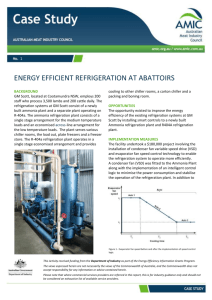

Thermodynamics of refrigeration

advertisement