Heat Stress and Laminitis in Dairy Cows

advertisement

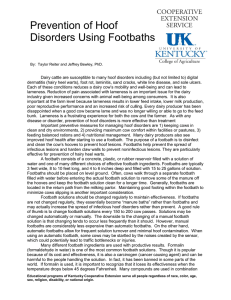

Proper Footbath Design and Management Critical For Controlling Infectious Claw Lesions Many dairy producers rely on footbath programs to help prevent and control infectious claw lesions in their herd. Maximizing the effectiveness of a footbath program hinges on several key factors including proper footbath design and effective footbath management techniques. “When used correctly, footbath programs can be a highly successful way for dairies to help prevent and control the spread of infectious lesions such as digital dermatitis, interdigital dermatitis and foot rot,” says Dr. Dana Tomlinson, Research Nutritionist, Zinpro Corporation. “However, a poorly managed footbath program can actually cause more harm than good.” Dr. Tomlinson offers the following guidelines when evaluating the effectiveness of a footbath program: Design Considerations Footbath units should be eight to ten feet (2.5 to 3 meters) long, with a minimum depth of six inches (15 cm). The footbath structure should also be wide enough that all four of the cow’s feet get exposure to the footbath solution. The footbath solution should be four to six inches (10 to 15 cm) deep to ensure adequate coverage of the foot area. Research supporting the value of pre-bath solutions is limited. Consider filling both pre-bath and treatment bath with the treatment chemical to increase exposure to the treatment solution. If different solutions are used in the pre-bath and treatment bath, there should be a gap of 6 to 8 feet (2 meters) between the two baths to prevent the pre-bath solution from diluting, and hence decreasing the efficacy of the treatment bath solution. On days when footbaths are not filled with a treatment solution, consider filling the pre-bath (if used) and treatment bath with a 1% mild soap solution. Ensure that footbaths are located on a level surface. Floors should provide adequate traction, but not be rough and abrasive, which may cause trauma to a cow’s feet. Management Considerations Footbaths should be used 3 to 4 days per week. Foot and leg hygiene help determine the number of days required, as dirtier cows require more footbathing. Locate the footbath in an area regularly traveled by cattle. Ensure that cows have the ability to bypass permanent footbath areas on days when footbaths are not being used. Cows should enter a clean dry area after passing through a footbath. Change footbath solution after every 150 to 200 cows. This frequency will vary depending upon cow cleanliness, use of a pre-bath, type of disinfectant or chemical concentration used and weather conditions. Alternate times for replenishing footbaths with fresh solution so each group of cows has access to fresh solution. Thoroughly drain footbath and rinse with water before mixing a new batch of solution. Use claw lesion records to monitor effectiveness of footbath management and efficacy of footbath solutions. Dr. Tomlinson also stresses the importance of accurately calculating the capacity of a footbath (3-step calculation process shown in Figure 1; Example calculation shown in Figure 2). “For footbaths to be effective, it is critical that the right amount of product is added to the footbath solution. In arid regions, evaporation will concentrate the active ingredients.” In addition, Dr. Tomlinson reminds producers of the critical role that trace mineral nutrition plays in building and maintaining strong, healthy feet. For example, zinc and copper are essential nutrients for developing healthy claw horn tissue; while zinc and manganese play a crucial role in wound healing. Research has shown that feeding a combination of trace minerals (Zn, Mn, Cu and Co) in a highly available complexed form helps decrease both the incidence and severity of common claw lesions. As the leader in trace mineral nutrition, Zinpro is committed to delivering the people, products and educational tools needed to help customers improve the performance and profitability of their operation. Figure 1. Common Footbath Calculations Type of Calculation: How To Calculate: (imperial units) How To Calculate: (metric units) Multiply: Length (ft) X Multiply: Length (m) X width (ft) x depth (ft) X 7.46 width (m) X depth (m) X = number of gallons 1000 = number of liters Multiply: Number of gallons Number of liters X 8.33 = pounds of water = kg of water Multiply: Pounds of water X Multiply: kg) of dry product percent solution desired = Kg of water X percent needed to achieve the pounds of dry product solution desired = kg of dry desired solution to add product to add 1. Determine capacity of a footbath 2. Convert gallons to pounds (or liters to kg) 3. Determine pounds (or Figure 2 (imperial). Example Calculation How many pounds of dry product are needed to achieve a 5% copper sulfate solution in a footbath that measures 10 ft long, 3 ft wide and 6 inches deep? o Answer: 46.6 lb of copper sulfate. How To Calculate This: Step 1: 10 X 3 X 0.5 X 7.46 = 111.9 gallons Step 2: 111.9 gallons X 8.33 = 932.1 lb of water Step 3: 932.1 X 0.05 [5% solution] = 46.6 lb of copper sulfate Figure 2 (metric). Example Calculation How many kg of dry product are needed to achieve a 5% copper sulfate solution in a footbath that measures 3 meters long, 0.9 meters wide and 0.15 meters deep? o Answer: 20.25 kg of copper sulfate. How To Calculate This: Step 1: 3 X 0.9 X 0.15 X 1000 = 405 liters Step 2: 405 liters of water = 405 kg of water Step 3: 405 X 0.05 [5% solution] = 20.25 kg of copper sulfate

![[Download MSDS] (.doc)](http://s3.studylib.net/store/data/006712111_1-6d2aee48fdad537db5a64f921a9ed630-300x300.png)