [10] McClelland, M.A., Tran, T.D., Cunningham B.J., Weese, R.K., Maienshein, J.L., Cookoff Response of PBXN-109: Material Characterization and ALE3D Thermal Predictions, . JANNAF CS/APS/PSHS Joint Meeting, Monterey, 2000. 11 Presenter biography: Pierre Pelletier Pierre Pelletier graduated from Laval University in Quebec City Canada in chemical engineering in 1980 and then worked for Defence Research Establishment Valcartier before joining Canadian Arsenals in 1987 which changed name over years and acquisition processes to become General Dynamics Ordnance and Tactical Systems Canada. He obtained a master in mechanical engineering from Carleton University in Ottawa in 1995. Along with R&D work on explosives processing and filling of different types of munitions with melt-pour, cast-cure and pressed explosives, he has been involved in studies related to the terminal ballistics of fragmentation, shaped charge and EFP cartridges. Since 2005, he is heading the GD-OTS Canada R&D section involved in insensitive munitions development studies and development covering energetic materials processing and testing, munitions and packaging design, IM testing. His interests out of the job are skiing (alpine and cross-country), jogging, sailing, kayaking, reading and classical music listening. He enjoys watching Canadian universities football and is also a keen supporter of the Laval University football team. 12