SI - AIP FTP Server

advertisement

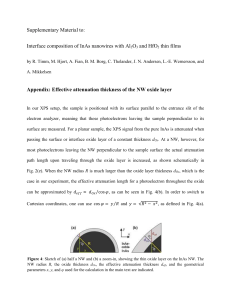

Supplementary Information Contactless derivation of inner fields in gate-oxide layers: SiO2 on SiC Alon Givon1, Hong Piao2, James McMahon2, Gilad Zorn2, Hagai Cohen3* 1. Department of Materials and Interfaces, Weizmann Institute of Science, Rehovot, Israel 76100 2. GE Global Research, General Electric Co., Niskayuna, NY 12309, USA 3. Chemical Research Support, Weizmann Institute of Science, Rehovot, Israel 76100 Sample preparation and characterization Samples were fabricated on a Si-face (0001) 4H-SiC substrate with a 1μm p-type epi layer doping of 9.5x1016 cm-3. Oxidation was processed in dry O2 at 1100˚C. Initial thickness was nominally 50nm and oxide thinning down to ~5nm thickness was then accomplished via wet etching in dilute hydrofluoric acid. Removal of the back-side oxide was then processed and, for comparison, a back metal contact was added to part of the samples. Film thickness mapping by means of optical reflection spectrometry in a Nanospec AFT film thickness measurement system was used as a follow-up of the thinning process, complementary to the in-situ x-ray photoelectron spectroscopy (XPS) analyses. Due to the thinning process, the question of surface roughness is of particular relevance. Fig. S1 presents maps of the optically measured thickness across samples 1 and 2. Table S1 presents the XPS derived thicknesses at selected spots and the corresponding optically derived values. A reasonably good agreement is obtained between the two techniques, suggesting that changes in the dielectric constant do not have a large effect. The total thickness variations found in sample 1 are within ±1nm, around a mean value of ~5.5 nm. However, only ±0.5nm variations (on a macroscopic lateral scale) are relevant for our measurements at the central areas. A significantly thinner oxide is found in Sample 2, showing a roughly similar non-uniformity around the central domains. Interestingly, however, our CREM data reveals a marked difference in dielectric quality, not accounted for by the thickness data. It is therefore suspected that pinholes appear on a microscopic scale in sample 2, which affects the calculated average thickness (as extracted from relatively large areas) only slightly; however imposes a marked effect on the dielectric properties. The latter is easily captured by CREM, as demonstrated in Fig. 3 and in measurements under lower VG values (not shown), whereas the optical probe is essentially blind to such effects. Samples of different preparation procedures, including NO-annealing, have been also prepared, however due to difficulties in controlling the thinning process, are not discussed here. This paper focuses on the characterization technique and the type of sample properties it can probe, with no intention to gain solid insight on the sample preparation processes. Table S1:Oxide thickness values (given in nm) at selected measuring points in samples 1 and 2, as derived by XPS and by optical reflection. Note the general agreement between the two techniques. Complementary data is given in Fig. S1 Figure S1: Optical maps of the oxide thickness in sample 1 (left) and sample 2 (right), as derived from 3x10 point measurements equally spaced across the sample. The indicated small circles stand for the discrete points of XPS/CREM measurements, 1-4 in sample 1 and 1-3 in sample 2. Their diameter (0.5 mm) roughly matches the size of XPS analysis area. The large, green circles indicate the electron flood gun (eFG) spot size (~ 5 mm); plotted specifically on those points from which the data shown in Figures 2-4 was recorded. Note the non-negligible thickness variations taking place on a macroscopic scale. CREM data acquisition, processing and simulations Measurements were performed in the slot mode of the Vision software, with which the analysis spot is about 0.5 mm in diameter. The electron flood gun (eFG) spot size is about 5 mm in diameter (see Fig. S1), hence lateral uniformity of the applied field is expected. More critical for the lateral uniformity in our measurements is the fact that the electrons supplied by the eFG are of relatively high energy (i.e. above vacuum level). Therefore, they would rapidly redistribute under any lateral field to preserve uniform surface potential. In this respect, one may draw close similarity between the eFG and a standard metallic top contact. However, it should be stressed that the eFG electrons are of energy far above the Fermi energy, which imposes important consequences as of the probed electrical properties1. The extractions of CREM data from measured spectra, as well as line-shape & shift simulations, were performed using Matlab based algorithms. Two complementary methods were used to extract the energy shift of a spectral line, compared to a reference line: (1) measuring the energy difference between the two inspected peak (intensity maximum) positions; (2) evaluating the shift between lines at their sides, where the slope is maximal. The main drawback of the first method is that it is subject to limited accuracy, as dictated by the line width, shape asymmetry and noise. In this respect, the second method is by far more accurate when the shift is smaller than the line width. The first method becomes more efficient, or at least an important complementary input, when the signal of interest overlaps with other signals. For the second method, about 50 data points on each side of the line were first selected for a moderate smoothing step. Shift evaluation was then performed separately for the right (low EB) side and the left (high EB) side of each line and, then, an average value was calculated. Analysis of the electric field within the oxide layer was conducted using an iterative curvefitting algorithm, based on equations 2-4. The algorithm employs a Matlab built-in optimization function lsqcurvefit for nonlinear curve-fitting at the ‘trust-region-reflective’ mode. Two boundary conditions were applied, extracted from the Si 2p and C 1s signals of the substrate and top adventitious molecules, thus reducing the number of free parameters. The remaining free parameters included two field strength values and two z-interface locations (a third field component was determined by the independently derived V0 and d value). The effect of surface roughness (see Fig. S1 and Table S1) was explicitly inspected for determining the limits of our model-based simulations. We find that, for the present characterization results, the roughness cannot have a significant effect on line-shape. Fig. S2 presents a specific example where two line-shapes are compared, one of them calculated for an ideally flat surface and the other for thickness variations of 1nm, i.e. ~10% of the mean value. The simulated spectra show an extremely small difference in line-shape. Figure S2: Simulated line-shapes for the O 1s line under VG=5 V, comparing an ideally uniform layer with a layer consisting of 1 nm thickness variations Why is the effect in Fig. S2 so small? The simulated line shapes were computed under the assumption that (1) integrated XPS intensities are not altered (namely, the experimental data should hold for any roughness parameter in the simulation); and (2) lateral potential equalization is maintained, for reasons discussed above. These restrictions limit the freedom of parameters and eventually do not give rise to large variations in line shape. In contrast, a more pronounced appearance of lateral heterogeneities is enabled under rapid fluctuations in the time domain; effects that should be demonstrated and discussed separately, inspecting samples under extreme field conditions. Another question may be raised regarding the evolution of vertical potential differences, specifically between adventitious carbon atoms and the top of the underlying oxide. A number of CREM works on organic monolayers have focused on these effects. So far, summarizing a large number of experiments on a broad range of systems, we have found such differences to remain relatively small, below 100 meV, for typical contamination moieties (hydrocarbons mainly) at thicknesses similar to what we have here. The derivation of carbon impurity profiles Carbon impurity profiles were extracted as follows: 1. Defining the top and substrate carbon components from the spectra recorded under extreme conditions, namely the one at the highest field (with VG=5V) and the one obtained with eFG-off. The differentiation between oxidation state and electrostatic energy, namely between the EB and the eV terms, could thus be obtained more reliably. 2. Determining the impurity signal via standard curve fitting subroutines. 3. The above carbon signal decomposition (into three major components, Csub, Ctop and Cimp) was checked for consistency among the various steps in eFG conditions, for which both intensities and line-shifts (or stretching & broadening) were considered. 4. Due to technical considerations in the curve fitting process, we used a small number (4 only) of Cimp electrostatically different components. These components were good enough to practically reproduce the Cimp line-shape, even though they necessarily originated from a continuous profile. 5. The extracted line shape was corrected for attenuation (multiplying by A-1, see text) to get the actual profile shape. 6. Broadening (via convolution with a Gaussian of FWHM=1.5 nm) was applied to the derived profile, to compensate for the limited, discrete number of components. 7. The impurity scale was finally normalized such as to retain the measured concentration within the entire oxide. A few comments should be made : 1. The accuracy of the derived profile is improved at higher fields. 2. Due to the fact that a few discrete components represent a continuous profile, a systematic error is encountered at the inner interface, z=d. The variations in Cimp concentration along the inner 1 nm (just above the substrate, see Fig. 4b), under high fields in particular, are therefore suspected to largely reflect an artifact of the analysissimplification used here. 3. In continuation to the above point, part of the increase in total amount of impurities may be associated with the same artifact. 4. Irreversible changes in the sample were observed during the entire set of measurements in Fig. 4a, mainly the removal of oxidized CTop species and an increase in Cimp. As discussed in the manuscript, these changes introduced an additional limitation on the accuracy of the derived profiles. 5. Two chemically different components were found to coexist in the impurity signal Cimp. 6. Technically, the ratio between the O 1s and the C 1s signals was used to calculate the total amount of carbon impurity in the silica. 𝐶 𝑖𝑚𝑝 (%) = 𝐶1𝑠 × 𝐼𝑖𝑚𝑝 1.5 × 𝑂1𝑠 where C1s and O1s are the percentages of C 1s and O 1s signals respectively, 𝐼imp is the percentage of the impurity signal relative to the total C signal and the 1.5 factor at the denominator accounts for the SiO2 stoichiometry. Fig. S3: The Si 2p line shape under varying eFG stimuli: (a) the various Si 2p lines, recorded under VG=off, 2.2 V, 2.7 V, 3.2 V, 3.7 V, 4.2 V, 4.7 V and 5.0 V, demonstrating relatively small shifts of the substrate component (SiC), while the oxide component (SiO2) broadens and shifts much more pronouncedly. (b) The Si 2p line shape under VG=5.0 V, showing the substrate (red curve) and oxide (blue curve) components. Note the similarity of the latter with that of the oxygen, shown in the inset. References 1 A. Rozenblat, Y. Rosenwaks and H. Cohen, APL 94, 213501 (2009)