Sharps disposal

advertisement

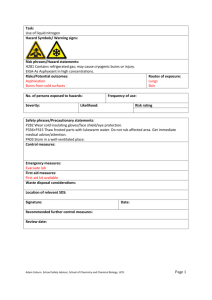

Health and Safety Risk management form Faculty/Division: Science School/Unit: School Initial Issue date: 21/08/2013 Document number Risk Assessment name Current version: 1 of Biological Sciences Current Version Issue date Next review date: 21/08/2013 21/08/2016 Sharps disposal Form completed by Anne-Laure Markovina Signature Responsible supervisor/ authorising officer Michael Joseph Signature Identify the activity and the location of the activity Description of activity Sharps include razor blades, needles, slides and coverslips and plastic pipette tips. Students use razor blades to cut plant and animal specimens; needles to collect toad blood, slides and coverslips when mounting biological specimens; plastic pipette tips to dispense chemicals and/or bacteriological cultures Description of location Sharps are used in 2nd and 3rd year teaching laboratories in Old Geology (A11), rooms 204 & 205a; Macleay (A12), rooms 204 & 207; Badham (A16), rooms 222a, 222b, 227 and in First Year Biology in Carslaw (F07), rooms 301; 302, 307; 308 Identify who may be at risk from the activity: This may include fellow workers, visitors, contractors and the public. The types of people may affect the risk controls needed and the location may affect the number of people at risk Persons at risk Undergraduate and postgraduate students, research and staff How they were consulted on the risk Technical staff is responsible for assessing risk and updating risk assessments before a task is undertaken. Technical staff advises supervising and academic staff of potential risk before practical class. Academics in charge inform demonstrators and students about the risks. Up to date risk assessments are posted on the School’s website and are displayed in the class on the day of the practical List legislation, standards, codes of practice, manufacturer’s guidance etc used to determine control measures necessary Work Health and Safety Act 2011 Work Health and Safety Regulation 2011 Laboratory Safety Guidelines http://sydney.edu.au/whs/guidelines/others/laboratory_safety.shtml Technical instruction in Laboratory Manuals and BlackBoard on-line system – updated annually 1|P a g e Consider the hierarchy of hazard control and record what controls will be used in the short term and longer term Elimination Not possible Eliminate the hazard or task if the risk outweighs the potential benefits. Substitution Not possible Substitute the hazard with something less hazardous e.g. less toxic substance. Isolation Possible Isolate the hazard by using barriers or distance – When working with dangerous chemicals or bacterial cultures, work in fumehood or laminar flow cabinet Engineering Not possible Look for physical design solutions, controls, safety lockouts or automation to reduce or eliminate risks. Minimise Not possible Minimise the size or volume of the hazard or time of exposure to the hazard. Rearrange Workflow Not possible Rearrange activities to minimise lifting/handling/overuse injuries Administrative Possible Establish Safe Work Practices e.g. restrict access, have Safe Work Practice documentation and procedures for hazardous tasks. Training and Supervision Possible Provide training and supervision appropriate to level of expertise of the person(s) involved. Record training in SWP. Personal Protective Equipment Possible Use only as a secondary measure to supplement other risk controls e.g. gloves, lab coats, safety glasses. Identify hazards and control the risks. 1. An activity may be divided into tasks. For each task identify the hazards and associated risks. Also list the possible scenarios which could sooner or later cause harm. 2. Determine controls necessary based on legislation, codes of practice, Australian standards, manufacturer’s instructions etc. 3. List existing risk controls and any additional controls that need to be implemented Task or Hazard Associated harm Existing risk controls Scenario Hand sectioning of fresh plant material Use of sharp, single-sided razor blades Cut to fingers and/or hands Plant samples are placed within a support material, e.g. a potato, which provides extra hand protection for very small samples In addition, a set of instructions (SOP) is provided in the students’ lab manual and on BlackBoard Hand sectioning of fresh animal material Use of sharp, single-sided razor blades Cut to fingers and/or hands Students are provided with gloves and goggles and dissect specimens in wax dishes to stabilize specimens Collecting blood from cane toads Use of syringes and needles Puncture wound to hands and/or fingers Students are provided with gloves and goggles A set of instruction for dissecting animals (SOP) is provided before practical class Current risk Any additional controls required? Residual risk Medium None Low Medium None/PPE and risk assessments for poisonous animals (cane toads) Low Medium 2|P a g e Task or Hazard Associated harm Existing risk controls Scenario Current risk Any additional controls required? Residual risk List emergency procedures and controls List emergency controls for how to deal with fires, spills or exposure to hazardous substances and/or emergency shutdown procedures Work Health and Safety Act 2011 Work Health and Safety Regulation 2011 Laboratory Safety Guidelines http://sydney.edu.au/whs/guidelines/others/laboratory_safety.shtml Technical instruction in Laboratory Manuals and BlackBoard on-line system – updated annually Implementation Additional control measures needed: REVIEW Scheduled review date: Are all control measures in place? Resources required Responsible person 12 months 2 years Date of implementation 3 years Are controls eliminating or minimising the risk? Are there any new problems with the risk? Review by: (name) Review date: Acknowledgement of Understanding All persons performing these tasks must sign that they have read and understood the risk management. Note: for activities which are low risk or include a large group of people (e.g. open days, BBQ’s, student classes etc), only the persons undertaking the key activities need to sign below. For all others involved in such 3|P a g e activities, the information can be covered by other methods including for example a safety briefing, induction, and/or safety information sheet (ensure the method of communicating this information is specified here) Risk management name and version number: Name V1 I have read and understand this risk management form Signature Date 4|P a g e