Appendix - I 1. Mathematical models for Combustion analysis Based

advertisement

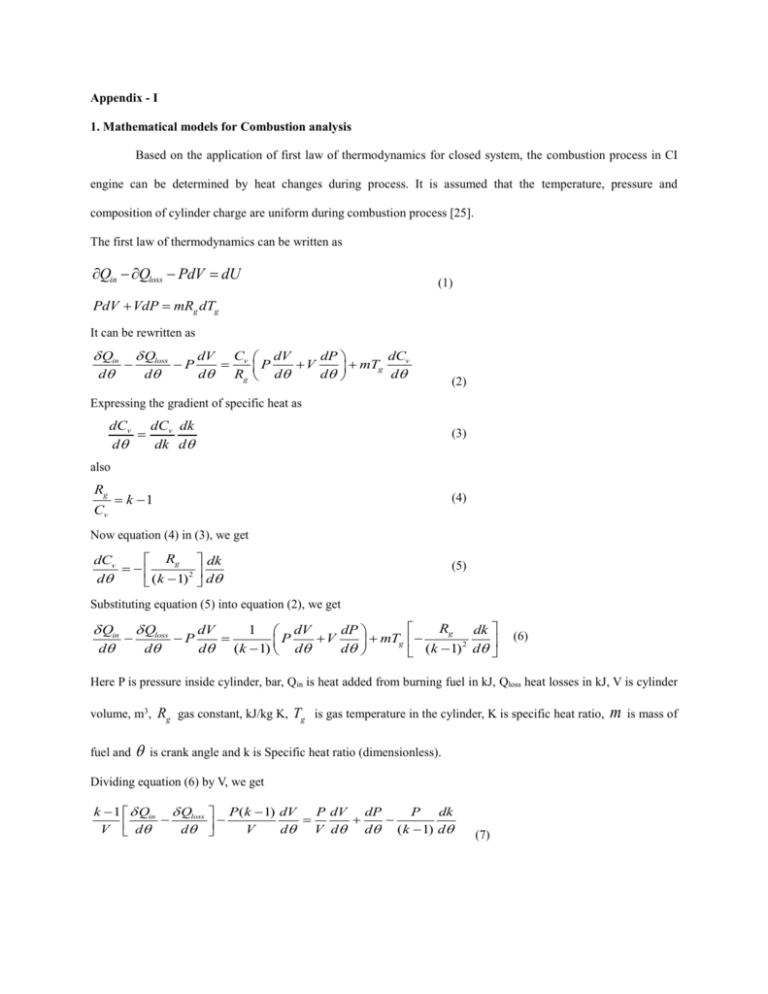

Appendix - I 1. Mathematical models for Combustion analysis Based on the application of first law of thermodynamics for closed system, the combustion process in CI engine can be determined by heat changes during process. It is assumed that the temperature, pressure and composition of cylinder charge are uniform during combustion process [25]. The first law of thermodynamics can be written as Qin Qloss PdV dU (1) PdV VdP mRg dTg It can be rewritten as Qin Qloss C dV P v d d d Rg dCv dP dV V P mTg d d d (2) Expressing the gradient of specific heat as dCv dCv dk d dk d (3) also Rg Cv k 1 (4) Now equation (4) in (3), we get Rg dk dCv 2 d (k 1) d (5) Substituting equation (5) into equation (2), we get Rg Qin Qloss dV 1 dV dP dk P V P mTg 2 d d d (k 1) d d (k 1) d (6) Here P is pressure inside cylinder, bar, Qin is heat added from burning fuel in kJ, Qloss heat losses in kJ, V is cylinder volume, m3, Rg gas constant, kJ/kg K, Tg is gas temperature in the cylinder, K is specific heat ratio, fuel and is crank angle and k is Specific heat ratio (dimensionless). Dividing equation (6) by V, we get k 1 Qin Qloss P (k 1) dV P dV dP P dk V d d V d V d d (k 1) d (7) m is mass of Here, Qin is heat input in the system, Qloss is heat loss across the system, dCv change in specific heat at d d d constant volume, dV change in volume, dP change in pressure, d d dk Negligible d Hence, equation (7) can be rewritten as P dV dP k 1 Qin Qloss k d V d d V d (8) This relation makes it possible to calculate change in pressure inside the cylinder during combustion process with respect to crank angle. Qin ( ) m fb ( ) LHV Qloss hcg A T ( ) Tw (t ) Here Qin(θ) is the amount of heat produced due to fuel burned , Q loss is the heat loss from the engine by cooling water and engine wall. The hcg is heat transfer coefficient which is computed by using well known Woschnis equation describe in later section. [ 25 - 26] T ( ) P( ) V( ) mRg V ( ) Vc D 4 2 x1 ( ) (9) where x1(θ) is variation in length of stroke with crank angle D A( ) 2 Dx1 ( ) 4 2 V(θ) can be written as V ( ) Vc D2 4 2 lc 1 R 1 cos 1 R 2 sin( ) Vc (10) V ( ) 2.1 Combustion (Burned and Unburned Zone) The weibe function is used for calculation of heat release rate due to combustion of fuel and it is based on the exponential rate of the chemical reaction [27] o m p 1 X 1 exp a By differentiating the equation, the rate of heat release rate is calculated as m o m p 1 dQR Q o a m 1 av exp a d here ∆ (θ) is duration of combustion in crank angle, θ is crank angle at any instant, θo is a crank angle at start of combustion and Qav is heat release per cycle in KJ. Here ‘a’ is an adjustable parameter for characterizing the completeness of combustion. (Weibe assumed X max = 0.990) and m is the parameter for characterizing the rate of combustion. [23, 27] The Burned and unburned gas temperatures can be obtained using equation (9). The volume fraction of the burned gas yb xb ( ) 1 1 b yb u 1 Vb can be obtained by using following equation V 1 u = 4.0 was used for the sake of simplicity u = density of unburned charge, b = density of burned charge, the b ratio of u affect the burned gas temperature. b 2.2 Heat transfer The heat transfer between the working fluid and the surrounding wall has force convection. It is computed by using well proven Woschnis correlation [25 - 26]. hcg 3.26D0.2 P0.8T 0.55W 0.8 The velocity of burned gases. W S p c1 Vd Tr prVr ( p( ) pm ) where, Sp is piston speed m/s, Tr, pr and Vr are reference state properties. pm pressure at same position and C1 (compression process)=0 and C1 = 0.00324 for other two process (combustion and expansion) [25 - 28]