MEC317 L3 - Liquid Viscosity & Drag on Sphere

advertisement

LAB 3:

LIQUID VISCOSITY AND

DRAG ON A SPHERE

Tuesday April 15th, 2014

Kanchan Bhattacharyya – First Author, Discussion and Conclusion

Xie Zheng – Theory, Experimental Procedure, and List of Equipment

Matthew Stevens – Introduction and Results

Ting Zhang – Abstract, Error Analysis

Group 4

ABSTRACT

This experiment mainly consists of three parts. Students are firstly required to learn to determine

the viscosity of liquid by using the falling ball. Next they are asked to learn to measure the drag force

coefficient of a sphere in the same fluid. Finally, students illustrate the way these data can be applied to

other fluid and other combinations. In this experiments, a bunch of variables are required to be measured

or calculated in order to calculate dynamic viscosity of fluid and drag coefficient of sphere. They are

density of sphere 𝜌𝑠 , density of liquid 𝜌𝑓 , sphere diameter d, container diameter D, velocity of sphere in

container as D approaches infinity 𝑈∞ , measured ball velocity 𝑈𝑡 . From the results we got, the

experiment data are in good accuracy when compared to theoretical data.

INTRODUCTION

The discipline of fluid mechanics covers everything from the aerodynamics of planes and

spacecraft to the mechanics of biological organisms. Because fluid flow phenomenon can include a wide

variety of media of varying properties Engineers generally subdivide fluid mechanics with regards to two

principle parameters, their viscous nature and compressibility. [1]

Viscosity is a measure of a fluid’s resistance to flow, and is largely dependent on the

temperature of the fluid. The presence of viscous effects explain everything from the drag experienced

by a ball throw into the air or when you drop it in a beaker of Glycerol , and many relationships have

been derived that give us an ability to quantity the presence of these viscous effects in terms of

measurable variables. The most notable of which, the Reynolds Number, describes the relationship

between the inertial effects and viscous effects of fluid. A dimensionless quantity, it is named after

Osborn Reynolds who after exhaustive experiments in the 1880’s discovered that flow regime depends

mainly on the ratio of these effects[2]. The magnitude of the Reynolds Number quantifies the presence

of viscous effects in a flow, with small Reynolds numbers less than 0.1 signifying fluids dominated such

effects. Small Reynolds numbers have been found to quantify the viscous nature of many fluid

phenomena, including those such as a biological virus moving in water[3] or the motion of bubbles in

channels and tubes [4].

While fluid motion can be complex, use of parameters such as the Reynolds Number allow for

quantification of fluid phenomena regardless of the nature of fluid or object traveling through the fluid.

For example, we can use the Reynolds Number to assess the true viscous nature of a fluid via analysis of

the motion of an object traveling through the fluid regardless of the nature of the fluid or the traveling

object. We find that the power of the Reynolds Number lies in this versatility, and can be used in any

scenario to describe the nature of fluid flow.

LIST OF EQUIPMENT

Stopwatch

Electrical Caliper

Model #: C-521

Manufacturer: KOBALT

Filter to guide the spheres to the

center of the tube

Specimen: three spheres

Testing device

Level

Model #:7724 Manufacturer: Johnson Level & Tool MPG. Co., Inc

THEORY

Viscosity Measurements

The viscosity of a fluid is a measure of its resistance to gradual deformation by shear stress or

tensile stress. Viscosity is due to the friction between neighboring particles in a fluid that are moving at

different velocities. In this experiment, we are dropping spheres into the liquid along the center line of a

container filled with the test liquid. By measuring the time that spheres travel between lines, the

velocity of the sphere will be determined. Once the velocity of the sphere is determined, the dynamics

viscosity of fluid could be simply obtained through an expression:

µ𝑓 =

(𝜌𝑠 − 𝜌𝑓 )𝑔𝑑2

(Eq.1)

18𝑈∞

where

µf

= dynamic viscosity of fluid

ρs

= density of sphere

ρf

= density of liquid

g

= acceleration of gravity

d

= sphere diameter

D

= container diameter

U∞

= velocity of sphere in container as D goes to infinity

Ut

= measured ball velocity

Since the experiment is processed inside a tube with finite diameter, U∞ should be corrected

into Ut. Here, we use the following wall-correction expression:

𝐶𝑊 =

𝑈𝑡

𝑈∞

𝑑 9⁄

4

= (1 − 𝐷)

(Eq.2)

Also, the Reynolds number must be less than 0.1 to perform the Eq.1

𝑅𝑒𝑡 =

𝜌𝑓 𝑈𝑡 𝑑

µ𝑓

(Eq.3)

Sphere Drag

To do the force analysis on the sphere, the balance of the force could be found in the following

equation:

4

𝜋𝑅 3 𝑔 (𝜌𝑠

3

− 𝜌𝑓 ) = 𝐹𝐷

(Eq.4)

By rearranging Eq.1, we can rewrite Eq.4 into:

𝐹𝐷 = 6𝜋µ𝑈∞ 𝑅

(Eq.5)

The drag coefficient, CD, is defined as the drag force divided by the cross sectional area of the

sphere and the kinetic energy of the ball:

𝐶𝐷 =

𝐹𝐷

1

2

𝐴𝐶𝑆 𝜌𝑓 𝑈∞ 2

(Eq.6)

Plug Eq.5 into Eq.6, we can get:

𝐶𝐷 =

12µ𝑓

𝑅𝜌𝑓 𝑈∞

(Eq.7)

If we let d = 2R, the drag coefficient, CD, could be rewrite as:

𝐶𝐷 =

24

𝑅𝑒∞

(Eq.8)

Alternative Equation for Dynamic Viscosity from Fig. 3 of Ref. 6:

(Eq. 9)

PROCEDURE

Since the experiment was already setup in the lab, we check the connections of the equipment and

make sure we have all the instruments we need. Before testing, we used level to make sure the tube is

vertical, measured the inside diameter of the tube with caliper and the distances between the circle line

on the tube. We also measure the temperature of the glycerol right before and after the experiment.

After recording the readings, we placed a filter at the top of the tube to make sure the balls

would fall down along the center line of the tube. We dropped the first ball which is largest and record

the time duration when it went through the lines and wrote down the readings. And then we dropped

the second one and the third one and recorded the time duration as well. Then, we took out all the

three balls for other trials by repeat the above steps until we get all the five trials.

Once we finished, we cleaned up the lab and put everything back.

RESULTS

Table 1. Description of Sphere Parameters

Number Designation

Description

Density, ρs (kg/m3)

Diameter, d (mm)

1

2

3

Red Plastic - Large

Steel - Large

Steel - Small

3990 ± 2%

8000 ± 2%

8040 ± 2%

3.173 ± 1%

3.169 ± 1%

1.583 ± 1%

Table 1. The assigned number designation, description, given density, and diameter of each of the

respective test spheres.

Table 2. Description of Glass Tube Testing Segments

Number Designation

Length, l (cm)

1

24.6

2

25.5

3

25.2

Table 2. Recorded Lengths of each of the segments comprising the testing tube.

Table 3. Glass Test Tube Inner Diameter

Measurements

Measurement Number

Diameter, D (mm)

1

46.01

2

46.6

3

46.6

4

46.15

Average

46.34

Table 3. Recorded Diameters for various cross sections of the circular tube. An average value was

calculated to be used in analysis.

Table 4. Glycerol Temperature Measurements

Measurement Number

Description

Temperature, T (°C)

1

Before Experiment

23

2

After Experiment

24

Table 4. Recorded Glycerol temperatures taken before and after the experiment.

9

𝑈𝑡

𝑑 4

𝑊𝑎𝑙𝑙 𝐶𝑜𝑟𝑟𝑒𝑐𝑡𝑖𝑜𝑛 𝐹𝑎𝑐𝑡𝑜𝑟, 𝐶𝑤 =

= (1 − )

𝑈∞

𝐷

9

3.173𝑚𝑚 4

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 1, (1 −

) = .85

46.34𝑚𝑚

9

3.169𝑚𝑚 4

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 2, (1 −

) = .85

46.34𝑚𝑚

9

1.583𝑚𝑚 4

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 3, (1 −

) = .92

46.34𝑚𝑚

Fig. 1 Calculation of Wall Correction Factors

The calculation of the respective wall correction factors for each sphere using Equation 2. The diameters

for each sphere and the Tube diameter can be found in Table 1 and Table 3.

Table 5. Average Wall Correction Factors for Respective Spheres

Number Designation

Wall Correction Factor, CW

1

0.85

2

0.85

3

0.92

Table 5. Calculated wall correction factors to be used to calculate respective terminal velocities for each

respective sphere.

Table 6. Sphere 1 Velocity Calculations for Segment 2

Trial

Time, t (sec)

Velocity, Ut (m/s)

Terminal Velocity, U∞ (m/s)

1

2

3

4

5

Average

15.47

15.42

15.47

15.50

15.25

15.42

1.65E-02

1.65E-02

1.65E-02

1.65E-02

1.67E-02

1.65E-02

1.93E-02

1.94E-02

1.93E-02

1.93E-02

1.96E-02

1.94E-02

Table 6. Recorded Traversing times and calculated sphere 1 tube and terminal velocities through the

second tube segment.

Table 7. Sphere 1 Velocity Calculations for Segment 3

Trial

Time, t (sec)

Velocity, Ut (m/s)

Terminal Velocity, U∞ (m/s)

1

16.78

1.50E-02

1.76E-02

2

16.50

1.53E-02

1.79E-02

3

16.66

1.51E-02

1.77E-02

4

16.47

1.53E-02

1.79E-02

5

16.50

1.53E-02

1.79E-02

Average

16.58

1.52E-02

1.78E-02

Table 7. Recorded Traversing times and calculated sphere 1 tube and terminal velocities through the

third tube segment.

Table 8. Sphere 1 Velocity Calculations

Trial

Segment

Terminal Velocity, U∞ (m/s)

1

2

2

2

1.93E-02

1.94E-02

3

2

1.93E-02

4

2

1.93E-02

5

2

1.96E-02

1

3

1.76E-02

2

3

1.79E-02

3

3

1.77E-02

4

3

1.79E-02

5

3

1.79E-02

Average

1.86E-02

Table 8. A comprehensive listing of all the calculated terminal velocities in Tables 6 and 7. This average

terminal velocity will be used in calculation of both the Reynolds Number and the drag coefficient of

first sphere.

𝐸𝑥. 𝑆𝑝ℎ𝑒𝑟𝑒 𝑂𝑛𝑒, 𝑆𝑒𝑔𝑚𝑒𝑛𝑡 𝑇𝑤𝑜, 𝑇𝑟𝑖𝑎𝑙 𝑂𝑛𝑒

𝑈𝑡 =

𝑔𝑖𝑣𝑒𝑛 𝐶𝑤 =

𝐷 0.0255 𝑚

𝑚

=

= 1.65 𝑥 10−2

𝑡

15.47 𝑠

𝑠

𝑈𝑡

𝑈∞

↔

𝑈∞ =

𝑈𝑡

𝑚

= 1.93 𝑥 10−2

𝐶𝑤

𝑠

Fig 2. Calculation of Sphere Tube and Terminal Velocities

The procedures for calculating tube velocity considering the length of each segment and time taken for

the sphere to traverse that distance and the terminal velocity considering the respective wall correction

factors.

Table 9. Sphere 2 Velocity Calculations for Segment 2

Trial

Time, t (sec)

Velocity, Ut (m/s)

Terminal Velocity, U∞ (m/s)

1

6.38

4.00E-02

4.69E-02

2

6.20

4.11E-02

4.82E-02

3

6.33

4.03E-02

4.72E-02

4

6.22

4.10E-02

4.81E-02

5

6.21

4.11E-02

4.82E-02

Average

6.27

4.07E-02

4.77E-02

Table 9. Recorded Traversing times and calculated sphere 2 tube and terminal velocities through the

second tube segment and the procedure from Fig. 2 (Calculation of Tube and Terminal Velocities)

Table 10. Sphere 2 Velocity Calculations for Segment 3

Trial

Time, t (sec)

Velocity, Ut (m/s)

Terminal Velocity, U∞ (m/s)

1

6.81

3.74E-02

4.39E-02

2

6.72

3.79E-02

4.45E-02

3

6.62

3.85E-02

4.52E-02

4

6.55

3.89E-02

4.57E-02

5

6.61

3.86E-02

4.52E-02

Average

6.66

3.83E-02

4.49E-02

Table 10. Recorded Traversing times and calculated sphere 2 tube and terminal velocities through the

third tube segment and the procedure from Fig 2. (Calculation of Tube and Terminal Velocities)

Table 11. Sphere 2 Average Terminal Velocity Calculations

Trial

Segment

Terminal Velocity, U∞ (m/s)

1

2

2

2

4.69E-02

4.82E-02

3

2

4.72E-02

4

2

4.81E-02

5

2

4.82E-02

1

3

4.39E-02

2

3

4.45E-02

3

3

4.52E-02

4

3

4.57E-02

5

3

4.52E-02

Average

4.63E-02

Table 11. A comprehensive listing of all the calculated terminal velocities in Tables 9 and 10. This

average terminal velocity will be used in calculation of both the Reynolds Number and the drag

coefficient of second sphere.

Table 12. Sphere 3 Velocity Calculations for Segment 2

Trial

Time, t (sec)

Velocity, Ut (m/s)

Terminal Velocity, U∞ (m/s)

1

22.94

1.11E-02

1.20E-02

2

22.97

1.11E-02

1.20E-02

3

22.66

1.13E-02

1.22E-02

4

22.72

1.12E-02

1.21E-02

5

22.35

1.14E-02

1.23E-02

Average

22.73

1.12E-02

1.21E-02

Table 12. Recorded Traversing times and calculated sphere 3 tube and terminal velocities through the

second tube segment and the procedure from Fig 2. (Calculation of Tube and Terminal Velocities)

Table 13. Sphere 3 Velocity Calculations for Segment 3

Trial

Time, t (sec)

Velocity, Ut (m/s)

Terminal Velocity, U∞ (m/s)

1

24.99

1.02E-02

1.10E-02

2

24.99

1.02E-02

1.10E-02

3

24.62

1.04E-02

1.12E-02

4

24.39

1.05E-02

1.13E-02

5

24.01

1.06E-02

1.15E-02

Average 24.60

1.04E-02

1.12E-02

Table 13. Recorded Traversing times and calculated sphere 3 tube and terminal velocities through the

third tube segment and the procedure from Fig 2. (Calculation of Tube and Terminal Velocities)

Table 14. Sphere 3 Average Terminal Velocity Calculations

Trial

Segment

Terminal Velocity, U∞ (m/s)

1

2

2

2

1.20E-02

1.20E-02

3

2

1.22E-02

4

2

1.21E-02

5

2

1.23E-02

1

3

1.10E-02

2

3

1.10E-02

3

3

1.12E-02

4

3

1.13E-02

5

3

1.15E-02

Average

1.17E-02

Table 14. A comprehensive listing of all the calculated terminal velocities in Tables 12 and 13. This

average terminal velocity will be used in calculation of both the Reynolds Number and the drag

coefficient of third sphere.

Table 15. Average Terminal Velocities for Respective Spheres

Number Designation

Description

Avg. Terminal Velocity, U∞ (m/s)

1

Red Plastic - Large 1.86E-02

2

Steel - Large

4.63E-02

3

Steel - Small

1.17E-02

Table 15. A comprehensive listing of the calculated average terminal velocities for each sphere taken

from Tables 8, 11, and 14. These velocities were used in determination of the respective Reynolds

Numbers and drag coefficients for each sphere.

𝐸𝑥. 𝐶𝑎𝑙𝑐𝑢𝑙𝑎𝑡𝑖𝑜𝑛 𝑜𝑓 𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑇𝑒𝑟𝑚𝑖𝑛𝑎𝑙 𝑉𝑒𝑙𝑜𝑐𝑖𝑡𝑦

̅∞ =

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 1, 𝑈

∑ U∞

𝑁

𝐿𝑒𝑡 𝑁 = 𝑁𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑀𝑒𝑎𝑠𝑢𝑟𝑒𝑚𝑒𝑛𝑡𝑠 = 10

∑ U∞ = U∞ 1 + ⋯ + U∞ 𝑁 =

(1.93 𝑥 10−2 𝑚/𝑠) + (1.94 𝑥 10−2 𝑚/𝑠) + ⋯ . +(1.79 𝑥 10−2 𝑚/𝑠)

= 1.86 𝑥 10−1 𝑚/𝑠

∑ U∞ 1.86 𝑥 10

̅∞ =

𝑈

=

𝑁

10

−1 𝑚

𝑠 = 1.86 𝑥 10−2 𝑚/𝑠

Fig 3. Procedure for Calculating Average Terminal Velocities for Respective Spheres

An example of how the average terminal velocity was calculated for each sphere using the data taken

from the sphere 1 trials as an example sample set. The data used can be found in Table 8. The same

procedure was extended to the calculation of the terminal velocities for spheres 2 in Tables 11 and 14.

𝐶𝑜𝑛𝑠𝑖𝑑𝑒𝑟 𝑘𝑛𝑜𝑤𝑛 𝑑𝑒𝑛𝑠𝑖𝑡𝑖𝑒𝑠 𝑜𝑓 𝐺𝑙𝑦𝑐𝑒𝑟𝑜𝑙 𝑎𝑡 𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒𝑠 𝑇0 = 20°𝐶 𝑎𝑛𝑑 𝑇1 = 30°𝐶

𝑘𝑔

𝑎𝑡 𝑇0 = 20°𝐶, 𝜌0 = 1,264.02 𝑚3

𝑘𝑔

𝑎𝑡 𝑇1 = 30°𝐶, 𝜌1 = 1,258.09 𝑚3

𝐵𝑦 𝐿𝑖𝑛𝑒𝑎𝑟 𝐼𝑛𝑡𝑒𝑟𝑝𝑜𝑙𝑎𝑡𝑖𝑜𝑛, 𝑤𝑒 𝑐𝑎𝑛 𝑓𝑖𝑛𝑑 𝑡ℎ𝑒 𝐷𝑒𝑛𝑠𝑖𝑡𝑦 𝑜𝑓 𝐺𝑙𝑦𝑐𝑒𝑟𝑜𝑙 𝑓𝑜𝑟 { 𝑇𝑓 | 20°𝐶 < 𝑇𝑓 < 30°𝐶 }

𝐶𝑜𝑛𝑠𝑖𝑑𝑒𝑟 𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒 𝑜𝑓 𝑡ℎ𝑒 𝐺𝑙𝑦𝑐𝑒𝑟𝑜𝑙 𝑏𝑒𝑓𝑜𝑟𝑒 𝑡ℎ𝑒 𝑒𝑥𝑝𝑒𝑟𝑖𝑚𝑒𝑛𝑡, 𝑇𝑓 = 23℃

𝑘𝑔

𝑘𝑔

𝜌1 − 𝜌0

𝑘𝑔 1,258.09 𝑚3 − 1,264.02 𝑚3

(𝑇 − 𝑇0 ) = 1,264.02 3 +

(23°𝐶 − 20°𝐶)

𝜌 = 𝜌0 +

𝑇1 − 𝑇0

𝑚

30°𝐶 − 20°𝐶

𝜌 = 1,262.241 𝑘𝑔/𝑚3

Fig 4. Procedure for Calculating Glycerol Temperature Tf via Linear Interpolation

Given known values of the density of Glycerol for various temperatures from Table A-4 on Page A3-1 of

the Manual, the density of the glycerol during the experiment can be calculated via linear interpolation

as seen above. Using the recorded temperature of 23°C, we can estimate the corresponding density

using known values for 20°C and 30°C.

𝜇𝑓 =

(𝜌𝑠 −𝜌𝑓 )𝑔𝑑 2

18𝑈∞

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 1:

𝑘𝑔

𝑘𝑔

𝜌𝑠 = 3,990 𝑚3 , 𝜌𝑓 = 1,262.241 𝑚3 ,

𝑔 = 9.81

𝑚

𝑚

, 𝑑 = 3.173 𝑥 10−3 𝑚, 𝑈∞ = 1.86 𝑥 10−2

2

𝑠

𝑠

𝑘𝑔

𝑚

(3990 − 1,262.241) ( 3 ) 𝑥 9.81 2 𝑥 (3.179 𝑥 10−3 𝑚)2

𝑁∙𝑠

𝑚

𝑠

𝜇𝑓 =

= 0.804

−2

18 𝑥 1.86 𝑥 10 𝑚/𝑠

𝑚2

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 2:

𝜌𝑠 = 8,000

𝑘𝑔

,𝑑

𝑚3

= 3.169 𝑥 10−3 𝑚, 𝑈∞ = 4.63 𝑥 10−2

𝑘𝑔

𝜇𝑓 =

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 3:

𝑚

(8000−1,262.241)( 3 ) 𝑥 9.81 2 𝑥 (3.169 𝑥 10−3 𝑚)

𝑚

𝑠

18 𝑥 4.63 𝑥 10−2 𝑚/𝑠

𝑚

𝑠

2

= 0.796

𝑘𝑔

𝜌𝑠 = 8,040 𝑚3 , 𝑑 = 1.583 𝑥 10−3 𝑚, 𝑈∞ = 1.17 𝑥 10−2

𝑁∙𝑠

𝑚2

𝑚

𝑠

𝑘𝑔

𝑚

(8000 − 1,262.241) ( 3 ) 𝑥 9.81 2 𝑥 (1.583𝑥 10−3 𝑚)2

𝑁∙𝑠

𝑚

𝑠

𝜇𝑓 =

=

0.793

18 𝑥 1.17 𝑥 10−2 𝑚/𝑠

𝑚2

Fig 5. Calculation of Dynamic Fluid Viscosity via Experimental Values

The Dynamic viscosity of the Glycerol was calculated using Equation 1 and the respective experimental

data collected for each sphere.

Table 16. Dynamic Viscosity Calculated from the Stokes Equation

Dynamic Viscosity, μ (N·s/m2)

Number Designation

1

0.804

2

0.796

3

0.793

Table 16. A comprehensive listing of the Dynamic Viscosity of the Glycerol calculated using the

procedure in Fig 5 above.

𝐶𝑜𝑛𝑠𝑖𝑑𝑒𝑟 𝜇(𝑇) = 5.06710 − 0.28266𝑇 + 5.4336 𝑥 10−3 𝑇 2 − 3.30493𝑥10−5 𝑇 3

𝑓𝑜𝑟 𝑇 = 23℃, 𝜇(𝑇)

= 5.06710 − 0.28266𝑥(23℃) + 5.4336 𝑥 10−3 𝑥(23℃)2 − 3.30493𝑥10−5 𝑥(23℃)3

𝑁∙𝑠

= 1.04 𝑚2

𝑓𝑜𝑟 𝑇 = 24℃, 𝜇(𝑇)

= 5.06710 − 0.28266𝑥(24℃) + 5.4336 𝑥 10−3 𝑥(24℃)2 − 3.30493𝑥10−5 𝑥(24℃)3

= 0.96

𝑁∙𝑠

𝑚2

Fig 6. Procedure for determining Dynamic Viscosity as a Function of Temperature as Per Equation 9

An illustration of the steps used to calculate the predicted Dynamic Viscosity of Glycerol as a Function of

Temperature considering the temperature of the Glycerol both before and after the experiment was

conducted.

Table 17. Dynamic Viscosity Calculated as a Function of Temperature

Measurement Number

Temperature, T (°C)

Dynamic Viscosity, μ (N·s/m2)

1

2

23

24

1.04

0.96

Table 17. A comprehensive collection of the Dynamic Viscosities of the Glycerol calculated in Fig 6. using

Eq. 9

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 1

𝜌𝑓 = 1,262.241

𝑘𝑔

𝑚

𝑁∙𝑠

, 𝑈∞ = 1.86 𝑥 10−2 , 𝑑 = 3.173 𝑥 10−3 𝑚, 𝜇𝑓 = 0.804 2 , 𝐶𝑤 = 0.85

3

𝑚

𝑠

𝑚

𝑘𝑔

−2 𝑚

−3

𝜌𝒇 𝐶𝑤 𝑈∞ 𝑑 (1,262.241 𝑚3 ) 𝑥 (0.85) 𝑥 (1.86 𝑥 10 𝑠 )(3.173 𝑥 10 )

𝑅𝑒𝑡 =

=

= 2.50 𝑥 10−1

𝑁∙𝑠

𝜇𝑓

. 804 2

𝑚

3

−2 𝑚

−3

𝜌𝒇 𝑈∞ 𝑑 (1,262.241 𝑘𝑔/𝑚 )𝑥 (1.86 𝑥 10 𝑠 )(3.173 𝑥 10 )

𝑅𝑒∞ =

=

= 2.93 𝑥 10−1

𝑁∙𝑠

𝜇𝑓

0.804 2

𝑚

Fig 7. Calculation of Respective Reynolds Numbers for Sphere 1

An illustration of the procedure used to calculate the Reynolds number for the first sphere using the

shown variables calculated from experimental results.

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 2,

𝜌𝑓 = 1,262.241

𝑘𝑔

𝑚

𝑁∙𝑠

, 𝑈∞ = 4.63 𝑥 10−2 , 𝑑 = 3.169 𝑥 10−3 𝑚, 𝜇𝑓 = 0.796 2 , 𝐶𝑤 = 0.85

3

𝑚

𝑠

𝑚

𝑘𝑔

−2 𝑚

−3

𝜌𝒇 𝐶𝑤 𝑈∞ 𝑑 (1,262.241 𝑚3 ) 𝑥 (0.85) 𝑥 (4.63 𝑥 10 𝑠 )(3.169 𝑥 10 )

𝑅𝑒𝑡 =

=

= 1.26

𝑁∙𝑠

𝜇𝑓

0.796 2

𝑚

𝑘𝑔

−2 𝑚

−3

𝜌𝒇 𝑈∞ 𝑑 (1,262.241 𝑚3 ) 𝑥 (4.63 𝑥 10 𝑠 )(3.169 𝑥 10 )

𝑅𝑒∞ =

=

= 1.47

𝑁∙𝑠

𝜇𝑓

0.796 2

𝑚

Fig 8. Calculation of Respective Reynolds Numbers for Sphere 2

An illustration of the procedure used to calculate the Reynolds number for the second sphere using the

shown variables calculated from experimental results.

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 3,

𝜌𝑓 = 1,262.241

𝑘𝑔

𝑚

, 𝑈∞ = 1. .17 𝑥 10−2 , 𝑑 = 1.583 𝑥 10−3 𝑚,

3

𝑚

𝑠

𝜇𝑓 = 0.793

𝑁∙𝑠

, 𝐶 = 0.92

𝑚2 𝑤

𝑘𝑔

−2 𝑚

−3

𝜌𝒇 𝐶𝑤 𝑈∞ 𝑑 (1,262.241 𝑚3 ) 𝑥 (0.92) 𝑥 (1.17 𝑥 10 𝑠 )(1.583 𝑥 10 )

𝑅𝑒𝑡 =

=

= 1.73 𝑥 10−1

𝑁∙𝑠

𝜇𝑓

0.793 2

𝑚

𝑘𝑔

−2 𝑚

−3

𝜌𝒇 𝑈∞ 𝑑 (1,262.241 𝑚3 ) 𝑥 (1.17 𝑥 10 𝑠 )(1.583 𝑥 10 )

𝑅𝑒∞ =

=

= 1.87 𝑥 10−1

𝑁∙𝑠

𝜇𝑓

0.793 2

𝑚

Fig 9. Calculation of Respective Reynolds Numbers for Sphere 2

An illustration of the procedure used to calculate the Reynolds number for the second sphere using the

shown variables calculated from experimental results.

Table 18. Reynolds Number Calculations

Number Designation

Reynolds Number, Ret

Reynolds Number, Re∞

1

2.50E-01

2.93E-01

2

1.26

1.47E

3

1.73E-01

1.87E-01

Table 18. A comprehensive listing of the calculated Reynolds numbers in Figures 7, 8, and 9.

4

𝑇ℎ𝑒 𝐷𝑟𝑎𝑔 𝐹𝑜𝑟𝑐𝑒 𝑜𝑛 𝑡ℎ𝑒 𝑆𝑝ℎ𝑒𝑟𝑒 𝐹𝐷 = 𝜋𝑅 3 𝑔(𝜌𝑠 − 𝜌𝑓 )

3

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 1, 𝑅 =

𝑑

2

=

3.173 𝑥 10−3

2

𝑘𝑔

𝜌𝑓 = 1,262.241 𝑚3 , 𝑈∞ = 1.86 𝑥 10−2

𝐹𝐷 =

𝑚

𝑘𝑔

= 1.5865 𝑥 10−3 𝑚, 𝑔 = 9.81 𝑠2 , 𝜌𝑠 = 3,990 𝑚3 ,

𝑚

𝑠

4

𝑚

𝑘𝑔

𝑥 (𝜋) 𝑥 (1.5865 𝑥 10−3 )3 𝑥 (9.81 2 ) 𝑥 (3,990 − 1,262.241) 3

3

𝑠

𝑚

= 4.48 𝑥 10−4 𝑁

𝑇ℎ𝑒 𝐷𝑟𝑎𝑔 𝐶𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡 𝑜𝑓 𝑡ℎ𝑒 𝑆𝑝ℎ𝑒𝑟𝑒

𝐶𝐷 =

2𝐹𝐷

𝜌𝑓 𝑈∞ 2 𝜋𝑅 2

=

2 𝑥 (4.48 𝑥 10−4 𝑁)

𝑘𝑔

𝑚

(1262.241 3 ) 𝑥 (1.86 𝑥 10−2 𝑠 ) 𝑥 𝜋 𝑥 (1.5865 𝑥 10−3 )2

𝑚

= 258.91

Fig 10. Calculation of the Drag Force and Drag Coefficient of Sphere 1

An illustration of the procedure used to calculate the drag force and drag coefficient of sphere 1 as per

Eq. 5 and 6.

4

𝑇ℎ𝑒 𝐷𝑟𝑎𝑔 𝐹𝑜𝑟𝑐𝑒 𝑜𝑛 𝑡ℎ𝑒 𝑆𝑝ℎ𝑒𝑟𝑒 𝐹𝐷 = 𝜋𝑅 3 𝑔(𝜌𝑠 − 𝜌𝑓 )

3

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 2, 𝑅 =

𝑑

2

=

3.169𝑥 10−3

2

𝑘𝑔

𝜌𝑓 = 1,262.241 𝑚3 , 𝑈∞ = 4.63 𝑥 10−2

𝐹𝐷 =

𝑚

𝑘𝑔

= 1.5845 𝑥 10−3 𝑚, 𝑔 = 9.81 𝑠2 , 𝜌𝑠 = 8,000 𝑚3 ,

𝑚

𝑠

4

𝑚

𝑘𝑔

𝑥 (𝜋) 𝑥 (1.5845 𝑥 10−3 )3 𝑥 (9.81 2 ) 𝑥 (8,000 − 1,262.241) 3

3

𝑠

𝑚

= 1.10 𝑥 10−3 𝑁

𝑇ℎ𝑒 𝐷𝑟𝑎𝑔 𝐶𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡 𝑜𝑓 𝑡ℎ𝑒 𝑆𝑝ℎ𝑒𝑟𝑒

𝐶𝐷 =

2𝐹𝐷

𝜌𝑓 𝑈∞ 2 𝜋𝑅 2

=

2 𝑥 (1.10 𝑥 10−4 𝑁)

𝑘𝑔

𝑚

(1262.241 3 ) 𝑥 (4.63 𝑥 10−2 𝑠 ) 𝑥 𝜋 𝑥 (1.5845 𝑥 10−3 )2

𝑚

= 103.17

Fig 11. Calculation of the Drag Force and Drag Coefficient of Sphere 2

An illustration of the procedure used to calculate the drag force and drag coefficient of sphere 2 as per

Eq. 5 and 6.

4

𝑇ℎ𝑒 𝐷𝑟𝑎𝑔 𝐹𝑜𝑟𝑐𝑒 𝑜𝑛 𝑡ℎ𝑒 𝑆𝑝ℎ𝑒𝑟𝑒 𝐹𝐷 = 𝜋𝑅 3 𝑔(𝜌𝑠 − 𝜌𝑓 )

3

𝑓𝑜𝑟 𝑆𝑝ℎ𝑒𝑟𝑒 1, 𝑅 =

𝑑

2

=

1.583𝑥 10−3

2

𝑘𝑔

𝜌𝑓 = 1,262.241 𝑚3 , 𝑈∞ = 1.17 𝑥 10−2

𝐹𝐷 =

𝑚

𝑘𝑔

= 0.7915 𝑥 10−3 𝑚, 𝑔 = 9.81 𝑠2 , 𝜌𝑠 = 8,040 𝑚3 ,

𝑚

𝑠

4

𝑚

𝑘𝑔

𝑥 (𝜋) 𝑥 (0.7915 𝑥 10−3 )3 𝑥 (9.81 2 ) 𝑥 (8,040 − 1,262.241) 3

3

𝑠

𝑚

= 1.38 𝑥 10−3 𝑁

𝑇ℎ𝑒 𝐷𝑟𝑎𝑔 𝐶𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡 𝑜𝑓 𝑡ℎ𝑒 𝑆𝑝ℎ𝑒𝑟𝑒

𝐶𝐷 =

2𝐹𝐷

𝜌𝑓 𝑈∞ 2 𝜋𝑅 2

=

2 𝑥 (1.38 𝑥 10−4 𝑁)

𝑘𝑔

𝑚

(1262.241 3 ) 𝑥 (1.17 𝑥 10−2 𝑠 ) 𝑥 𝜋 𝑥 (0.7915 𝑥 10−3 )2

𝑚

= 816.02

Fig 12. Calculation of the Drag Force and Drag Coefficient of Sphere 3

An illustration of the procedure used to calculate the drag force and drag coefficient of sphere 3 as per

Eq. 5 and 6.

Table 19. Drag Force Coefficient Calculations

Number Designation

Drag Force, FD (N)

Drag Coefficient, CD

1

4.48E-04

258.91

2

1.10E-03

107.12

3

1.38E-04

816.02

Table 19. A Comprehensive listing of the respective drag forces and coefficients calculated for each

sphere as per Figs. 10, 11, and 12.

Table 20. Comparison of the Drag Coefficient and Reynolds Number

Number Designation

Reynolds Number, Re∞

1

2

3

2.93E-01

1.47E

1.87E-01

Drag Coefficient, CD

259.91

103.20

816.02

Table 20. A Comprehensive comparison of the Calculated values for the Reynolds Numbers, Re∞ given in

Table 18 and the Drag Coefficients CD given in Table 19 for each respective sphere.

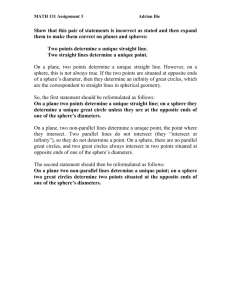

Drag Coefficient vs. Reynolds Number

100000

Sphere 3

Sphere 2

10000

Drag Coefficient, CD

Sphere 1

1000

100

10

1.00E-03

1.00E-02

1.00E-01

1

1.00E+00

Reynolds Number, Re

Fig 13. Log-Log Plot of Drag Coefficient CD vs. Reynolds Number Re∞ for respective spheres

The Calculated Drag Coefficients plotted against the calculated Reynolds Numbers for each sphere on a

Log-Log Plot.

DISCUSSION

This experiment compares

obtained experimentally using the Stokes Equation formulation in

Eqn 1 with those predicted from the best-fit polynomial curve obtained from Eqn 9, where

is

reported as a function of temperature T. Given that Eqn 1 was derived for the case of a sphere falling in

an infinite wide medium, a correction factor from Eqn 2. is used to adapt experimental velocities in the

tank to the infinite width velocities needed in Eqn 1. 3 different

can be obtained, one for each

sphere, each with its own density and diameter.

These can then be used to calculate drag forces on each sphere, which are then plotted on a loglog plot against

to generalize a curve that can predict either quantity for any sphere of given

density and diameter, as long as

< 0.1. is met, which is the second objective of this experiment.

Looking at Table 1, which lists the parameters for each sphere, two comparisons can be made:

(1) the large steel sphere vs. the small steel sphere and (2) the large red plastic sphere vs. the large steel

sphere. For (1), since both are steel the densities are roughly equivalent while the diameter is roughly

halved going from large to small. The effect of halving the diameter while holding the density constant

can be seen in the effect on the average terminal velocities reported in Table 15 for each sphere. In this

case, the effect is that halving the diameter while holding the density constant results in a nearly 4x drop

(from 4.63E-03 to 1.17E-03 or 3.96x) in velocity, strongly illustrating that velocity is related to the square

of “d”, the diameter, which confirms one aspect of the Stokes Equation formulation in Eqn 1. For (2) both

have roughly the same diameter but the density of plastic is roughly half that of steel. Referring back to

Table 15, the effect is that halving the density while holding the diameter constant results in a nearly

2.5x drop (from 4.63E-03 to 1.86E-03, or 2.48x) in velocity, which is not perfectly linear but far from

quadratic in terms of the relation between velocity and density, again strongly confirming the validity of

Eqn 1. From this simple analysis of terminal velocities, it appears that the relationships between

quantities in Eqn 1 corresponds to experimental results.

Once the constant parameters and data for terminal velocities from Tables 6 through 15 are

inputted into Eqn 1, average experimental dynamic viscosities for each sphere can be obtained which

are tabulated in Table 16. The red plastic sphere had a dynamic viscosity of 0.804 N·s/m2 the large steel

sphere had 0.796 N·s/m2, and the small steel sphere had 0.793 N·s/m2. Since the terminal velocities used

were all averaged from 2 segments and 5 trials of data, these values have a lot of data backing them up

and appear fairly consistent around 0.800 N·s/m2for the experimental dynamic viscosity, across all 3

spheres.

Comparing these with the dynamic viscosity calculated from Eqn 9, where the viscosity

predicted at the starting room temperature 23℃ was 1.04 N·s/m2 and at the final room temperature at

24 ℃ was 0.96 N·s/m2. This set of values is also fairly consistent around 1.00 N·s/m2, but most likely

because the rise in temperature was only 1 degree. That being said, there is a roughly 20% difference

between the experimental dynamic viscosities calculated using Eqn 1 and those calculated from the Fig 3

Eqn in the reference, that needs to be addressed.

Discussing minor experimental factors first, looking at Eqn 1 it can be seen that there is an

inverse dependence on

. This quantity is obtained from

using a correction factor for finite width.

It may be that the result of averaging velocities from Segment 2 and Segment 3 in the tube resulted in

an average velocity higher than the true terminal velocity which may decrease the value of

.

However, a more plausible experimental issue that also lends to great uncertainty is the use of

the correction factor. The correction factor accounts for differences in

and

with infinite width

assumptions. In most trials, the spheres did not fall in a perfectly linear path collinear with the center of

the tube. The sphere often descended at a slant approaching the wall of the tube and it’s reasonable to

think that coming closer to the wall than expected may result in wall effects that are greater than

expected for dropping the sphere in a tube of this width. Qualitatively, the fluid lines around the sphere

can abruptly intersect with the wall surface and disrupt movement of the sphere, if it fails to fall down

the center. It is not clear if the correction factor used would take into consideration extra wall effects

that arise from the ball not falling down the center. In such a case, the correction factor would have to be

closer to 1, which yields a smaller

and a higher dynamic viscosity.

Putting experimental issues aside, Eqn 1 allows us to compute dynamic viscosities in terms of

our specific experimental parameters. This is in the spirit of what is known as a Falling Ball Viscometer.

Eqn 9 computes dynamic viscosities as a function of temperature, a relation derived from using a

“Falling Needle Viscometer” type setup, which tries to avoid some uncertainties of sphere diameter,

density, and finite medium problems. The slight difference in the use of needles or thin cylinders as the

dropped object over spheres lends a greater degree of accuracy for Eqn 9 than our setup which is more

affected by these uncertainties. Therefore, the latter equation may likely yield the better absolute

dynamic viscosity values for the fluid, however, with regards to the spheres dropped in our experiment

that follow slanted trajectories and such, the experimental dynamic viscosities we obtain are still

consistent.

Lastly, examining the log-log plot in Fig 13, which plots the log of the

against the log of the

, the three spheres fall on the linear portion of the graph, with the large steel sphere (Sphere 2)

approaching a region that drops sharply. With the experimental data at present, it isn’t clear exactly

what combination of

and

will mark the transition into the turbulent region, however, this curve

can be used to interpolate for a variety of sphere diameters and densities that fall between the range of

the large steel sphere (Sphere 2) and the small steel sphere. (Sphere 3) Further sphere diameter and

density combinations can be used to mark the point where the log-log plot no longer stays linear, at

which point our founding equations need to be re-examined. This can also be verified using the

constraint on Eqn 1, which is given in Eqn 3 where

< 0.1.

ERROR ANALYSIS

1. Calculate the uncertainties of measured times:

Use data from Table sphere 1 for segment 2 as an example:

Governing equation:

∆x = t 𝑣,𝑝 ∗

𝑆𝑋

√𝑁

= 2.77 ∗

0.10035

√5

= 0.1243

We only did only five trials in measuring the time, which is less than 60 trials, so we use values of Student

Distribution table in lab manual in order to get the value of ∆t 𝑣,𝑝 . After referring to Table 1, we decided to

use 95% as our confidence intervals, besides v =N-1=5-1=4, so t 𝑣,𝑝 = 2.77. Sx is value of standard

distribution.

Example answer for

𝑡 = 15.42 ± 0.1243(95%)

sphere 1 for segment 2

sphere 2 for segment 2

sphere 3 for segment 2

Trial

Time, t (sec)

Trial

Time, t (sec)

Trial

Time, t (sec)

1

15.47

1

6.38

1

22.94

2

15.42

2

6.2

2

22.97

3

15.47

3

6.33

3

22.66

4

15.50

4

6.22

4

22.72

5

15.25

5

6.21

5

22.35

Average

15.42

Average

6.268

Average

22.73

Sx

0.10035

Sx

0.08167

Sx

0.25054

tv,p

2.77

tv,p

2.77

tv,p

2.77

∆x

0.12431174

∆x

0.101171298

∆x

0.310364357

sphere 1 for segment 3

Trial

Time, t (sec)

sphere 1 for segment 3

Trial

Time, t (sec)

sphere 1 for segment 3

Trial

Time, t (sec)

1

16.78

1

6.81

1

24.99

2

16.50

2

6.72

2

24.99

3

16.66

3

6.62

3

24.62

4

16.47

4

6.55

4

24.39

5

16.50

5

6.61

5

24.01

Average

16.58

Average

6.66

Average

24.60

Sx

0.13349

Sx

0.10281

Sx

0.10281

tv,p

2.77

tv,p

2.77

tv,p

2.77

∆x

0.165364964

∆x

0.127359142

∆x

0.127359142

Table 1: This table lists the experimental data and their corresponding values which are used to calculate

uncertainties for time such as average values, standard deviation values, tv,p and uncertainties for time t

for sphere 1, 2 and 3 respectively.

2. Calculate the uncertainties for Ut

Governing equation:

𝑈𝑡 =

∆𝑈𝑡 = √(

𝑙

𝑡

2

2

𝜕𝑈𝑡

𝜕𝑈𝑡

𝑙

∆𝑙) + (

∆𝑡) = √0 + (− 2 ∆𝑡)2

𝜕𝑙

𝜕𝑡

𝑡

Use sphere 1 for segment 1 as an example

𝜕𝑈

2

𝜕𝑈

2

𝑙

25.4

∆𝑈𝑡 = √( 𝜕𝑙𝑡 ∆𝑙) + ( 𝜕𝑡𝑡 ∆𝑡) = √0 + (− 𝑡 2 ∆𝑡)2 = √(− 15.422 ∗ 0.1243)2 = 0.1534

sphere1

mean(mm/s)

∆x(mm/s)

sphere2

mean(mm/s)

∆x (mm/s)

v (seg1)

16.5

0.1534

v(seg1)

40.7

0.7317

v(seg2)

15.2

0.1516

v(seg2)

38.3

0.7231

Ut

15.85

0.1525

Ut

39.5

0.7274

sphere 3

mean(mm/s)

∆x (mm/s)

v(seg1)

11.2

0.0537

v(seg2)

10.4

0.0530

Ut

10.8

0.0534

Table 2: This table lists the data that is used to calculate uncertainties for Ut for sphere 1, 2 and 3

respectively.

3.Calculate the uncertainties for 𝑈∞

Governing equations:

𝑈∞ =

𝑈𝑡

𝑑

(1 − )9/4

𝐷

a. According to the equation above which is derived by using propagation, we need to find out the value

of ∆𝐷

Use data from Table sphere 1 for segment 2 as an example:

Governing equation:

∆D = t 𝑣,𝑝 ∗

𝑆𝑋

√𝑁

= 3.182 ∗

0.30561

√4

= 0.4862

We only did only four trials in measuring the time, which is less than 60 trials, so we use values of Student

Distribution table in lab manual in order to get the value of ∆t 𝑣,𝑝 . After referring to Table 1, we decided to

use 95% as our confidence intervals, besides v =N-1=4-1=1, so t 𝑣,𝑝 = 3.182. Sx ,which is the value of

standard distribution, equals to 0.30561

Example answer for

𝐷 = 46.34 ± 0.4862(95%)

Measurement Number

Diameter, D (mm)

1

46.01

2

46.6

3

46.6

4

46.15

Average

46.34

Standard deviation(Sx)

0.30561

tv,p

3.182

∆x

0.48622551

Table 3: This table lists the data that is used to calculate uncertainties for tube diameter Dt

b. Calculate uncertainties ∆𝑈∞ when ∆𝑑, ∆𝐷, ∆U𝑡 is known, use sphere 1 as an example

2

2

2

𝜕𝑈∞

𝜕𝑈∞

𝜕𝑈∞

∆𝑈∞ = √(

∆𝑑) + (

∆𝐷) + (

∆𝑈𝑡 )

𝜕𝑑

𝜕𝐷

𝜕𝑈𝑡

13

13

9

𝑑 −4

1

9

𝑑 −4

1

(𝑑 ∗ 𝐷−2 )∆𝐷]2 + [

= √[− 𝑈𝑡 (1 − )

(− ) ∆𝑑]2 + [− 𝑈𝑡 (1 − )

∆𝑈 ]2

𝑑 9 𝑡

4

𝐷

𝐷

4

𝐷

(1 − )4

𝐷

13

13

9

3.173 − 4

1

9

3.173 − 4

1

2

(3.173 ∗ 46.34−2 )∆46.34]2 + [

= √[− 815.85 (1 −

)

(−

) 0.4862]2 + [− 15.85 (1 −

)

9 0.1524]

4

46.34

46.34

4

46.34

3.173 4

(1 −

)

46.34

= 0.3572

sphere 1

sphere 2

mean

∆x

mean

∆x

d (mm)

3.173

0.03173

d (mm)

3.173

0.03173

D(mm)

46.34

0.48622551

D(mm)

46.34

0.48622551

Ut(mm/s)

15.85

0.152457096

Ut(mm/s)

39.5

0.727442772

U∞(mm/s)

18.59

0.3572

U∞(mm/s)

46.33

0.8598

sphere 3

mean

∆x

d (mm)

1.583

0.01583

D(mm)

46.34

0.48622551

Ut(mm/s)

10.8

0.053350424

U∞(mm/s)

11.67

0.0592

Table 4: This table lists the data that is used to calculate uncertainties for U∞ for sphere 1, 2 and 3

respectively.

4. Calculate the uncertainties for 𝜇

Governing equations:

𝜇=

(𝜌𝑠 − 𝜌𝑓 )𝑔𝑑2

18𝑈∞

Use sphere 1 as an example:

2

𝜕𝑢

∆𝜌𝑠 )

𝜕𝜌𝑠

∆𝑢 = √(

2

𝜕𝑢

∆𝑓)

𝜕𝑓

+(

(𝜌 −𝜌 )𝑔2𝑑

𝑔𝑑 2

∆𝜌𝑠 )2 + 0 + [ 𝑠 𝑓

∆𝑑]2

18𝑈∞

18𝑈∞

(3990−1262.24)∗9.81∗2∗0.003173

√(

0+[

18∗0.01859

2

𝜕𝑢

∆𝑑)

𝜕𝑑

+(

𝜕𝑢

∆𝑈∞ )2

𝜕𝑈∞

+(

(𝜌𝑠 −𝜌𝑓 )𝑔𝑑 2

+[

18

9.81∗0.0031732

18∗0.01859

(3990−1262.24)9.81∗0.0031732

(−𝑈∞ −2 ) ∗ ∆𝑈∞ ]2 = {(

∗ 0.00003173]2 + [

0.0003572]2 }^0.5=0.028

Sphere 1

=

mean

∆x

U∞

0.01859

0.0003572

d (m)

0.003173

0.00003173

ρ(kg/m3)

3990

79.8

ρf(kg/m3)

1262.24

0

μ(N*s/m2)

0.805125187

0.0285

18

∗ 79.8)2 +

(−0.01859−2 ) ∗

Sphere 2

mean

∆x

U∞

0.04633

0.0008598

d (m)

0.003169

0.00003169

ρ(kg/m3)

8000

160

ρf(kg/m3)

1262.24

0

μ(N*s/m2)

0.795965451

0.0247

mean

∆x

U∞

0.01167

0.0000592

d (m)

0.001583

0.00001583

ρ(kg/m3)

8040

160.8

ρf(kg/m3)

1262.24

0

μ(N*s/m2)

0.793183484

0.02461

Sphere 3

Table 5: This table lists the data that is used to calculate uncertainties for dynamic viscosity of fluid μ for

sphere 1, sphere 2, sphere 3 repectively.

CONCLUSION

This experiment illustrates the validity of Eqn 1, where the

is stated to be linearly related to

the difference between the fluid and sphere densities, and quadratically related to “d”, the diameter of

the sphere. This is confirmed earlier by comparing the two steel spheres of roughly similar densities and

with one diameter roughly half of the other, which made the correlation of

with “d” or the diameter

clear, while the large red plastic sphere and the large steel sphere had their densities, one exactly half of

the other, which established the correlation of

with density.

Also, the Stokes Equation formulation for

for a sphere in Eqn 1 yielded results closely

averaging around 0.8 N·s/m2, which correlated rather well with the predicted dynamic viscosity using

Eqn 9, which predicted

to be around 1.0 N·s/m2. The 20% is expected for such fluid-type

experiments, however, certain sources of uncertainty and deviance were offered. Namely, the effect of

averaging velocities from Segment 2 and 3 of the tubes, both of which may not truly reflect the terminal

velocity. There is also the issue of the spheres traveling slanted paths closer to the wall and the effect

that might have on the correction factor used, which takes into account the finite dimensions of the

tube and possibly the wall shear resulting from it but doesn’t account for the ball traveling off-center.

Finally, there is the fact that Eqn 9 was specifically developed in a separate experiment that involve

adopting a “Falling Needle Viscometer” type setup rather than a “Falling Sphere Viscometer” setup like

our experiment, for the purposes of not developing inaccuracy from uncertainties in sphere diameter or

density. As a result, the predicted dynamic viscosities for the fluid in Eqn 9 are likely truer values,

however, the experimental dynamic viscosities calculated using Eqn 1 do make sense when considering

the slanted path the spheres in this experiment took and the other uncertainties that our setup was not

free of.

With regards to the latter objective of this experiment, a fairly linear log-log plot was

established for log of the

against the log of the

, and this means our experimental results can

be used to predict both quantities for a given sphere diameter and density, assuming that this will

satisfy the condition of

< 0.1 which this experiment required and that the log of

and log

point falls within the laminar region of the curve that was developed in this experiment. Interpolating in

this linear region will yield valid results but outside of this region could be a transition to the turbulent

region, where predictions from the current data cannot be made.

This experiment would benefit from the use of a slender cylinder model as was done in the

paper that established Eqn 9, as this type of an object would be more likely to follow a more linear

trajectory down center and avoid issues of different apparent tube “D” and inaccuracies in velocities

calculated, since slanted paths would mean the true distance traveled in a segment would not simply be

the length of the segment. Although the drag coefficient for such a model may be higher, if a Stokes

equation-type formulation exists, it should yield consistent dynamic viscosity values, and will likely

match the values predicted from Eqn 9.

REFERENCES

1. Pritchard, Philip J, Fox and Mcdonald’s Introduction to Fluid Mechanics, 8th Ed. Wiley, October

2011. P38-40

2. Yunus A. Cengel and Afshin J. Ghajar, Heat and Mass Transfer Fundamentls and Applications 4th

Ed., McGraw-Hill 2011, p.373-385

3. Igor N, Serdyuk, Nathan R. Zaccai, and Joseph Zaccai, Methods in Molecular Biophysics:

Structure, Dynamics, and Function. Cambridge Unversity Press, March 29th 2007. P255-256

4. Griggs, Andrew J., The Low-Reynolds-number motion of Drops and Bubbles Near Solid Planar

Surfaces. Proquest Information and Learning Company, 2008. P102-104

5. Park, N.A. and T.F. Irvine, Jr., “The Falling Needle Viscometer: A New Technique for Viscosity

Measurements,” Warme-und Stoffubertragund, Vol. 18, pp. 201-206 (1983).