ShapingBits announces 3FXtrud Duo family of fully featured dual

advertisement

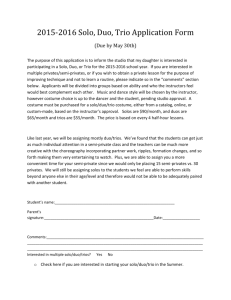

Prepared by: ShapingBits shapingbits.com Contact: Bogdan Diaconescu bogdan@shapingbits.com +1 702-660-9013 ShapingBits announces 3FXtrud Duo desktop 3D printer with advanced features for true free-form and multi-material additive manufacturing Albuquerque, NM April 14, 2015 – ShapingBits is announcing the release of 3FXtrud Duo, the companion of user-friendly single extruder 3FXtrud Uno. The new 3FXtrud Duo is a fully featured 3D printer, designed to push the boundary of what is achievable with desktop additive manufacturing. 3FXtrud Duo is a dual extruder, true free-form fabrication 3D printer, with advanced features for 3D printing with the largest variety of engineering thermoplastic materials, a tool for professionals wanting the most capability within one system. It builds functional objects with material properties matching your applications, from soft and compressible (rubbery) to hard and high strength, and from low to high melting temperature. It is the next generation of multi-material capable, high resolution, fast, safe, commercial grade, and easy to use desktop 3D printer. The quality of the 3D printed objects depends heavily on the positional accuracy of the printing head with respect to the printing platform, the precision with which the material is deposited, the range of materials supported, which translates in the desired physical properties of the object printed, and ability to control the environment around the building platform to reduce thermal stresses in between the 3D printed layers of materials, therefore improving part's strength. ShapingBits 3FXtrud Dou printers set a new standard in positional accuracy, material deposition control, have the largest range of materials supported for a desktop 3D printer, and provide thorough control of the printing environment. At the core of 3FXtrud Duo is an advanced multi-material dual extruder printing head with an allmetal construction that excels at printing the largest range of thermoplastics, from renewable to specialty engineering grade thermoplastics. It was specifically designed to print thermoplastic materials with very different physical properties, from high-strength specialty engineering thermoplastics to flexible to soft (rubbery), from low temperature renewable plastics to high temperature engineering materials. It can print FDA approved materials. The extruders on the ShapingBits 3FXtrud Duo have been designed to provide low maintenance and prolonged utilization, by reducing stripping, skipping and jamming, and employs a tool-less constant force filament feeding system that is simple to use and setup for different materials. True Free-Form Fabrication (3F) can be achieved when any shape can be printed. 3FXtrud Duo uses a multi-material dual extruder thus can print a large number of thermoplastics along with any two combinations of such materials. With 3FXtrud Duo you can print any 3D geometry with overhangs, bridges, internal spaces with internal objects, all possible by using dissolvable support materials. A high temperature heated bed that can sustain up to 130 °C continuously with an extremely flat removable glass surface is used for improved adhesion and to prevent warping for a large range of thermoplastic materials. A fully enclosed build volume that eliminates air drafts and provides a stable air temperature profile by trapping the heat is improving 3D printed object’s quality by minimizing interlayer stress in the built objects which results in stronger parts. The users have the option of installing a particle and activated carbon air filter with air temperature homogenizer for odor free operation and even more uniform temperature profile for the enclosure, and, for the mavericks wanting even more control and desire to work with experimental materials, a closed loop air temperature conditioner for extended enclosure air temperature range. Supported materials at this moment are: ABS (Acrylonitrile butadiene styrene), Nylon (aliphatic polyamides), TPU (thermoplastic polyurethane), TPE (Thermoplastic elastomers), PC (Polycarbonate), PC-ABS (Polycarbonate - ABS blends), HIPS (High Impact Polystyrene), PVA (Polyvinyl alcohol), PLA (Polylactic acid), PETT poly(ethylene-co-trimethylene terephthalate), PLA metal/ceramics blends, PLA wood, PLA Carbon Fiber, PLA Conductive, ABS Conductive. FDA approved materials can also be 3d printed. 3FXtrud Dou are the evolutive result of five+ generations of 3D printers extensively tested with every single supported material. Some of our previous printers are in use by makers and engineers in their homes, research labs, companies (from Sandia National Labs to toy companies), and universities. ShapingBits develops and markets desktop 3D printers and their multi-material 3D printers are used by makers, engineers, and researchers in their homes, research labs, companies, and universities (from Sandia National Laboratory to toy companies to R/C scale parts shops). For additional information please visit www.shapingbits.com. ###